We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-11-17 Origin: Site

In industrial operations, equipment such as compressors, chillers, and heat exchangers continuously generates heat. This excess heat must be effectively removed to ensure stable equipment performance, prolong service life, and reduce energy consumption. The cooling tower is a key device that solves this problem. By allowing circulating water to interact with air through evaporation and sensible heat transfer, the cooling tower releases heat into the atmosphere.

This article explains in detail the operating principles of industrial cooling towers, focusing on how water circulation achieves high-efficiency heat dissipation. It also highlights the technical strengths of Mach Cooling (https://www.machcooling.com/) in providing high-performance cooling solutions.

The core working mechanism of a cooling tower is evaporative cooling. When hot water is distributed over fill media and comes into contact with air, a small portion of the water evaporates. During this process, water molecules absorb a large amount of latent heat, thereby cooling the remaining water.

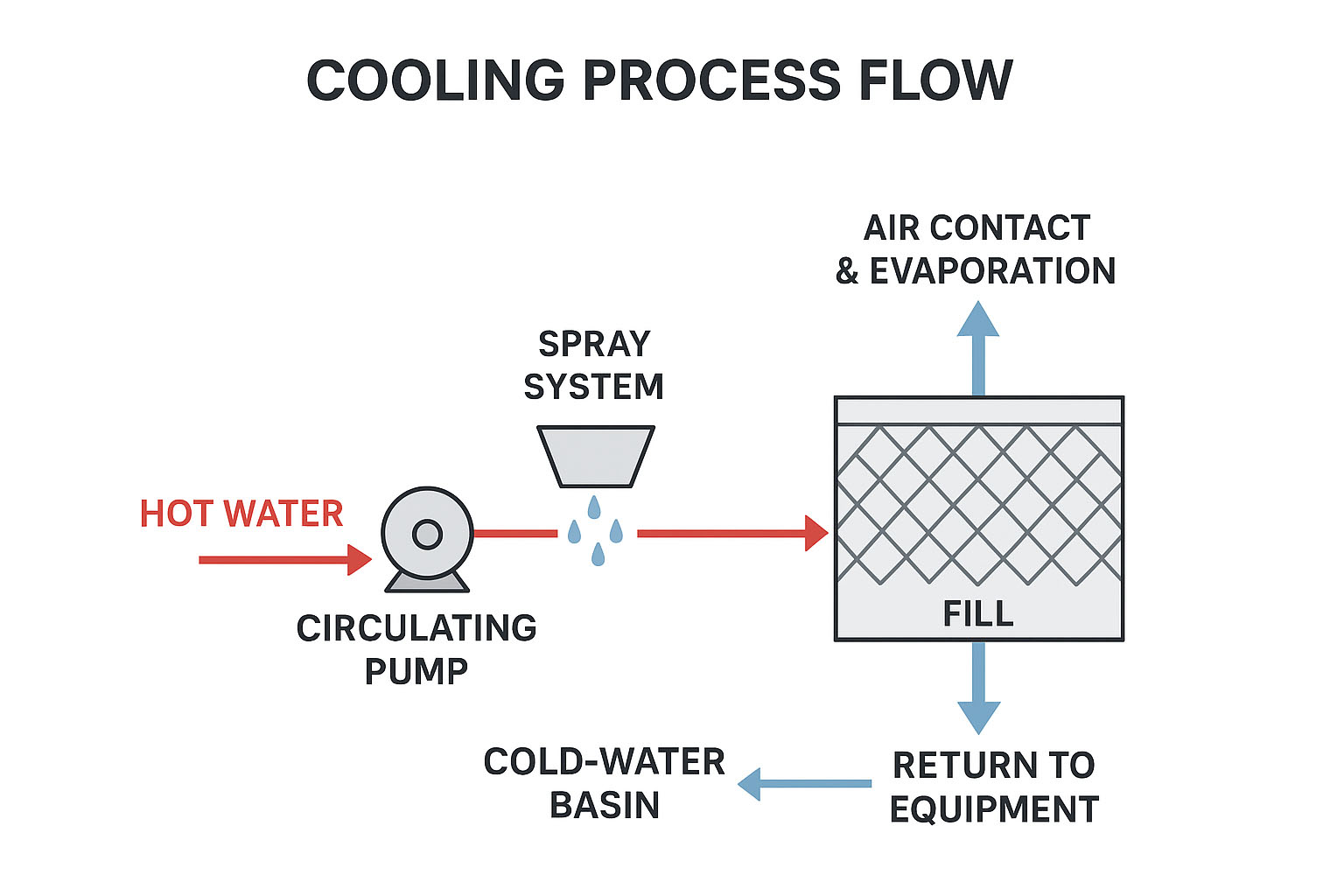

The process includes:

Hot water inlet: Heated water from industrial equipment is pumped to the top of the cooling tower.

Water distribution: Spray nozzles distribute hot water evenly onto the fill.

Air introduction: Air enters the tower either through mechanical draft (fan) or natural draft.

Evaporation & heat transfer: A portion of water evaporates, removing latent heat, while the remaining water exchanges sensible heat with air via convection and conduction.

Cold-water collection: Cooled water flows to the basin and is recirculated back to the system.

To achieve efficient cooling, water flows through a closed or semi-closed loop between the cooling tower and the industrial system.

Heat absorption loop: Water absorbs heat from industrial equipment (condensers, heat exchangers).

Pumping system: Circulating pumps deliver hot water to the cooling tower.

Spray system: Nozzles disperse water onto the fill media.

Cold-water return: Cooled water returns to the equipment for reuse.

Two major processes occur:

Mass transfer: Evaporation transfers latent heat as water molecules enter the air.

Heat transfer: Sensible heat is exchanged between water and air through convection and conduction.

Water loss (drift) may also occur, but modern cooling towers use drift eliminators to minimize this.

To ensure stable performance:

Chemical treatment: Prevent scaling, corrosion, and biological fouling.

Water quality monitoring: Regular checks on pH, hardness, microbial levels.

Routine cleaning: Fill, spray nozzles, and basins must be kept clean to maintain efficiency.

Different cooling tower designs affect water circulation efficiency and heat dissipation.

Natural draft towers: Airflow created by chimney effect; ideal for large power plants.

Mechanical draft towers: Fans provide forced or induced airflow.

Counterflow towers: Air enters from the bottom and moves upward against the falling water.

Crossflow towers: Air flows horizontally across falling water; easier to maintain.

|  |  |  |

Fill design: Determines surface area and contact time.

Spray system design: Nozzle type, angle, and flow rate affect water coverage.

Fan control: VFD fans adjust airflow to match cooling demand.

Drift control: Drift eliminators reduce water loss.

As a professional cooling tower manufacturer, Mach Cooling offers significant technical strengths.

Customized design based on heat load and circulation needs

Advanced spray nozzles for uniform water distribution

Stable cooling performance and improved evaporation efficiency

High-performance fill materials (PVC, FRP, aging-resistant plastics)

Lower air resistance and larger surface area

Optimized airflow channels for counterflow or crossflow systems

Recommended chemical treatment solutions

High-efficiency drift eliminators reduce water loss

Improved water quality and extended equipment life

Mach Cooling provides full-system solutions:

Cooling tower + pumps + piping + control systems

Installation guidance, commissioning, and after-sales support

Optimization of water flow, fan speed, and water treatment strategies

To illustrate cooling effectiveness and Mach Cooling’s advantages, consider the following scenario:

Hot water inlet temperature: 45°C

Desired outlet temperature: 32°C

Flow rate: 500 m³/h

Ambient wet-bulb temperature: 25°C

| Item | Standard Cooling Tower | Mach Cooling Optimized System |

|---|---|---|

| Water distribution uniformity | Moderate | Excellent (enhanced nozzle system) |

| Evaporation efficiency | Medium | Higher due to improved fill |

| Cooling capacity | Stable but fluctuates | More stable, accurate temperature control |

| Fan control | Fixed speed | Variable speed (VFD) |

| Drift loss | Higher | Reduced by efficient drift eliminators |

| Water treatment | Basic | Advanced anti-scaling & anti-corrosion |

| Water stability | Fluctuates | More stable, less maintenance |

Illustrate:

Hot water → Circulating pump → Spray system → Fill → Air contact & evaporation → Cold-water basin → Return to equipment

Adjust fan speed based on thermal load

Real-time control via PLC/DCS systems

Ensure uniform water distribution

Use high-efficiency fill with large specific surface area

Monitor pH, hardness, microbial levels

Use effective inhibitors, biocides, and filtration systems

Install efficient drift eliminators

Improve spray patterns and airflow paths

Industrial cooling towers achieve efficient heat dissipation through water circulation + evaporation + heat transfer and play an essential role in industrial thermal management.

The design of the circulation system—including pumps, spray systems, fill, and fan control—directly determines cooling performance, energy efficiency, and system stability.

As a professional manufacturer, Mach Cooling (https://www.machcooling.com/) provides advanced solutions in spray system design, high-efficiency fill, water treatment optimization, and integrated control systems. Their optimized cooling towers deliver improved evaporation efficiency, reduced water loss, and enhanced reliability.

Through proper system design and operational optimization, industrial users can maximize cooling tower performance, reduce operating costs, and enhance long-term stability.