We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-12-10 Origin: Site

In modern industrial and HVAC systems, a well-designed and maintained water cooling tower plays a vital role in controlling process water temperatures. Whether it is a “water cooling tower,” “water cooling tower system,” or a “chilled water cooling tower,” optimizing performance often means reducing the temperature of the water leaving the tower. Lowering the “cooling tower inlet and outlet water temperature” not only improves energy efficiency but also enhances the lifetime and reliability of the entire system. In this article, we examine methods and best practices — including filtration, treatment, system configuration, and maintenance — highlighting how a manufacturer like MachCooling (https://www.machcooling.com/) can help you implement an efficient, high-performance cooling tower system.

A cooling tower functions by removing heat from warm water (e.g. from a chiller condenser or industrial process) and rejecting that heat to the ambient air via evaporative cooling. Water is distributed over “fill media” and air flows through (or across) that media: as part of the water evaporates, the remaining water cools down and returns to the system.

According to standard reference data, a properly designed cooling tower can cool water to within about 4–5 °F (≈2–3 °C) of the ambient wet-bulb temperature — often 30–35 °F (≈17–19 °C) cooler than comparable air-cooled systems of similar size.

However, in practice achieving and maintaining low outlet temperatures depends heavily on system design, water quality, maintenance, and control strategies.

Key terms to know:

Cooling tower inlet water temperature: the temperature of water entering the tower (from chiller/condenser or process).

Cooling tower outlet water temperature (or return / cold-water temperature): the temperature of water leaving the tower after cooling.

Approach temperature: the difference between outlet water temperature and ambient wet-bulb temperature — a smaller approach means more efficient cooling.

Here are some of the most effective strategies to lower cooling tower outlet water temperature — many of which can be implemented (or optimized) by a professional supplier like MachCooling.

Ensure the fill media is clean, in good condition, and appropriately selected (e.g. film-fill or splash-fill depending on application). This maximizes surface area for water-air interaction.

Guarantee even and balanced water distribution across the fill media — avoid uneven flow, which can reduce efficiency and lead to warmer outlet water.

Operate all towers (or all cells) simultaneously — rather than staging one at a time — especially if variable-speed fans (VSD) are available. This generally yields better cooling and more efficient energy use.

Use a “condenser water reset strategy”: adjust the outlet temperature set-point relative to ambient wet-bulb temperature (e.g. set outlet water at ~5 °F above wet-bulb, or lower if system allows).

These operational optimizations make sure the tower works at its design potential, maximizing evaporative cooling and minimizing “approach temperature.”

Sometimes, an open-loop cooling tower alone cannot achieve the low water temperatures needed for sensitive processes or chiller systems. In those cases:

Use a separate heat exchanger (plate or shell-and-tube) between the cooling tower and process/chiller loop. This can improve the “approach” by 2–3 °F (1–2 °C).

Use a packaged “fluid cooler” or closed-loop cooling tower — a pre-assembled unit — if space and budget allow. Though fluid coolers may result in slightly higher water temperatures than ideal open towers, they offer better control and often lower maintenance complexity.

These options are particularly valuable for “chilled water cooling tower” applications or where the “condenser water system” demands tight temperature control for optimal performance.

Water quality is a critical — and often underestimated — factor in cooling tower performance. Poor water quality can lead to scaling, fouling, biofilm formation, sediment deposition: all of which degrade heat transfer efficiency and raise outlet temperatures.

Key practices:

Install a filtration system (side-stream or full-stream): Side-stream filtration (filtering ~5–15% of circulation flow) removes suspended particles and prevents build-up that reduces efficiency.

Use proper chemical treatment: Scale inhibitors, corrosion inhibitors, biocides, and dispersants help prevent mineral scaling, biological growth, and corrosion — all of which impair heat transfer.

Softening or pre-treatment of make-up water when hardness is high: Pre-treating make-up water via softening or reverse osmosis reduces the concentration of calcium and magnesium ions, reducing scale formation and allowing the system to maintain high “cycles of concentration.”

Blowdown management & cycles of concentration monitoring: Properly controlling blowdown (bleed-off) and tracking conductivity helps manage dissolved solids — too high solids degrade tower performance.

A well-maintained water cooling tower system with filtration and treatment is more likely to achieve lower outlet water temperatures and sustain them over time.

Even the best-designed tower will perform poorly without proper maintenance. Key maintenance tasks include:

Periodic cleaning of fill media, drift eliminators, basins, distribution decks and nozzles — to prevent fouling, deposit build-up, or blockages.

Routine checks and calibration of blowdown, make-up water flow, conductivity, and concentration cycles to ensure water chemistry remains within the target range.

Monitoring and maintaining fan performance, correct airflow, water distribution balance, and other mechanical components, because airflow and water flow are fundamental to evaporative cooling efficiency.

Consistent maintenance and proper water/water-treatment regime often yield improved cooling without large capital investment.

| Strategy / Measure | Purpose / Effect | Impact on Water Temperature / System Efficiency |

|---|---|---|

| Proper fill media & balanced water distribution | Maximize water–air contact area, even flow across tower | Lower outlet water temperature; improved evaporative cooling efficiency |

| Operating all towers/cells + fan staging | Maintain stable, uniform cooling load distribution | Consistent outlet temperature; avoid hot spots |

| Use of closed-loop or fluid cooler with heat exchanger | Isolate process water from open-loop; tighter temperature control | Achieve closer approach temperatures; stable chilled water temps |

| Side-stream filtration / full-stream filtration | Remove suspended solids, prevent fouling & scaling | Maintain efficient heat-transfer surfaces; stable cold-water output |

| Water softening / pre-treatment | Reduce mineral hardness & scale formation | Lower scaling risk; sustain efficient heat transfer over long run |

| Chemical treatment (scale, corrosion, biocide) + blowdown control | Prevent scale, biological growth, corrosion | Maintain system health and steady cooling capacity |

| Regular cleaning and mechanical maintenance | Ensure fans, nozzles, fill, distribution system function optimally | Avoid degradation of cooling efficiency; keep outlet water temperature low |

As a cooling tower manufacturer and solutions provider, MachCooling (https://www.machcooling.com/) can help clients implement the above strategies via:

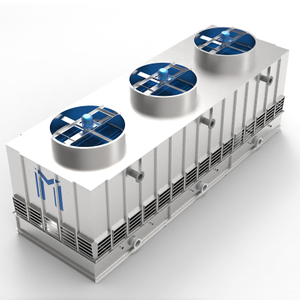

Supplying high-quality water cooling tower systems (open-loop, closed-circuit, or hybrid) tailored to client’s process or HVAC demands (tons cooling, flow rates, tower sizing).

Providing options for chilled water cooling tower configurations or towers designed for condenser water loops, ensuring design is optimized for your inlet/outlet water temperature requirements.

Offering compatible water filtration systems (side-stream filters, multimedia filters, basin-sweepers) integrated into the cooling tower or as an add-on, to control suspended solids and maintain long-term efficiency.

Advising on water treatment solutions (softening, chemical dosing, blowdown control) — reducing scaling, corrosion, and biofouling risks.

Supplying maintenance and operation guides or services to ensure water distribution, fan operation, and water chemistry remain within optimal specs over time.

By working with a specialist manufacturer, you gain access to end-to-end solutions — not just the tower shell, but the entire “water cooling tower system,” tailored to your project’s thermal loads, water quality, and efficiency goals.

Reducing cooling tower water temperature — and keeping it stable — is a multi-faceted task. It requires a combination of good design, proper water treatment and filtration, smart operation and control, and regular maintenance.

Key takeaways:

Focus not only on the tower hardware but also on water quality, filtration, and treatment. Neglecting them undermines cooling performance, no matter how good the tower is.

Optimize air-water contact by balancing flow and using appropriate fill media, ensuring water is evenly distributed and air flows properly.

Consider closed-loop or heat-exchanger solutions when very low chilled or condenser water temperatures are required.

Partner with a professional provider — such as MachCooling — who understands integrated cooling tower systems, water treatment, and long-term maintenance.

With the right approach, many water cooling tower systems can consistently deliver effective cooling, lower outlet temperatures, improved energy efficiency, and long service life — delivering real value to industrial, commercial, or HVAC applications.