We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-12-10 Origin: Site

Choosing the right cooling tower is a critical step for ensuring an efficient, reliable, and long-lasting cooling system — whether for HVAC, industrial processes, or chilled-water applications. A proper selection involves balancing required cooling capacity, water and environmental conditions, future expansion, maintenance needs, and cost. In this article, we’ll walk you through how to select a cooling tower, including open and closed designs, and highlight how a manufacturer like MachCooling (https://www.machcooling.com/) can provide tailored solutions. We’ll also incorporate key terms such as water cooling tower, water cooling tower system, water cooled tower, blowdown water cooling tower, and chilled water cooling tower.

Before you pick a cooling tower, it’s essential to collect baseline data for your application. These parameters will guide you in selecting the right type, size, and configuration. (Mach Cooling)

Determine the heat load your system needs to dissipate — whether it’s from a chiller condenser, industrial equipment, or HVAC load. This is typically expressed in BTU/hr or Tons of Refrigeration (TR).

Establish the water flow rate (e.g., circulating water flow, often in m³/h or GPM). The water cooling tower must handle the volume of water required by your system.

Define the temperature range (delta-T): the difference between inlet (hot) water temperature and desired outlet (cold) water temperature.

These inputs help correctly size the tower so it can meet the thermal load safely and with reliability.

Environmental and installation conditions significantly influence the tower’s performance and suitability. Important factors include:

Ambient air conditions, especially the wet‐bulb temperature (WBT) — since evaporative cooling depends on it. Designers should use the highest expected ambient WBT (worst-case scenario) for sizing.

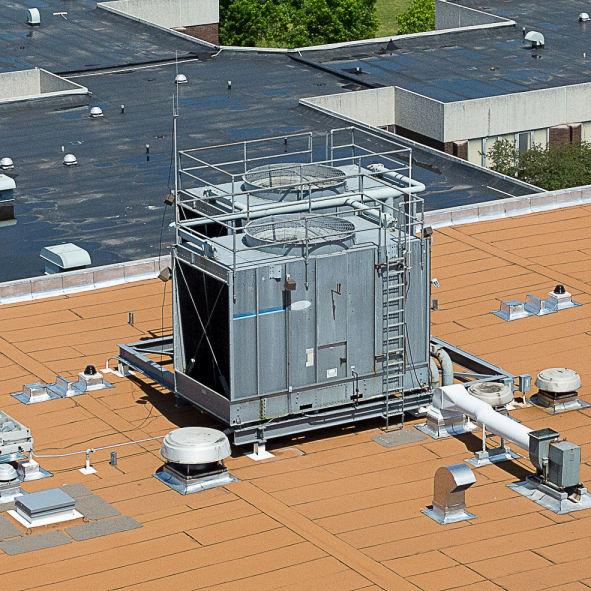

Available space and layout constraints: floor area, height clearance, structural loading (if rooftop), and ventilation must be considered, especially when selecting between “crossflow” vs. “counterflow” designs.

Environmental sensitivities: noise restrictions (in urban or residential zones), proximity to buildings, airflow obstructions, or exposure to dust or corrosive atmospheres. (Mach Cooling)

The quality of circulating water affects both performance and maintenance needs. Key aspects to evaluate:

Water hardness, dissolved salts (e.g., chlorides), suspended solids, pH, and overall chemical composition. High hardness or corrosive water may demand more robust materials or water treatment. (Mach Cooling)

The need for water treatment, filtration, or softening depending on water quality and cycles of concentration. Poor water quality can lead to scaling, fouling, corrosion — degrading cooling efficiency and shortening tower lifespan.

If water quality or maintenance resources are limited, a closed-circuit (closed-loop) water cooled tower may be more appropriate to avoid direct exposure of process water to environmental contaminants. (Mach Cooling)

Selecting the type of tower is just as important as sizing. Here are the common categories and how to choose between them.

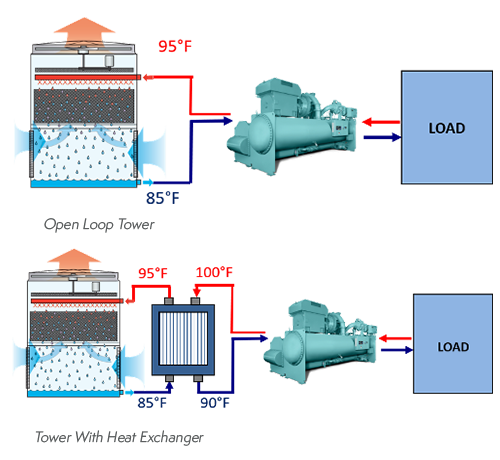

Definition: These towers expose circulating water directly to air; heat is removed via evaporation. Commonly used for HVAC, general industrial cooling, and condenser water loops.

Advantages: Lower initial cost; simpler structure; easier maintenance; common and widely supported.

Limitations: Water is exposed to the environment — meaning water quality challenges (scale, fouling, biological growth) can reduce efficiency and increase maintenance needs; may need regular blowdown, treatment, filtration.

Use open towers when water quality is manageable (or treated), and maintenance and blowdown are acceptable — e.g., typical condenser water systems or general process cooling.

These towers isolate process fluid (e.g., chilled water, sensitive process water) from the external “cooling water,” preventing cross-contamination. A coil or heat exchanger circulates the process fluid, while cooling water circulates in the tower for evaporation. (Mach Cooling)

Advantages: Cleaner, safer for sensitive processes (food, pharmaceuticals, data centers, chillers, etc.); reduced water treatment needs; enhanced water quality stability; less frequent maintenance. (Mach Cooling)

Trade-offs: Higher initial cost (often 40–60% more expensive than comparable open towers) (Mach Cooling)

Closed-circuit towers are often ideal for a chilled water cooling tower or where blowdown water cooling tower is undesirable due to water waste, environmental regulations, or water scarcity.

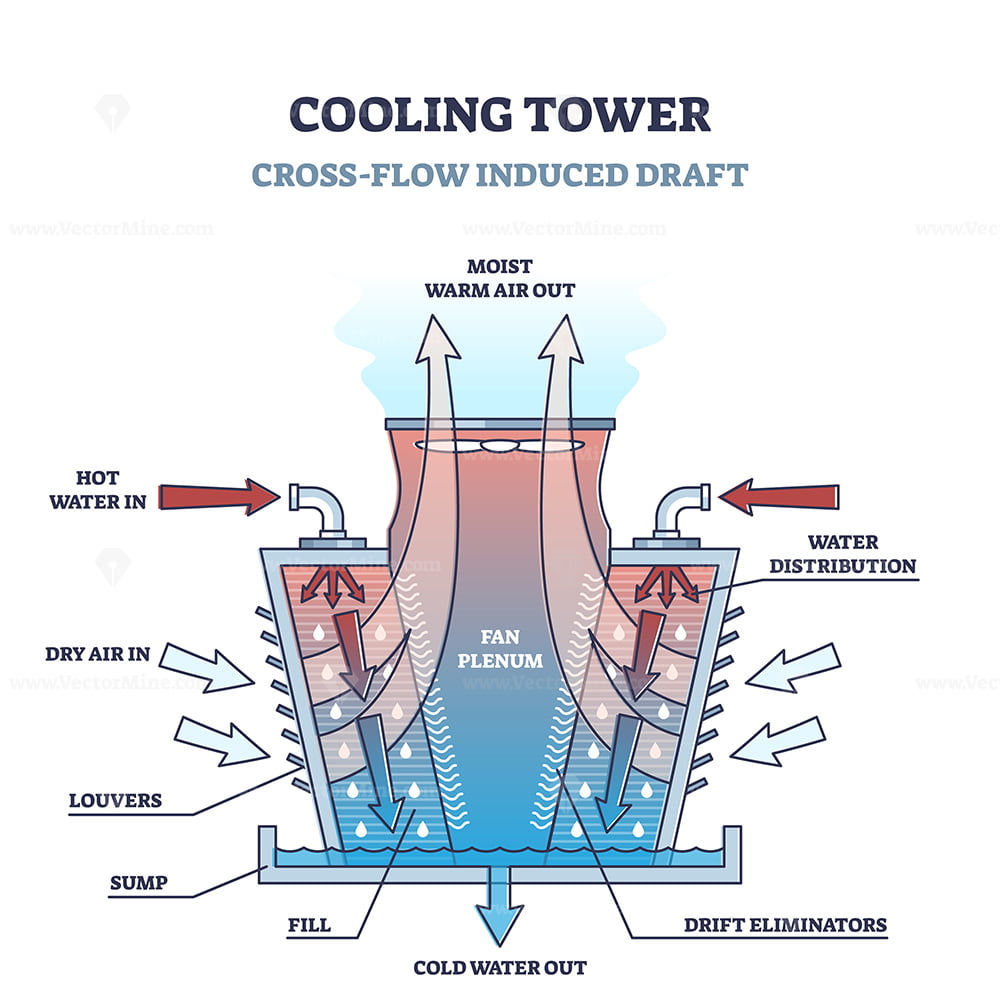

When selecting an open or closed tower, you’ll also need to pick air-water flow configuration.

| Flow Type | Advantages / Use Cases |

|---|---|

| Crossflow | Easier maintenance and inspection; better for variable loads (good “turndown” ability — i.e., perform well under partial load). |

| Counterflow | Higher heat exchange efficiency; more compact footprint (less floor space) — good when site footprint is limited. (Mach Cooling) |

Your site constraints (space, maintenance access, load variability) will influence this choice.

Here are common application scenarios and how they map to tower types and specifications.

Typical load: condenser water for chillers, or building air-con systems.

Recommended: Open “water cooling tower” or “water cooled tower,” crossflow or counterflow depending on space and maintenance access; ensure water treatment and blowdown plan.

If water quality is poor, or maintenance difficult, consider closed-circuit variants.

For general industrial processes (not sensitive fluids): open towers are often preferred due to cost-effectiveness.

For processes sensitive to contamination, or requiring very stable water quality — use closed-circuit cooling towers.

Chillers, data centers, pharmaceutical, food processing: closed-circuit or hybrid towers are often the best choice (i.e., a “chilled water cooling tower” or “water cooling tower system” designed for sensitive water loop).

Ensures minimal risk of contamination, provides stable outlet water, and lower long-term maintenance.

Here is a practical checklist you can use when selecting a cooling tower — followed by a sample spec-comparison table to help decide between options.

Define cooling load (BTU/hr or TR) and water flow rate.

Determine design inlet (hot) water temperature and required outlet (cold) water temperature.

Check local ambient design wet-bulb temperature (WBT) (use worst-case).

Confirm site constraints: footprint, height, load-bearing capacity, noise, ventilation, nearby obstacles.

Evaluate water quality: hardness, salts, suspended solids, pH, contaminants.

Decide tower type: open vs closed; crossflow vs counterflow; material and packing type (consider water quality and temperature).

Review water treatment & blowdown plan, including filtration, water softening, chemical dosing, blowdown control, cycles of concentration.

Consider future needs: expansion margin, maintenance access, life-cycle costs, energy efficiency (fan motors, pump efficiency), noise, drift control, environmental compliance.

Request detailed manufacturer data (performance curves, capacity correction factors, materials, expected maintenance intervals).

If possible, select towers from experienced manufacturers (like MachCooling) who can tailor systems to your needs.

| Parameter / Requirement | Option A: Open Crossflow Tower | Option B: Closed-Circuit Cooling Tower |

|---|---|---|

| Application | HVAC condenser water, general industrial cooling | Chilled water loop, sensitive process water |

| Water Quality Sensitivity | Medium — requires good water treatment & filtration | Low — fluid is isolated, minimal contamination risk |

| Footprint / Space | Larger (needs more floor area) | Smaller footprint, more compact |

| Initial Cost | Lower | Higher (≈ 40–60% more) (Mach Cooling) |

| Maintenance Frequency | Higher (scaling, blowdown, filtration, water treatment) | Lower (less contamination, simpler water loop) |

| Water Treatment Complexity | High — must manage water chemistry, blowdown cycles | Lower — closed loop reduces evaporation losses and contamination |

| Typical Use Cases | Air conditioning, general industrial cooling | Chillers, data centers, pharmaceutical/food industries, sensitive equipment |

Using a reputable supplier like MachCooling improves chances of getting a cooling tower tailored to your needs. Here’s how:

MachCooling offers a full catalogue of cooling towers: open-circuit water cooling towers, closed-circuit (evaporative condenser) towers, and hybrid solutions — enabling you to choose the best fit. (Mach Cooling)

They provide detailed performance curves and selection guides: based on your input (flow rate, temperature range, wet-bulb, application), MachCooling can calculate the proper tower capacity and configuration — avoiding over- or under-sizing. (Mach Cooling)

They accommodate various water qualities: offering different materials (FRP, stainless steel, different packing media) so that your “water cooled tower” or “chilled water cooling tower” remains durable even under challenging water conditions. (Mach Cooling)

MachCooling can support accessory and system-level needs: water treatment guidance, blowdown water cooling tower designs, and support for long-term maintenance and lifecycle optimization.

By partnering with a manufacturer like MachCooling, you benefit from integrated design, compliance with industrial standards, and support for long-term efficiency and reliability.

Selecting the right cooling tower is more than just picking a size. It’s about understanding your system’s thermal demands, water quality, site constraints, and long-term maintenance needs.

Key takeaways:

Always begin with accurate data: cooling load, flow rate, inlet/outlet temperature, ambient WBT, water quality.

Choose the tower type (open vs closed), flow configuration (crossflow vs counterflow), and materials intelligently — based on application, water quality, and space.

For sensitive applications or poor water quality, closed-circuit or hybrid towers can offer long-term savings and stability.

Always incorporate water treatment / filtration / blowdown planning. Water quality affects both efficiency and lifespan significantly.

Work with a reliable manufacturer (e.g., MachCooling), request performance curves and detailed specs, and plan for maintenance, future expansion, and water treatment.