We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-01-09 Origin: Site

Selecting a cooling tower might seem straightforward—just match capacity to your system, right? Not quite. One of the most critical parameters to consider is the approach temperature. Approach temperature determines how close the cooling tower can bring water temperature to the ambient wet bulb temperature. It’s the secret ingredient behind energy efficiency, operational cost, and system lifespan.

Manufacturers like Mach Cooling (https://www.machcooling.com/) design towers that maximize approach performance, ensuring efficient cooling for industrial and commercial applications.

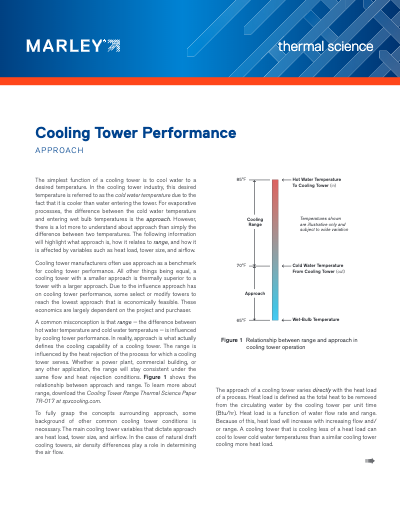

The approach temperature is the difference between the cooling tower’s outlet water temperature and the ambient wet bulb temperature:

[

\text{Approach} = T_\text{outlet} - T_\text{wet bulb}

]

A smaller approach means the tower cools water closer to the wet bulb, indicating higher efficiency.

Wet bulb temperature depends on humidity and ambient conditions. Understanding the difference between approach and wet bulb allows engineers to size towers accurately and predict performance under different weather conditions.

A low approach temperature ensures the system delivers the desired chilled water to downstream equipment. In industrial processes, tight temperature control prevents overheating and protects sensitive machinery.

Optimizing approach temperature reduces the workload on fans and pumps, lowering electricity consumption and operational costs.

Higher ambient wet bulb temperatures naturally increase the outlet water temperature that a tower can achieve, and must be accounted for in design.

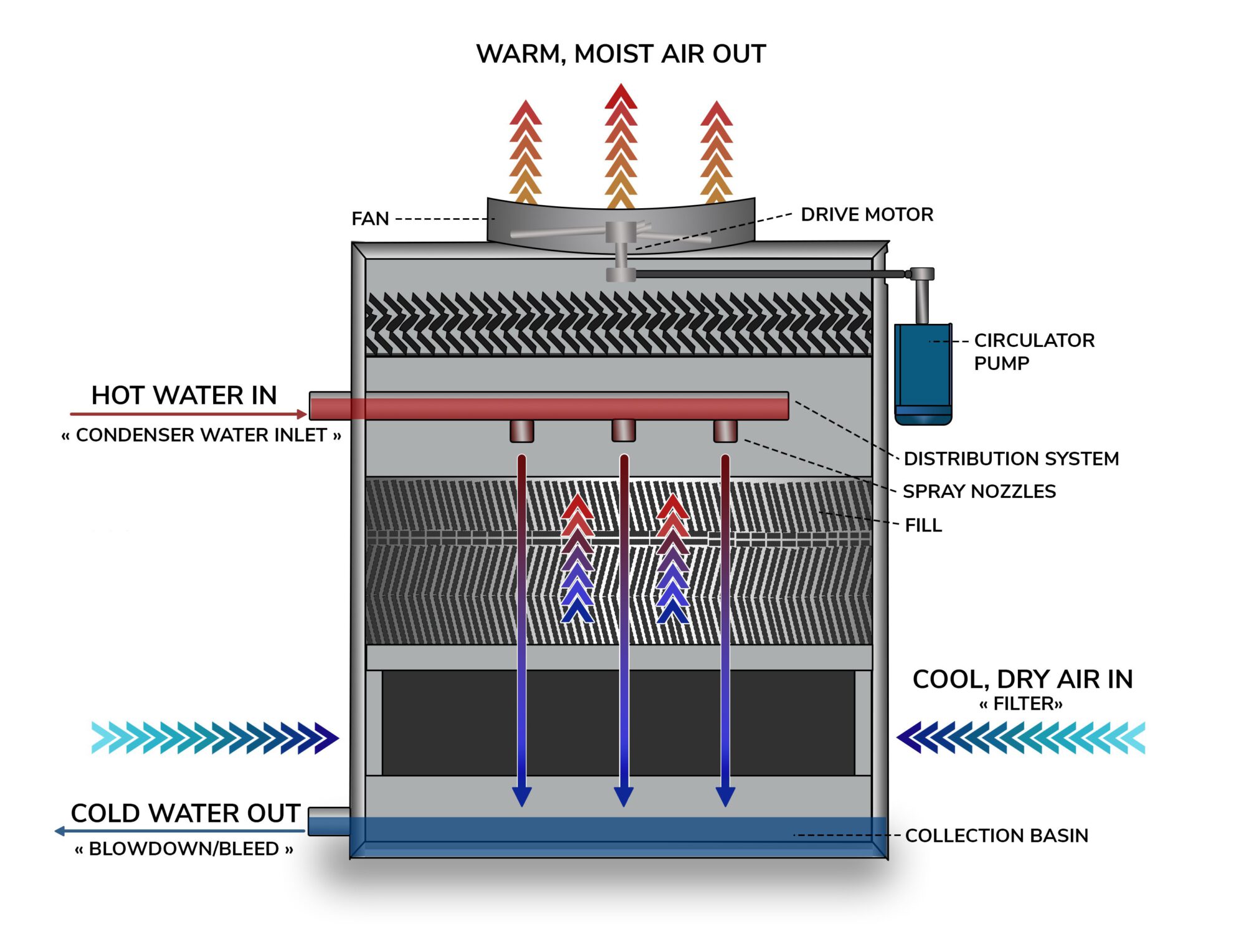

Fill type (splash vs. film), surface area, and tower geometry directly affect heat transfer efficiency and achievable approach.

Water velocity and load fluctuations influence how effectively heat is rejected. Incorrect flow rates can compromise the approach and overall cooling efficiency.

Heavy industries such as power generation or chemical processing require minimal approach temperatures to ensure downstream process efficiency and safety.

In HVAC systems, slightly higher approach temperatures may be acceptable, balancing performance with capital and operational cost.

Traditional open towers can achieve approaches of 5–10°C depending on design, water quality, and environmental conditions.

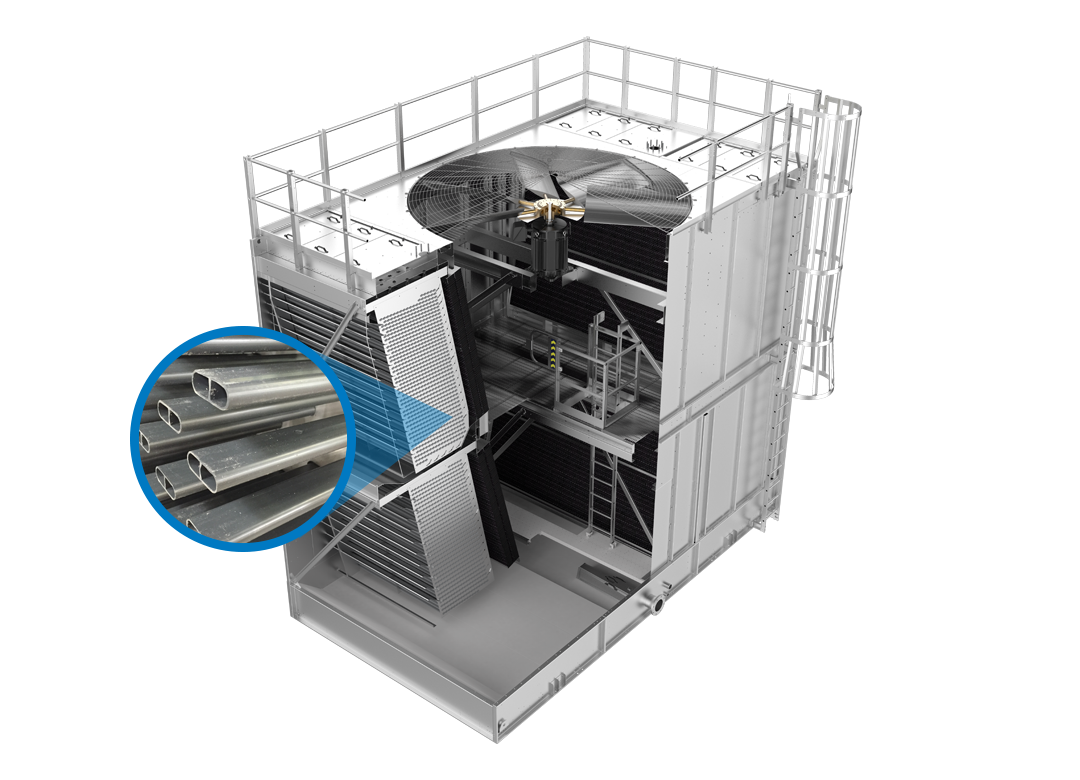

Closed loop towers typically provide lower approach temperatures while protecting process fluid from contamination.

Hybrid systems combine features of open and closed towers, optimizing approach temperature and conserving water.

The design approach temperature is a key factor in determining the heat load the tower can handle. Correct sizing ensures reliable cooling without overloading the system.

Always consult performance curves from manufacturers. Mach Cooling provides detailed approach charts for precise selection and optimal design.

Choosing a tower that meets your required approach reduces unnecessary fan and pump energy consumption, lowering operating costs.

High-efficiency fill materials enhance heat transfer, enabling smaller approaches without increasing tower size.

Deposits, biofilm, and scaling reduce approach efficiency. Periodic maintenance ensures consistent performance.

Modern cooling towers use sensors to monitor water temperature, flow, and ambient conditions to maintain optimal approach continuously.

Oversizing increases capital and energy costs; undersizing compromises cooling. Accurate approach-based sizing strikes the perfect balance.

Wet bulb temperatures fluctuate seasonally. Failing to account for this can lead to underperformance during peak heat periods.

A Southeast Asian factory optimized its tower selection based on approach, reducing outlet temperature by 4°C and saving 12% on energy bills.

A large shopping mall selected a tower with a slightly higher approach temperature, balancing efficiency with lower capital costs while ensuring year-round comfort.

Mach Cooling (https://www.machcooling.com/) focuses on approach optimization through:

Precision coil and fill design

Accurate performance charts and simulations

Custom solutions for industrial and commercial systems

Their engineering ensures towers achieve the desired approach efficiently while conserving energy and water.

Advances in materials, automation, and hybrid designs allow towers to achieve lower approach temperatures without increasing water or energy consumption. Smart cooling towers with real-time monitoring will continue to redefine what’s achievable.

Selecting a cooling tower based on approach temperature is crucial for performance, energy efficiency, and system longevity. Understanding the factors influencing approach, consulting manufacturer data, and maintaining optimal operation ensures your system meets demands reliably.

Partnering with experienced manufacturers like Mach Cooling (https://www.machcooling.com/) transforms approach-based selection into a science, guaranteeing industrial and commercial cooling systems operate at peak efficiency year-round.