We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-12-09 Origin: Site

A water cooling tower is a critical component of any industrial, HVAC, or power plant system. It removes heat from circulating water and improves the efficiency of the water cooling tower system. Building a cooling tower involves engineering principles in thermodynamics, fluid mechanics, and structural design. This article guides you through the process of making a cooling tower, from design to assembly, emphasizing reliability and efficiency.

As a leading manufacturer, MACH Cooling (https://www.machcooling.com/) provides professional solutions and technical support for building efficient cooling towers.

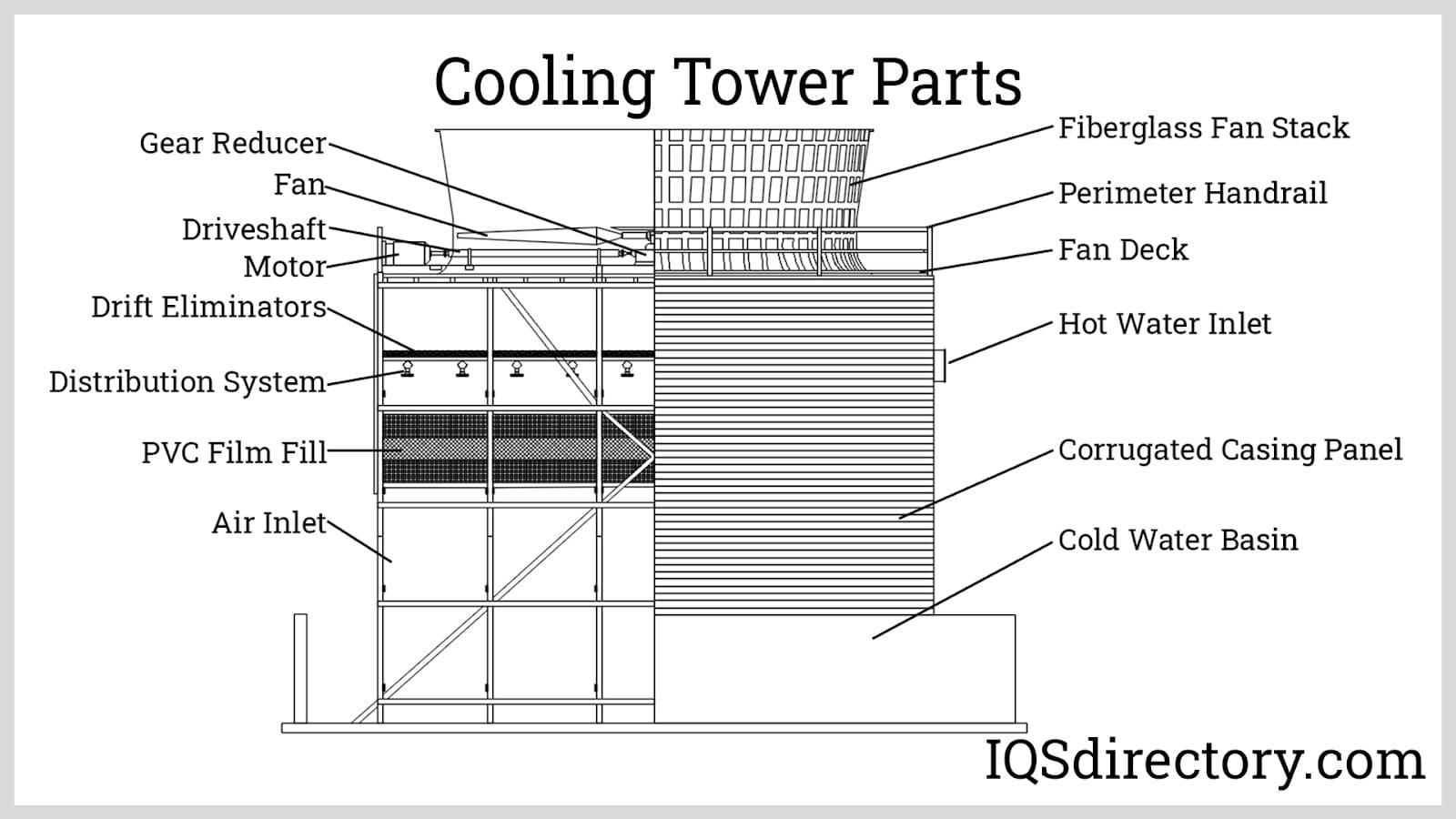

Before constructing a cooling tower, it’s important to understand the water cooling tower system and its core components.

Water distribution system: Sprays warm water evenly over the fill.

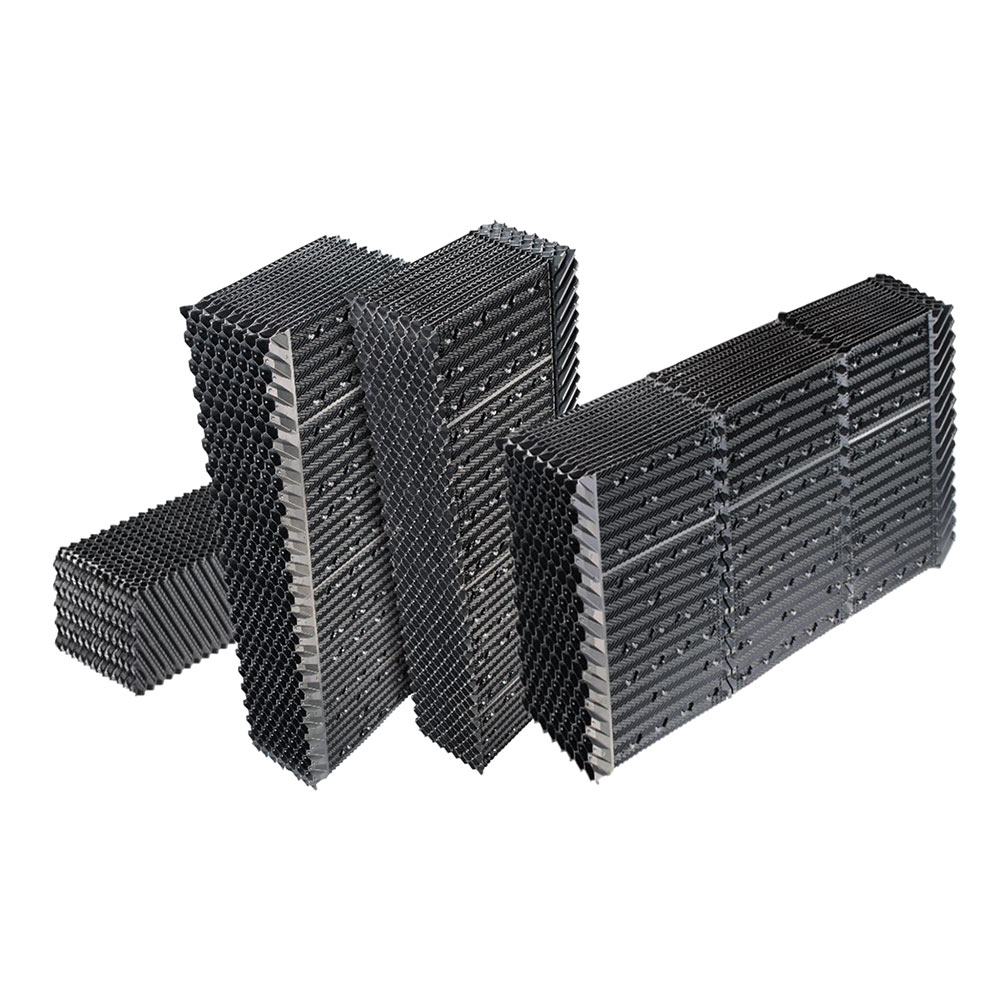

Fill media: Increases surface area for heat transfer.

Fan: Enhances airflow through the fill.

Drift eliminator: Reduces water loss from drift.

Cold water basin: Collects cooled water.

Structure: Supports the tower and houses all components.

| Component | Function | Notes |

|---|---|---|

| Fill media | Maximizes heat exchange | Must be resistant to scaling and biofouling |

| Fan | Drives airflow | FRP or aluminum blades recommended |

| Drift eliminator | Minimizes water loss | Reduces environmental impact |

| Cold water basin | Stores cooled water | Corrosion-resistant material preferred |

| Structure | Supports tower components | FRP, galvanized steel, or stainless steel |

The first step is to calculate the required heat removal for your water cooling tower system.

Cooling load is measured in kW, kcal/hr, or RT.

Consider inlet water temperature, outlet water temperature, and ambient wet bulb temperature.

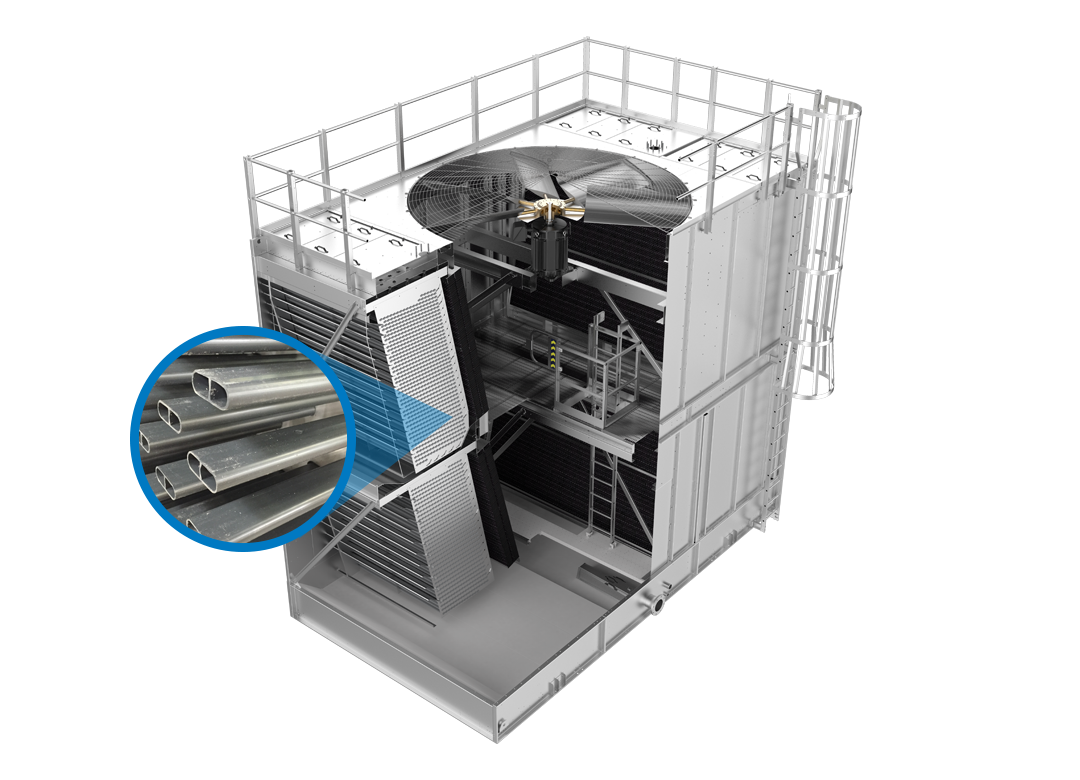

Cross-flow tower: Water flows horizontally, air flows vertically.

Counter-flow tower: Water and air move in opposite directions.

Closed-circuit tower: Water remains inside tubing, suitable for sensitive fluids.

MACH Cooling provides both cross-flow and counter-flow towers with modular designs, customizable for different industrial applications.

FRP (Fiberglass Reinforced Plastic) for lightweight corrosion-resistant towers

HDG galvanized steel for heavy-duty applications

Stainless steel (SS304/SS316) for chemical-resistant environments

PVC high-efficiency fill: 125–250 m²/m³, ideal for most industrial applications

PP splash fill: 90–120 m²/m³, suitable for dusty water conditions

| Fill Type | Surface Area (m²/m³) | Advantages | Application |

|---|---|---|---|

| PVC Film Fill | 125–250 | High heat transfer, low cost | General industrial |

| PP Splash Fill | 90–120 | Resistant to clogging | Dusty environments |

| High-Efficiency Film Fill | 150–250 | Maximum cooling efficiency | HVAC systems |

Install base frame and cold water basin

Ensure foundation is level and can support full water load

Assemble tower walls and structural framework

Place the fill securely in the designed slots

Ensure uniform water distribution over the fill

Check for proper spacing to avoid airflow blockage

Mount the fan on the motor shaft

Ensure alignment and balance (G6.3/G2.5 dynamic balance)

Install drift eliminators and louvers

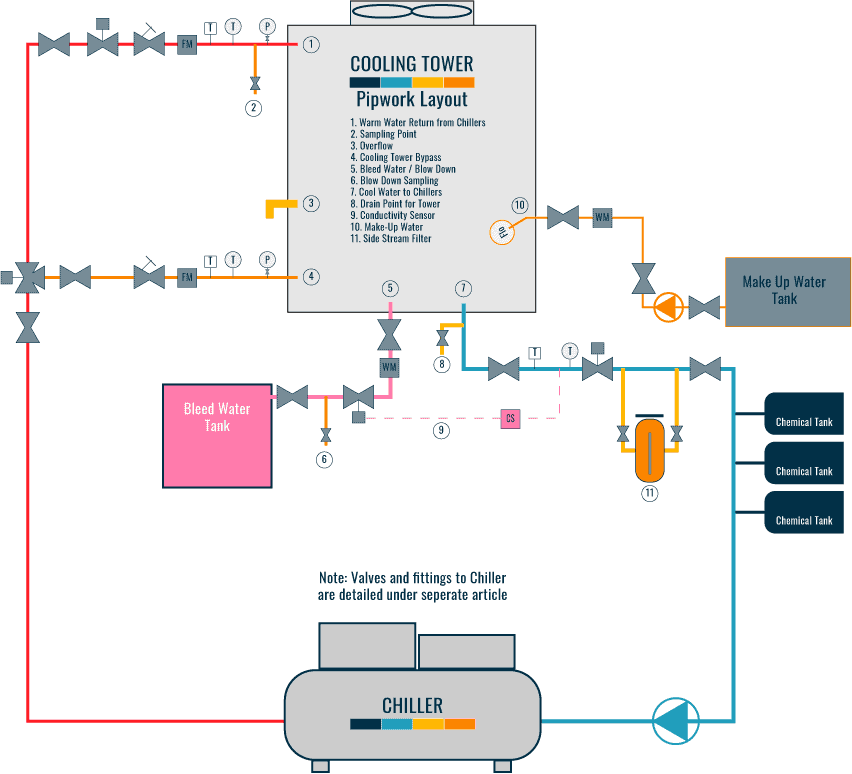

Connect the water piping and distribution nozzles

Lockout power systems during installation

Use proper lifting equipment for heavy components

Ensure structural components are securely fastened

Verify pump capacity matches cooling load

Check mechanical seals and bearings

Test for leaks before starting

Connect tower to existing water circulation system

Test water flow, pressure, and distribution uniformity

Install water treatment equipment to prevent scale and algae

Fill the tower with water

Start fans and circulation pumps

Monitor inlet and outlet water temperatures

Ensure cold water meets design temperature

Check for vibration or unusual noise from fans

Verify no leaks or water overflow

Adjust fan speed if using VFD

Verify water distribution over the fill

Inspect drift eliminators and louvers for proper operation

As a professional manufacturer, MACH Cooling (https://www.machcooling.com/) provides:

Customized water cooling tower system design

High-quality components and materials

Installation guidance and on-site support

Commissioning and performance optimization

Global technical and after-sales service

Making a water cooling tower involves careful planning, material selection, structural assembly, and integration into the water cooling tower system. Proper design, assembly, and testing ensure efficient heat dissipation, energy savings, and long-term reliability.

By using MACH Cooling’s expertise and high-quality components, users can build a durable, high-performance cooling tower system tailored to industrial, commercial, and HVAC applications.