We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-01-12 Origin: Site

Nuclear power plants are often seen as symbols of advanced engineering, but behind the massive reactor buildings and iconic cooling towers lies a carefully orchestrated system whose sole purpose is simple yet vital: heat removal. Without reliable cooling, nuclear energy cannot be produced safely or efficiently.

In this article, we’ll take a deep dive into the primary, secondary, and tertiary cooling systems in nuclear power plants, explaining how each system works, why multiple layers are essential, and how cooling towers—supported by experienced manufacturers like Mach Cooling—play a critical role in the final stage of heat rejection.

At its core, a nuclear power plant is a heat engine. Nuclear fission releases enormous amounts of thermal energy, and that heat must be continuously removed—during operation and even after shutdown.

To achieve this safely, nuclear plants rely on three independent cooling systems, each designed with strict isolation, redundancy, and safety margins.

Imagine driving a high-performance car without a radiator. It might run briefly, but failure is inevitable. Nuclear reactors are no different.

Cooling systems are responsible for:

Preventing fuel damage

Maintaining reactor stability

Producing electricity efficiently

Protecting people and the environment

Each cooling layer acts as a safeguard, ensuring that no single failure can lead to catastrophic consequences.

When uranium or other fissile materials split inside the reactor core, they release heat continuously. Even after a reactor is shut down, decay heat remains, making cooling indispensable at all times.

To manage this heat safely, nuclear plants use a multi-loop design:

The primary system removes heat from the reactor core

The secondary system converts heat into electricity

The tertiary system releases waste heat to the environment

Each loop transfers heat—not fluids—to the next.

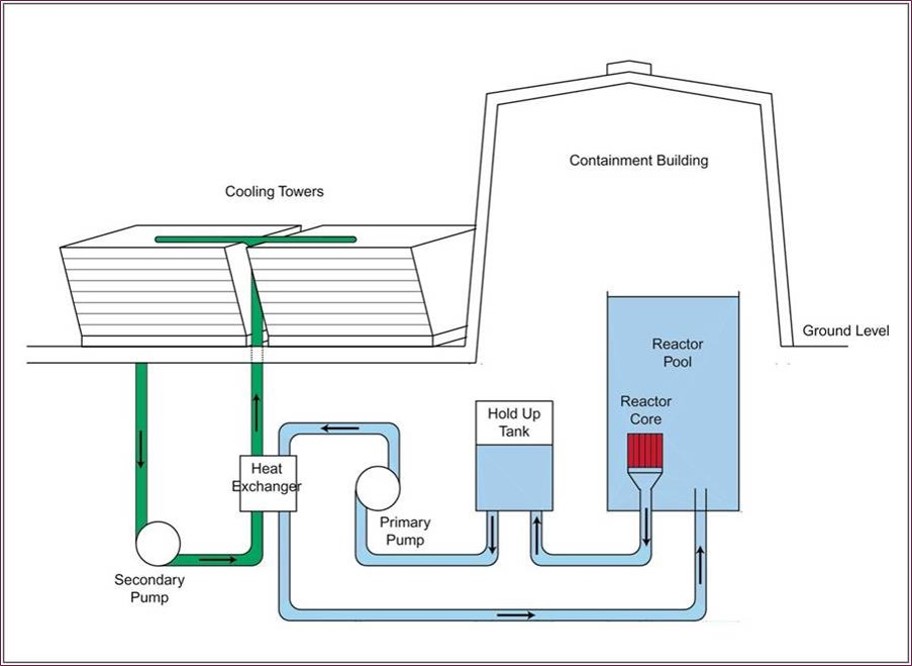

The primary cooling system is the closest system to the reactor core. Its job is to absorb heat directly from the nuclear fuel and transport it safely away while keeping radioactive materials fully contained.

In most reactors, highly pressurized water is used as coolant. It absorbs heat efficiently without boiling, even at extremely high temperatures.

Large, powerful pumps ensure continuous circulation of coolant, maintaining stable temperatures across the reactor core.

The primary system operates inside a sealed, reinforced containment structure. Its design priority is radioactive isolation, making it the most strictly regulated system in the entire plant.

The secondary cooling system receives heat from the primary loop via steam generators. Here, water is converted into steam that drives turbines to generate electricity.

Crucially, this system is non-radioactive under normal operation.

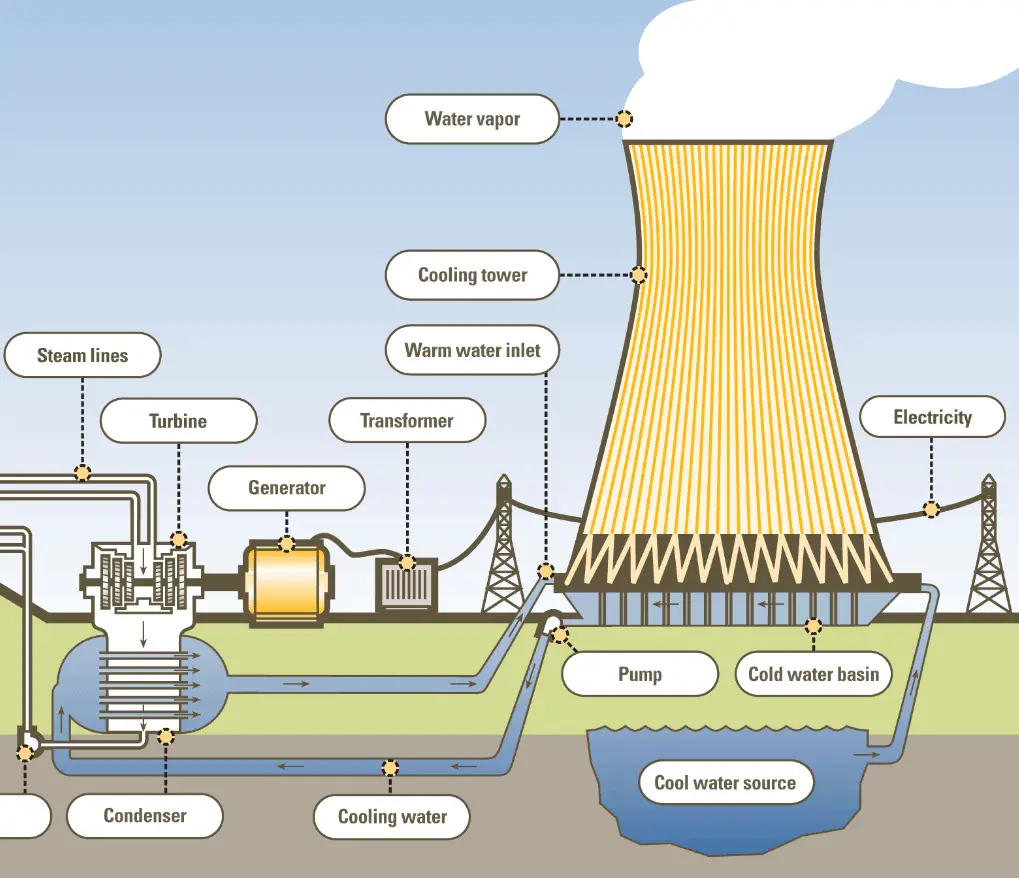

As steam expands through turbines, it spins generator shafts—transforming thermal energy into electrical energy. Afterward, the steam must be condensed and cooled again, which leads us to the third system.

Physical separation between these systems ensures that radioactive materials never come into contact with turbine equipment or the external environment, adding another layer of protection.

The tertiary cooling system removes excess heat from the secondary system after steam exits the turbine. It does not interact with radioactive materials and is designed for large-scale heat rejection.

This system typically relies on cooling towers to dissipate heat into the atmosphere.

These iconic hyperbolic towers use natural airflow and are commonly associated with nuclear power plants.

Fan-assisted towers offer precise airflow control and are used where site conditions require flexibility.

Think of the cooling process as a relay race:

The primary system carries heat from the reactor

The secondary system converts heat into power

The tertiary system safely releases unused heat

Each handoff is isolated, controlled, and continuously monitored.

Cooling towers are the final and visible stage of the cooling process. Their efficiency directly impacts plant output, water usage, and environmental performance.

Modern nuclear cooling systems are engineered to:

Reduce thermal pollution

Optimize water consumption

Prevent environmental contamination

Meet stringent international standards

Cooling tower performance plays a key role in achieving these objectives.

Routine inspections, predictive maintenance, and material upgrades are essential to ensure long-term reliability. Even small inefficiencies can lead to power reductions or forced shutdowns.

Cooling towers used in nuclear and power generation projects must meet exceptional standards for:

Structural integrity

Thermal efficiency

Long service life

This requires deep engineering expertise and proven manufacturing capability.

Mach Cooling (https://www.machcooling.com/) provides engineered cooling tower solutions for large-scale industrial and power generation applications. With experience in materials, airflow design, and thermal optimization, Mach Cooling supports reliable heat rejection systems that align with the demanding requirements of nuclear and energy projects.

The primary, secondary, and tertiary cooling systems in nuclear power plants form a carefully layered safety and efficiency framework. Each system has a clear role, strict separation, and built-in redundancy.

From the reactor core to the plume rising above a cooling tower, every component works together to ensure nuclear power remains a safe, stable, and sustainable energy source—supported by well-designed cooling infrastructure and experienced manufacturers like Mach Cooling.