We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-01-12 Origin: Site

Cooling towers may look simple from the outside, but inside, they operate like a finely tuned ecosystem. Every internal component plays a specific role, and when one part underperforms, the entire system feels the impact. Among all components, Marley cooling tower fill, drift eliminator, and nozzle parts are the real workhorses behind cooling efficiency, water conservation, and long-term operational stability.

In this article, we’ll break down how these three core components function, why they matter so much, common problems they face, and how reliable manufacturers like Mach Cooling provide high-quality, Marley-compatible solutions for industrial users worldwide.

When people think about cooling towers, they usually focus on fans, motors, or gearboxes. But here’s the truth: those parts move air, while fill, drift eliminators, and nozzles actually make cooling happen.

These internal components determine:

How efficiently heat is transferred

How evenly water is distributed

How much water is lost through drift

How stable the tower operates over time

Ignoring them is like upgrading a car’s engine while leaving worn-out tires in place.

Imagine taking a shower under a broken showerhead. Some areas get soaked, others stay dry. That’s exactly what happens in a cooling tower when nozzles clog or fill degrades.

Poor internal components lead to:

Higher outlet water temperatures

Increased energy consumption

Excessive water loss

Scaling, fouling, and biological growth

On the flip side, optimized internals quietly improve performance every single hour the tower runs.

Before diving deeper, let’s clarify the roles of the three key components:

Maximizes contact between air and water for effective heat transfer.

Capture water droplets before they escape with exhaust air.

Distribute hot water evenly across the fill surface.

These parts must work together. If one fails, the entire cooling process suffers.

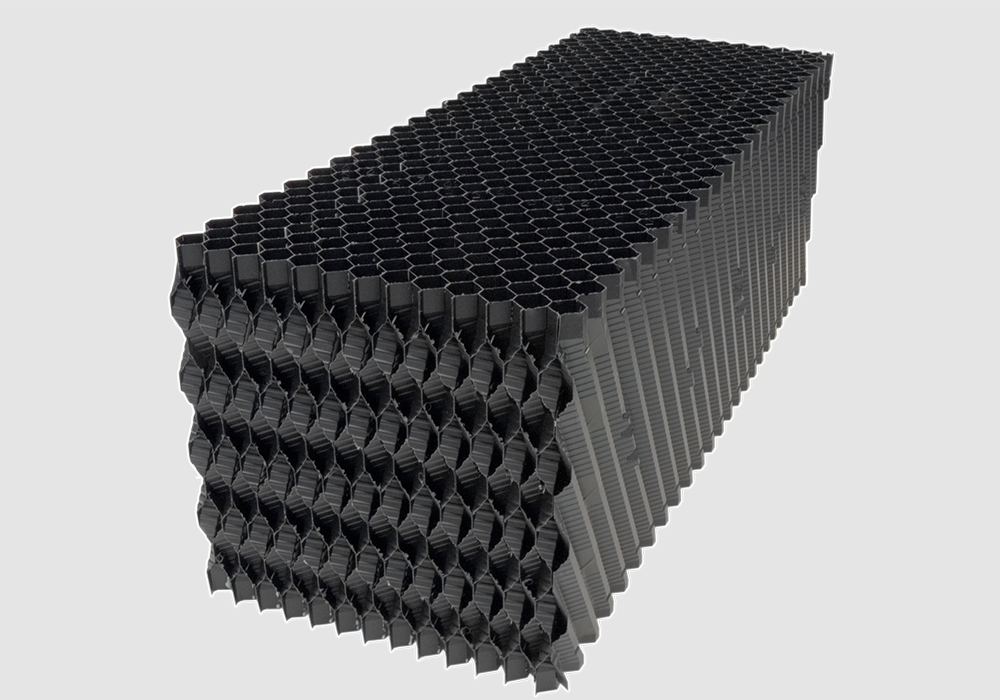

Cooling tower fill is designed to increase surface area and contact time between air and water. The greater the contact, the more evaporation occurs—and evaporation is what removes heat.

In simple terms:

Better fill = better cooling.

Film fill spreads water into thin sheets flowing over closely spaced surfaces.

Key advantages:

High thermal efficiency

Compact design

Ideal for clean or well-treated water systems

This type is commonly used in HVAC and power plant cooling towers.

Splash fill breaks water into droplets as it falls through structural elements.

Key advantages:

Excellent resistance to clogging

Performs well with dirty or high-solids water

Longer service life in harsh environments

Industries such as steel, mining, and petrochemicals often prefer splash fill.

Most Marley-compatible cooling tower fill is made from:

PVC – cost-effective, excellent heat transfer

PP (Polypropylene) – higher temperature and chemical resistance

Manufacturers like Mach Cooling select materials based on water quality, operating temperature, and airflow design to ensure long-term reliability.

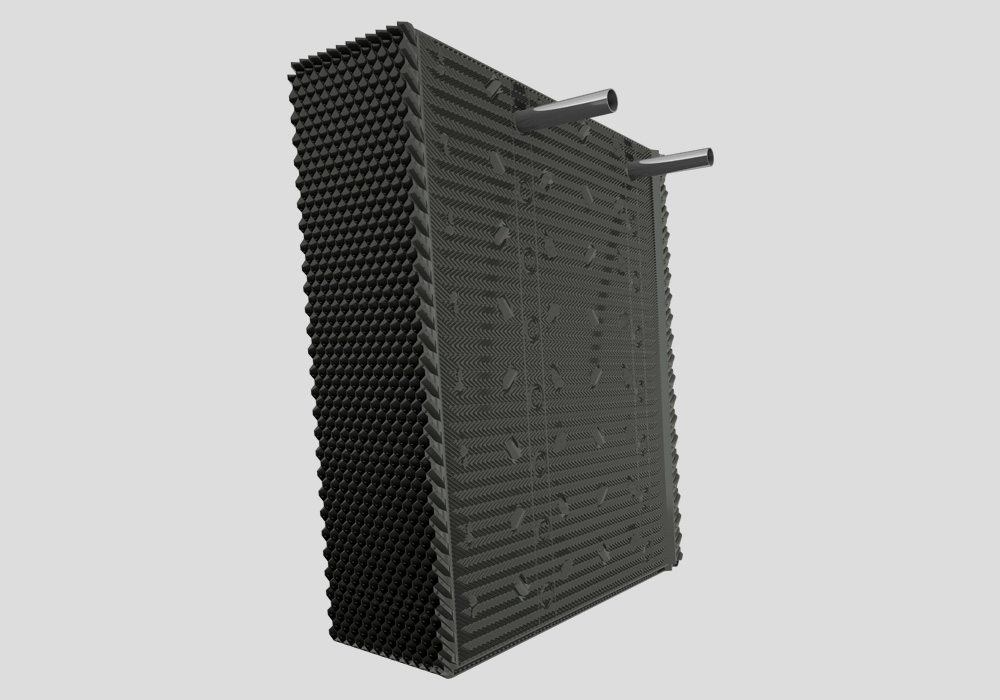

Drift eliminators prevent water droplets from escaping the cooling tower with exhaust air. Without them, valuable treated water is lost—and surrounding equipment, structures, or walkways may suffer corrosion or scaling.

Common Marley-compatible designs include:

Cellular drift eliminators

Blade-type drift eliminators

High-efficiency multi-pass configurations

High-quality designs can reduce drift loss to below 0.001% of circulating water flow.

Environmental regulations around the world are becoming stricter. Efficient drift eliminators help facilities:

Reduce water consumption

Prevent chemical mist emissions

Meet environmental and workplace safety standards

In short, drift eliminators protect both the system and its surroundings.

Spray nozzles control how evenly hot water is distributed over the fill. Uneven distribution leads to dry spots, scaling, and reduced heat transfer.

A good nozzle system ensures:

Uniform wetting of fill

Stable cooling performance

Lower maintenance frequency

Simple structure

Reliable operation

Commonly used in crossflow towers

Large orifice design

Suitable for poor water quality

Ideal for industrial and recycled water systems

Choosing the right nozzle design makes a noticeable difference in long-term performance.

Think of these components as a team:

Nozzles distribute water evenly

Fill maximizes heat transfer

Drift eliminators recover escaping droplets

When all three are properly designed and matched, cooling efficiency improves while operating costs drop.

Internal component issues often show subtle symptoms:

Rising cold-water temperature

Visible mist drifting from the tower

Uneven wetting or dry zones in the fill

Increasing makeup water usage

These problems usually point to aging fill, clogged nozzles, or damaged drift eliminators.

Best-performing cooling towers follow a proactive approach:

Inspect fill annually

Clean or replace nozzles during shutdowns

Replace drift eliminators when efficiency declines

Preventive maintenance is always cheaper than emergency repairs.

OEM parts are reliable, but they can be expensive and slow to deliver. High-quality compatible parts offer a smart alternative.

Professional manufacturers like Mach Cooling provide:

Precise dimensional compatibility

Equivalent or improved materials

Faster lead times

Competitive pricing

Compatibility is about engineering accuracy—not just copying shapes.

Mach Cooling (https://www.machcooling.com/) specializes in Marley-compatible cooling tower parts, including:

Cooling tower fill

Drift eliminators

Water distribution nozzles

With strong manufacturing capabilities, strict quality control, and global export experience, Mach Cooling helps customers restore cooling tower performance with confidence.

These components are widely applied in:

Power generation

HVAC and district cooling

Petrochemical and chemical plants

Steel and metallurgy

Data centers and industrial facilities

Each application requires customized internal solutions.

While high-quality internals may require higher initial investment, they deliver:

Lower fan energy consumption

Reduced water loss

Longer service life

Over time, performance-driven components always provide better return on investment.

Cooling towers don’t fail overnight. They lose efficiency gradually—through worn fill, inefficient drift eliminators, and clogged nozzles. Upgrading Marley cooling tower fill, drift eliminator, and nozzle parts is one of the most effective ways to restore performance and control operating costs.

With experienced manufacturers like Mach Cooling, replacing parts isn’t just maintenance—it’s a strategic upgrade.