We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-01-12 Origin: Site

Mechanical draught cooling towers may look like simple industrial structures, but in reality, they are carefully engineered systems where structural design determines performance, safety, and service life. Behind every efficient cooling tower is a framework that supports heavy water loads, rotating mechanical equipment, airflow forces, and harsh outdoor environments—often for decades.

In this article, we’ll take a deep dive into the structural design of mechanical draught cooling towers, explaining how each structural element works, what engineers must consider, and why experienced manufacturers like Mach Cooling play a vital role in long-term reliability.

At its core, a mechanical draught cooling tower uses fans to move air through the system, accelerating heat transfer between water and atmosphere. That simple idea creates a complex structural challenge.

Unlike natural draught towers that rely on height and buoyancy, mechanical draught towers must handle:

Continuous vibration from fans and motors

Dynamic airflow forces

Concentrated equipment loads

Constant exposure to water and chemicals

This makes structural design not just important—but essential.

Think of a cooling tower like a house built on weak foundations. It may stand at first, but cracks, misalignment, and failures are inevitable.

Poor structural design can result in:

Excessive vibration and noise

Fan and gearbox misalignment

Basin leakage and deformation

Premature failure of internal components

A well-designed structure, however, allows the cooling tower to operate smoothly, quietly, and efficiently for many years.

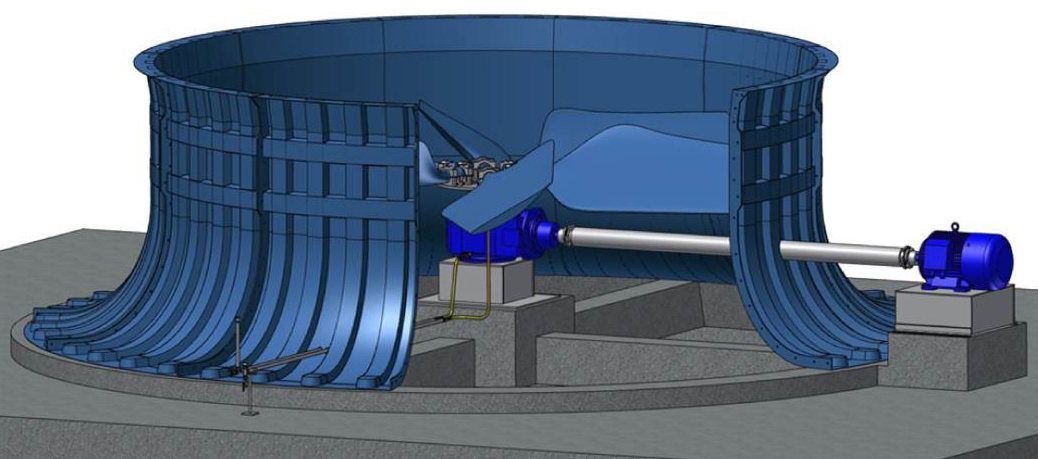

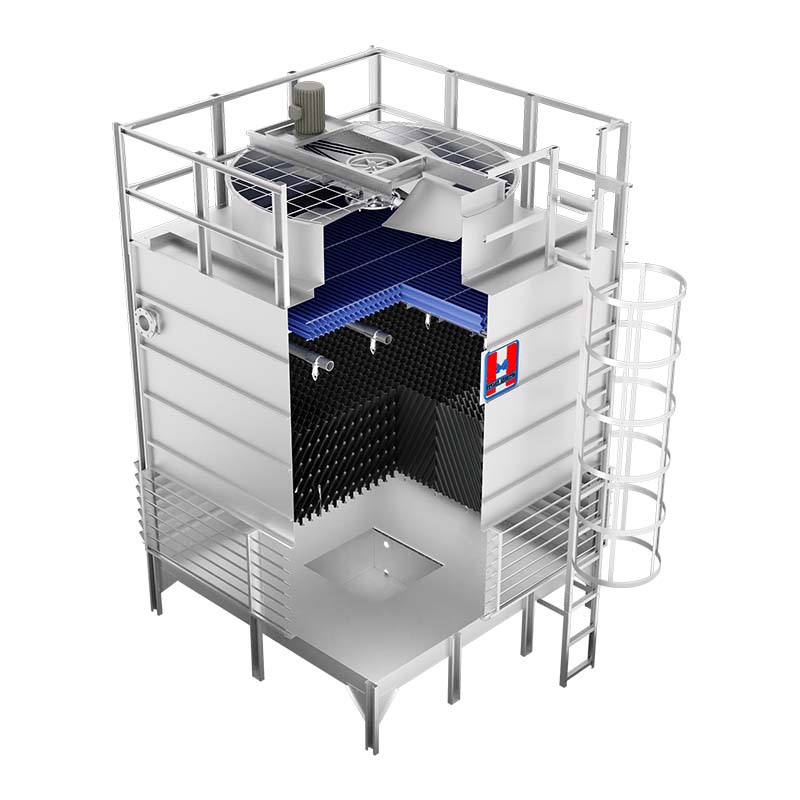

A mechanical draught cooling tower is a heat rejection device that uses mechanically driven fans to control airflow through the tower, improving cooling efficiency regardless of ambient wind conditions.

From a structural perspective, the tower typically consists of:

Load-bearing frame

External casing or panels

Basin and water collection system

Fan deck and fan stack

Internal support grids for fill and drift eliminators

Each of these components must be structurally coordinated.

Induced draft towers place the fan at the top, pulling air upward through the fill. Structurally, this design requires:

A reinforced fan deck

Strong fan stack support

Vibration-resistant framing

This configuration dominates modern industrial applications due to its efficiency and stable airflow pattern.

Forced draft towers locate the fan at the air inlet. Structural considerations include:

Reinforced inlet framing

Protection against air recirculation

Compact but rigid casing support

Although less common, forced draft designs are still used where space or layout constraints exist.

The frame acts as the skeleton of the cooling tower. It must support:

The full operating weight of water

Internal components such as fill and drift eliminators

Mechanical equipment loads

Common structural materials include FRP, galvanized steel, and stainless steel, selected based on corrosion risk and environmental conditions.

The basin is more than a water container—it is a critical structural element. It must:

Withstand continuous hydrostatic pressure

Maintain level alignment

Resist corrosion and leakage

Poor basin design often leads to uneven loading and long-term structural issues.

Air inlet louvers guide airflow into the tower while protecting internals from debris and sunlight. Structurally, they must resist wind pressure and maintain alignment over time.

Fill support structures carry significant loads, especially when fully wetted.

Includes the weight of fill, drift eliminators, and retained water.

Accounts for vibration, airflow turbulence, and thermal expansion.

A properly designed support grid prevents sagging, airflow imbalance, and localized stress.

The fan deck must remain rigid under dynamic loads. Even small deflections can reduce fan efficiency and increase mechanical wear.

Structural stiffness, isolation pads, and damping elements help:

Reduce transmitted vibration

Lower noise levels

Extend the life of motors and gearboxes

Mechanical draught cooling towers are often installed outdoors, exposed to:

High winds

Seismic activity

Snow, temperature fluctuation, and UV radiation

Structural design must comply with applicable codes to ensure stability under extreme conditions.

Common structural materials include:

FRP (Fiber Reinforced Plastic) – lightweight and corrosion-resistant

Galvanized steel – strong and economical

Stainless steel – ideal for aggressive chemical environments

Material choice directly affects durability and lifecycle cost.

Cooling towers operate in a harsh environment where moisture and chemicals are constant. Protective coatings, resin systems, and proper drainage design are essential to prevent long-term structural degradation.

Factory-controlled quality

Faster installation

Ideal for limited construction windows

Custom sizing and capacity

Suitable for large industrial projects

Require precise structural planning

Each approach has unique structural implications.

A well-designed structure considers not only operation but also people. Integrated walkways, ladders, guardrails, and access platforms ensure safe and efficient maintenance throughout the tower’s life.

Structural design is not just theoretical—it’s practical. Experienced manufacturers understand:

Real operating loads

Installation challenges

Long-term maintenance behavior

This experience transforms drawings into reliable, real-world structures.

Mach Cooling (https://www.machcooling.com/) combines engineering expertise with manufacturing capability to deliver mechanically robust cooling towers. Their approach focuses on:

Optimized structural design

Proper material selection

Compliance with international standards

Long service life in demanding industrial environments

Mechanical draught cooling towers with robust structural design are widely used in:

Power generation

HVAC and district cooling

Petrochemical and chemical plants

Steel and metallurgy

Data centers and manufacturing facilities

Each industry places unique demands on structural integrity.

The structural design of mechanical draught cooling towers is the foundation of reliable cooling performance. From frames and basins to fan decks and fill supports, every structural decision influences efficiency, safety, and longevity.

When engineered and manufactured by experienced companies like Mach Cooling, cooling towers don’t just stand still—they perform consistently, endure harsh conditions, and deliver long-term value.