We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-12-09 Origin: Site

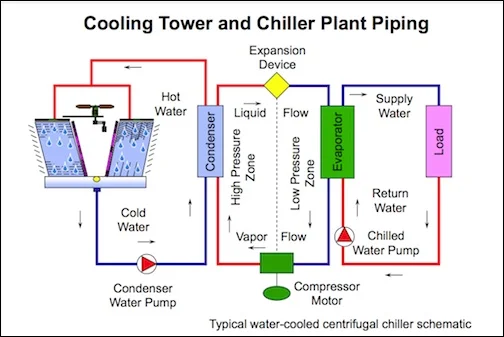

Designing a cooling tower is a comprehensive engineering process that integrates aerodynamics, heat transfer, hydrodynamics, materials science, and structural mechanics. Whether for industrial applications, HVAC systems, or large-scale power generation, a well-designed cooling tower significantly improves heat dissipation efficiency, reduces energy consumption, and minimizes long-term maintenance costs.

As a professional cooling tower manufacturer, MACH Cooling (https://www.machcooling.com/) provides a complete set of practical design principles applicable to various industries. This article explains how to design a cooling tower step-by-step.

Before the design stage, several key parameters must be defined. These inputs directly determine the size, structure type, and performance requirements of the cooling tower.

The cooling load is the most important factor in determining the capacity of a cooling tower, typically expressed in kcal/hr, kW, or RT (refrigeration tons).

Heat generated by process equipment

HVAC chilled water system capacity

Required temperature difference between hot and cold water

Local operating environment (temperature, humidity, altitude)

| Parameter | Definition | Importance |

|---|---|---|

| Hot Water Temperature | Temperature of water entering the tower | Determines required cooling duty |

| Cold Water Temperature | Temperature after cooling | Key measure of tower performance |

| Wet Bulb Temperature (WBT) | Ambient humidity-based temperature | Indicates theoretical cooling limit |

Water flow determines the filling volume, heat transfer area, fan capacity, and nozzle configuration.

Choosing the right cooling tower structure is the first design decision.

Cross-flow cooling tower

Counter-flow cooling tower

Closed-circuit cooling tower

Hyperbolic natural draft tower

For industrial and HVAC applications, MACH Cooling offers high-efficiency cross-flow and counter-flow cooling towers with optional FRP or metal-structure designs.

The fill (packing) is the core component of a cooling tower.

Specific surface area (m²/m³)

Material (PVC, PP)

Corrugated geometry and water distribution uniformity

Anti-blocking and anti-aging performance

| Fill Type | Specific Surface Area | Application | Features |

|---|---|---|---|

| PVC Film Fill | 125–250 m²/m³ | General industrial | High heat exchange, cost-effective |

| PP Splash Fill | 90–120 m²/m³ | Dusty environments | High temperature resistance, clog-resistant |

| High-efficiency film fill | 150–250 m²/m³ | HVAC | Higher cooling efficiency |

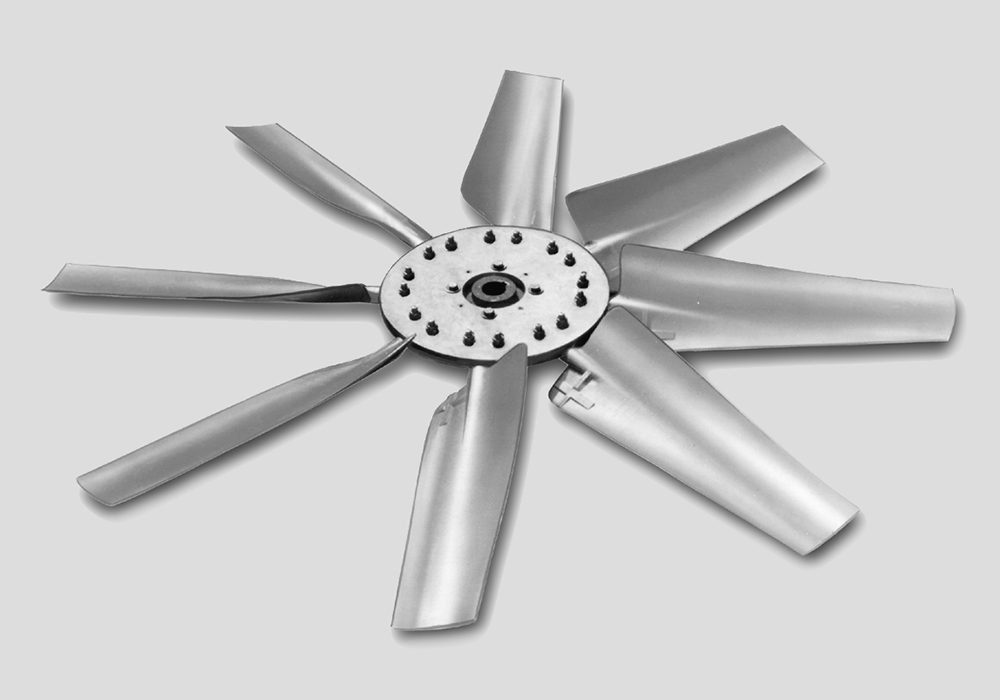

Airflow determines evaporation rate and heat rejection performance.

Fan diameter

Rotational speed (RPM)

Blade count and material (FRP, aluminum alloy)

Variable frequency drive (VFD) for energy efficiency

High-strength FRP blades

G6.3/G2.5 dynamic balance

Low noise aerodynamic profile

The structure must provide long-term durability and safety.

FRP (fiberglass reinforced plastic)

Galvanized steel

Stainless steel (SS304 / SS316)

HDG hot-dip galvanized frames

FRP round cooling towers

FRP square cooling towers

Metal counter-flow towers

Heavy-duty industrial cooling towers

Proper water distribution ensures effective wetting of fill and optimized cooling.

Gravity-type distribution basin (cross-flow)

Rotating sprinkler (counter-flow)

Pressurized nozzles (closed-circuit)

Key calculations include:

Overall heat transfer coefficient (KaV/L)

Required packing height

Approach to wet bulb temperature

Large-diameter low-speed fans

VFD energy-saving system

Low-noise blades

Acoustic barriers (if necessary)

Low drift water loss

Reduced air leakage

High-efficiency motors (IE3/IE4)

High-performance fill for water saving

As a professional manufacturer, MACH Cooling (https://www.machcooling.com/) provides complete engineering support:

On-site data collection and system evaluation

Thermal and structural calculation

CAD / 3D cooling tower design

Customized materials and configurations

Factory performance testing

Global shipping and installation guidance

Designing a high-performance cooling tower requires comprehensive evaluation of heat transfer, hydraulic systems, structural strength, noise control, and environmental adaptability. Through scientific design and accurate calculations, the cooling tower can operate efficiently, reduce energy consumption, and extend service life.

With MACH Cooling’s professional engineering capability, users can obtain high-efficiency, reliable, and customized cooling tower solutions.