We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-01-20 Origin: Site

When people talk about cooling towers, they usually focus on water, evaporation, or fill media. But in an induced cooling tower, there’s one component that quietly controls everything—the fan.

The fan is not just a moving part. It is the heart of airflow, the driver of evaporation, and the key to stable cooling performance. Without the right fan design, even the most advanced cooling tower cannot deliver its full potential.

So let’s take a closer look at the role of the fan in an induced cooling tower, explained in clear, practical terms.

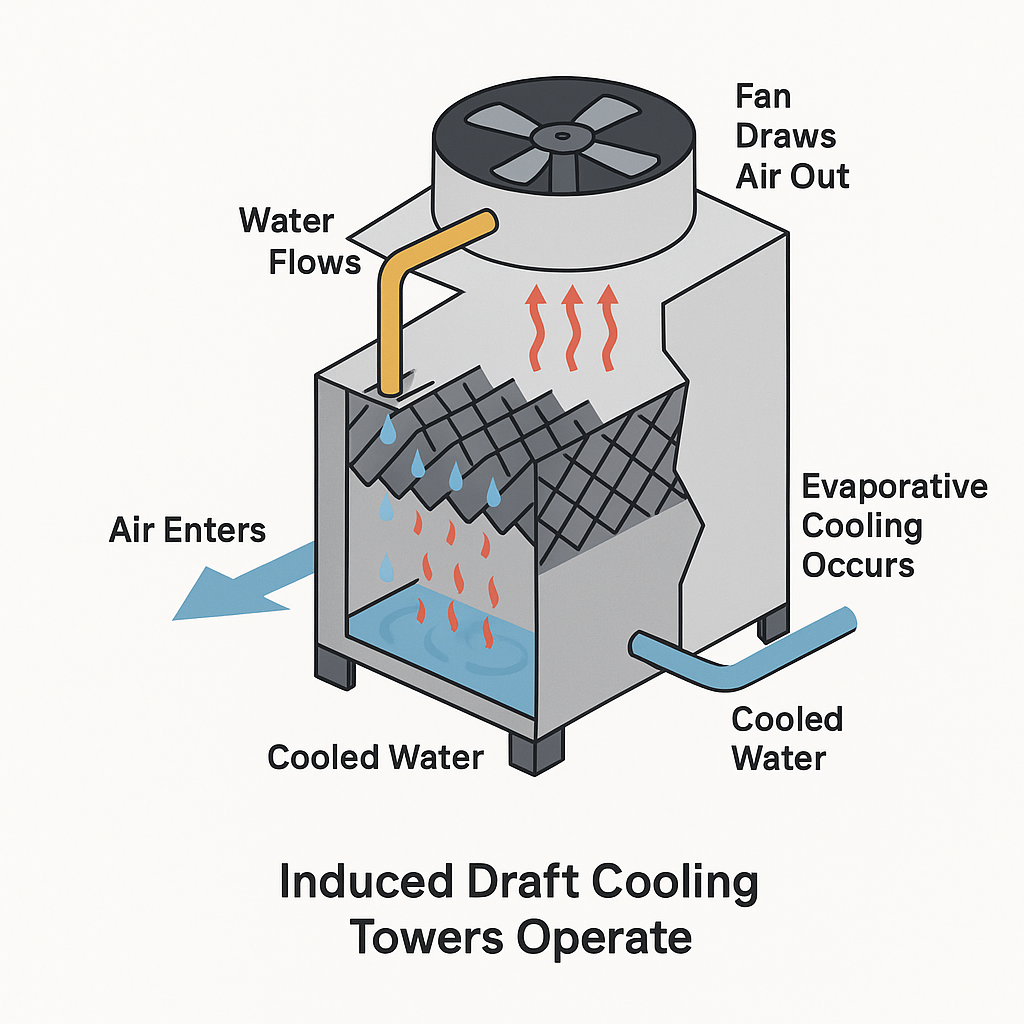

An induced cooling tower is a cooling tower design in which the fan is installed at the air discharge side, typically at the top of the tower. Instead of pushing air into the system, the fan pulls air upward through the fill and water distribution zones.

This induced airflow creates a stable negative pressure environment inside the tower, resulting in more uniform air distribution and higher cooling efficiency. That’s why induced cooling towers are the most widely used design in industrial and HVAC applications worldwide.

If a cooling tower were a living organism, the fan would be its lungs.

No airflow means no evaporation.

No evaporation means no heat rejection.

The fan directly determines:

How much air passes through the tower

How evenly air contacts the falling water

How efficiently heat is removed

How much electrical energy the system consumes

In short, the fan controls both performance and operating cost.

In an induced cooling tower, the fan creates a negative pressure zone inside the structure. This pressure difference draws fresh ambient air in through the air inlets and louvers, forces it across the fill media, and finally discharges warm, moist air at the top.

This upward airflow pattern is stable, predictable, and highly efficient.

Because the fan handles hot, saturated exhaust air instead of cool inlet air, it reduces the risk of air recirculation and improves performance under varying weather conditions.

Axial fans are the most common choice for induced cooling towers. They move large volumes of air at relatively low pressure and offer excellent energy efficiency. Their simple design also makes maintenance easier and more cost-effective.

Centrifugal fans are used in special cases where higher static pressure is required. While they are more powerful, they generally consume more energy and are less common in standard industrial cooling towers.

Evaporation is the core cooling mechanism in a wet cooling tower. The fan ensures continuous air movement, allowing warm water to release heat efficiently as a small portion evaporates.

Without adequate airflow, evaporation slows down, and cooling capacity drops immediately.

Uneven airflow leads to hot spots, poor fill utilization, and increased scaling. A properly designed fan system distributes air evenly across the entire fill area, maximizing heat transfer efficiency.

Airflow rate determines how much air moves through the tower per unit of time. Too little airflow reduces cooling; too much airflow wastes energy.

Static pressure represents the resistance the fan must overcome, including fill media, drift eliminators, and internal structure.

Higher fan efficiency means lower power consumption and reduced operating costs—especially critical for cooling towers that run 24/7.

Fans typically account for the largest share of a cooling tower’s energy use. That’s why modern induced cooling towers focus heavily on fan optimization.

Common optimization strategies include:

High-efficiency aerodynamic fan blades

Variable Frequency Drives (VFDs)

Optimized blade pitch and rotation speed

Manufacturers like Mach Cooling design fan systems as an integrated part of the cooling tower, ensuring airflow and energy efficiency are perfectly balanced.

Fan noise is a major concern, particularly in urban, commercial, or residential-adjacent installations.

Induced cooling tower fans help reduce noise by:

Operating at lower tip speeds

Using optimized blade profiles

Minimizing vibration through precise balancing

Good fan design doesn’t just cool efficiently—it does so quietly.

Even the best fan systems can develop issues if not properly maintained. Common problems include:

Blade erosion or fouling

Bearing wear

Motor overheating

Vibration caused by misalignment

Early detection and regular inspection prevent these issues from affecting overall cooling performance.

Routine fan maintenance delivers one of the highest returns on investment in cooling tower operation.

Key maintenance tasks include:

Inspecting and cleaning fan blades

Checking bearing lubrication

Monitoring vibration levels

Verifying motor alignment and electrical performance

Well-maintained fans ensure stable airflow and long service life.

Induced cooling tower fan systems are widely used in:

Power plants

Oil and gas facilities

Chemical and petrochemical plants

Large HVAC systems

Steel, cement, and manufacturing industries

In all these applications, fan reliability directly impacts system reliability.

Choosing the right cooling tower manufacturer means choosing the right fan system.

Mach Cooling (https://www.machcooling.com/) designs induced cooling towers with fan performance as a core engineering focus—not an afterthought.

Mach Cooling fan systems offer:

High aerodynamic efficiency

Durable materials for harsh environments

Stable airflow under fluctuating loads

Long service life with minimal maintenance

This attention to fan design ensures consistent cooling performance and reduced lifecycle costs.

The role of the fan in an induced cooling tower cannot be overstated.

The fan drives airflow, controls evaporation, determines energy efficiency, influences noise levels, and defines overall system reliability. Without a properly engineered fan, even the best cooling tower design will fall short.

By understanding the fan’s role—and partnering with experienced manufacturers like Mach Cooling—industries can achieve reliable, efficient, and long-lasting cooling performance.