We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-01-09 Origin: Site

Cooling towers play a critical role in industrial and HVAC systems, quietly removing heat and keeping operations running smoothly. Yet many operators overlook one of the most powerful tools for maximizing cooling tower efficiency—chemical water treatment.

Think of chemical water treatment as preventative healthcare for your cooling tower. When done right, it keeps the system clean, efficient, and reliable. When ignored, performance drops, costs rise, and equipment lifespan shortens. In this article, we’ll explore how chemical water treatment optimizes cooling tower performance and why manufacturers like Mach Cooling consider it essential to long-term system success.

Cooling tower performance directly impacts operational efficiency. Poor performance doesn’t just mean weaker cooling—it leads to:

Higher energy consumption

Increased water usage

More frequent maintenance

Unexpected shutdowns

In industrial environments, these issues quickly translate into lost productivity and higher operating costs. Optimizing cooling tower performance is not optional—it’s a strategic necessity.

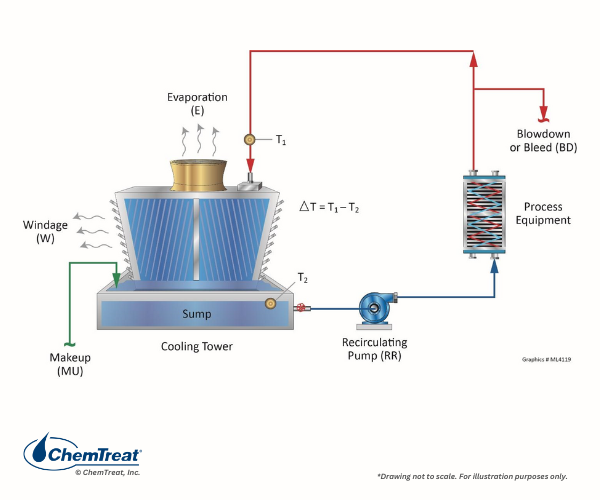

Chemical water treatment involves adding carefully selected chemicals to cooling tower water to control scale, corrosion, and biological growth. Because cooling towers operate by evaporating water, dissolved minerals and impurities concentrate over time. Without treatment, this concentration becomes destructive.

As water evaporates, minerals stay behind. The higher the concentration, the greater the risk of scale, corrosion, and microbial growth. Chemical water treatment keeps this chemistry balanced and predictable.

Scale forms when calcium and magnesium precipitate out of water and stick to heat transfer surfaces. Even a thin layer acts like insulation, reducing heat transfer efficiency and forcing equipment to work harder.

Corrosion attacks metal components such as basins, pipes, and heat exchangers. Once corrosion begins, it spreads quickly—leading to leaks, structural damage, and premature equipment failure.

Warm, oxygen-rich water is ideal for bacteria and algae. Biofouling restricts water flow, reduces efficiency, and can create serious health risks if not controlled.

Scale inhibitors prevent minerals from crystallizing and bonding to surfaces. Instead, they remain suspended in the water and are safely discharged through controlled blowdown.

These chemicals form a microscopic protective layer on metal surfaces, shielding them from aggressive water chemistry and oxygen attack.

Biocides eliminate microorganisms, while dispersants prevent dead biological matter from accumulating and forming slime.

Clean heat exchange surfaces allow heat to move quickly and efficiently. Chemical water treatment ensures nothing blocks this transfer—no scale, no biofilm, no corrosion.

When heat transfer improves, fans and pumps don’t have to work as hard. This reduces electricity usage and cuts operating costs.

A well-treated cooling tower ages slowly. Chemical protection minimizes wear and corrosion, allowing equipment to operate reliably for many more years.

Maintaining the correct balance prevents both scaling and corrosion. Conductivity monitoring helps control blowdown and water usage.

Regular testing ensures biocides are effective and biological growth remains under control.

Manual dosing relies on operator experience and frequent testing. Automatic dosing systems provide consistency and accuracy, especially in large or critical installations.

Modern systems adjust chemical feed rates in real time based on water quality data, optimizing chemical usage and system protection.

From a manufacturer’s point of view, cooling tower performance goes far beyond mechanical design. At Mach Cooling, chemical water treatment is viewed as an extension of engineering.

Even the most advanced cooling tower will underperform without proper water chemistry management. That’s why Mach Cooling designs systems that integrate seamlessly with modern water treatment programs.

Today’s chemical water treatment solutions focus on sustainability. Advanced formulations reduce chemical consumption, minimize blowdown, and conserve water—helping facilities meet environmental goals without sacrificing performance.

Many performance issues stem from avoidable mistakes, such as:

Overdosing chemicals “just in case”

Ignoring seasonal changes in water quality

Skipping system cleaning before treatment

Using generic chemical programs for all systems

Avoiding these errors leads to immediate performance improvements.

Perform regular water analysis

Maintain proper blowdown control

Use automated chemical dosing

Inspect mechanical components routinely

Work with experienced manufacturers and service partners

Cooling tower optimization starts with smart equipment selection. Partnering with a reliable manufacturer like Mach Cooling (https://www.machcooling.com/) ensures your cooling tower is designed for efficiency, durability, and compatibility with modern chemical water treatment solutions.

Optimizing cooling tower performance isn’t complicated—but it does require consistency and knowledge. Chemical water treatment keeps water chemistry stable, protects equipment, and maximizes efficiency.

When combined with high-quality cooling tower design and manufacturing expertise, chemical water treatment turns your cooling system into a reliable, cost-effective asset. Smarter water treatment means better cooling—and better business outcomes.