We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-01-15 Origin: Site

Choosing the right cooling tower for air conditioning systems is far more than a routine equipment decision. It directly affects system efficiency, operating costs, reliability, and even the lifespan of your entire HVAC installation. If your chiller is the “heart” of the air conditioning system, then the cooling tower is its “lungs”—responsible for releasing heat and keeping everything running smoothly.

So how do you choose the right one? Let’s walk through the process step by step, in a clear, practical, and human way.

Before comparing models or prices, it’s essential to understand what a cooling tower actually does in an air conditioning system.

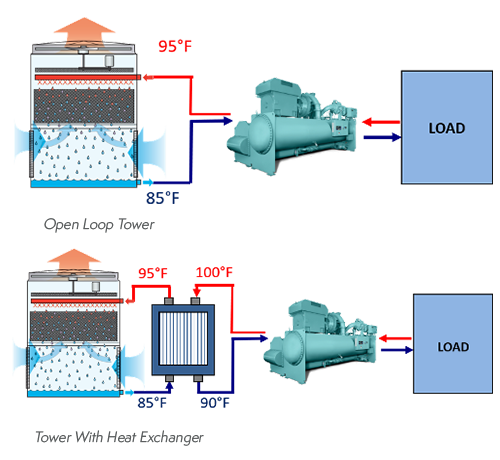

In water-cooled air conditioning systems, chillers absorb heat from indoor spaces. That heat must be rejected somewhere—and that’s where the cooling tower comes in. Through evaporative cooling, the tower transfers heat from water to the atmosphere, allowing the chilled water system to operate efficiently.

Without a properly selected cooling tower, even the most advanced chiller will struggle to reach its design performance.

Air-cooled systems rely solely on ambient air temperature, which limits efficiency in hot climates and large-scale applications. Cooling tower air conditioning systems, on the other hand, use water evaporation, offering higher efficiency, lower energy consumption, and better performance for commercial and industrial buildings.

Not all cooling towers serve the same purpose. Understanding the main types helps you make a smarter selection.

Open circuit cooling towers expose circulating water directly to air. They are widely used in HVAC systems due to their high efficiency and relatively low initial cost. With proper water treatment, they provide reliable long-term performance.

Closed circuit cooling towers keep the process water sealed inside coils, protecting it from contamination. These systems are ideal when water quality is critical or when maintenance needs to be minimized.

Hybrid cooling towers combine wet and dry cooling modes. They reduce water consumption and visible plume, making them suitable for urban projects or environmentally regulated locations.

This is where smart decisions really matter.

Cooling tower selection must be based on total heat rejection, not just cooling load. An undersized tower leads to poor performance, while an oversized one increases capital and operating costs. Accurate thermal calculations are essential.

Local wet-bulb temperature has a direct impact on cooling tower performance. Experienced manufacturers like MACH Cooling design cooling towers specifically matched to regional climate conditions, ensuring stable operation year-round.

Poor water quality causes scaling, corrosion, and biological growth. Selecting corrosion-resistant materials and planning a proper water treatment strategy from the beginning can dramatically extend equipment life.

A cooling tower is a long-term energy consumer, so efficiency matters.

High-efficiency axial fans and IE3 or IE4 motors reduce power consumption without sacrificing airflow. Over time, energy savings can be substantial.

VFDs allow fan speed to adjust based on real-time cooling demand. Instead of running at full power all day, the system operates intelligently—saving energy and reducing wear.

Real-world projects often come with space limitations.

Rooftop installations or retrofit projects may require compact or modular cooling tower designs. MACH Cooling offers customized solutions to fit tight mechanical spaces without compromising performance.

Noise control is critical for hospitals, hotels, and office buildings. Low-noise fans, vibration isolators, and acoustic solutions help meet strict environmental requirements.

Cooling towers operate outdoors and must endure harsh conditions.

FRP, galvanized steel, and stainless steel are selected based on environmental conditions, corrosion risk, and project requirements. The right material choice ensures durability and long service life.

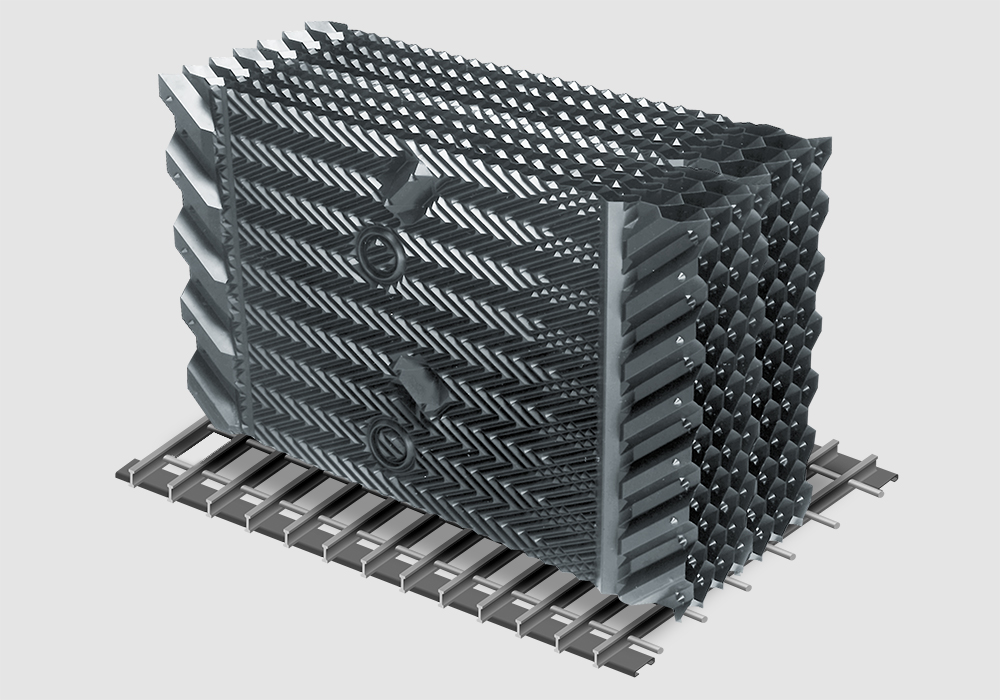

High-quality fill media maximizes heat transfer efficiency, while advanced drift eliminators minimize water loss and environmental impact—two small components with big influence.

A well-designed cooling tower should simplify, not complicate, maintenance.

Large access doors, modular components, and smart internal layouts reduce downtime and improve safety during inspections and cleaning.

Standardized components and readily available spare parts ensure quick repairs and lower lifecycle costs.

Two cooling towers may look similar on paper, but manufacturer expertise makes the difference. A professional supplier provides system design, thermal calculations, customization, and long-term technical support—not just equipment.

Choosing based on price alone

Ignoring water treatment requirements

Incorrect sizing

Overlooking noise regulations

Working with inexperienced suppliers

Avoiding these mistakes can save years of operational trouble.

MACH Cooling is a professional cooling tower manufacturer specializing in air conditioning applications. The company offers customized, energy-efficient, and durable cooling tower solutions backed by engineering expertise and international project experience.

Learn more at https://www.machcooling.com/.

Choosing the right cooling tower for air conditioning systems is about balance—performance, efficiency, durability, and long-term support. Make the right decision today, and your HVAC system will operate reliably, efficiently, and cost-effectively for decades.

A smart cooling tower investment now means fewer problems, lower energy bills, and peace of mind in the future.