We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-12-20 Origin: Site

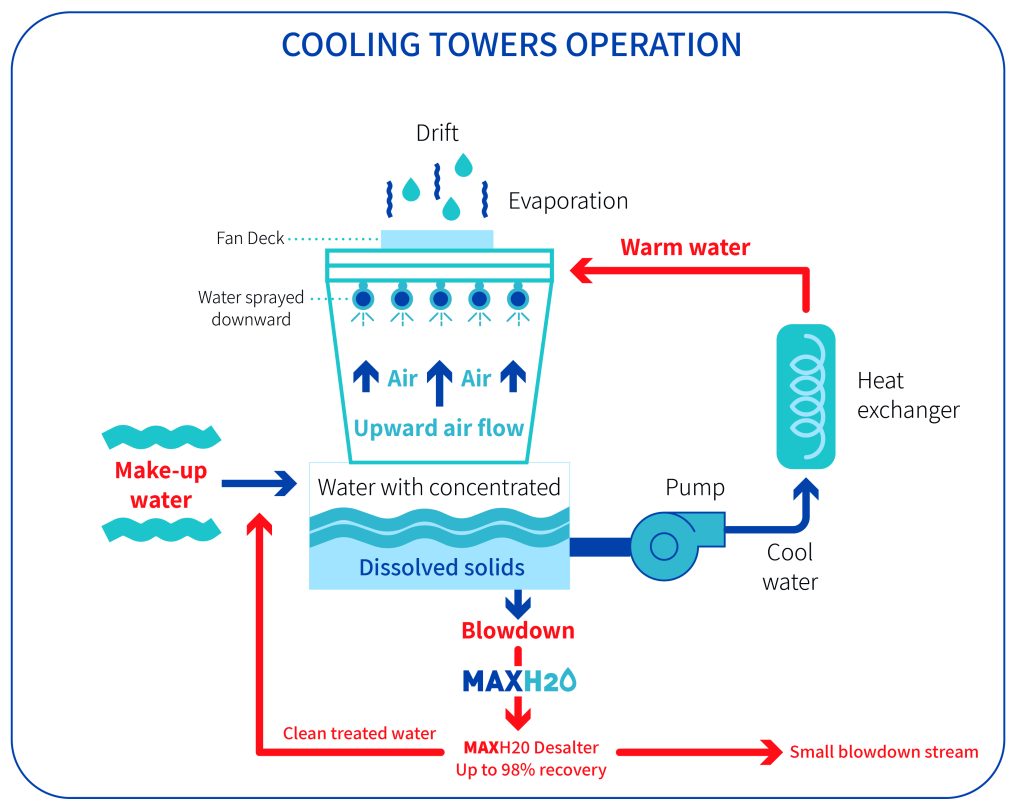

Efficient water management is a critical aspect of cooling tower operation — especially for water cooled tower, blowdown water cooling tower, cold water basin cooling tower, and systems connected to a cooling tower chilled water system. Blowdown is the portion of water intentionally discharged from a cooling tower to control the concentration of dissolved solids and prevent scaling, corrosion, or biological growth in the circulating water loop. However, excessive cooling tower blowdown water increases costs, consumes resources, and can present environmental challenges.

In this article, we explain why blowdown happens, how to reduce it, and best practices you can implement — all while highlighting how Mach Cooling (https://www.machcooling.com/), a trusted cooling tower manufacturer, can support your optimized system design.

Blowdown — sometimes called bleed-off — is water discharged from a cooling tower to control the level of dissolved minerals. When water evaporates (the primary cooling mechanism), the minerals remain and increase in concentration. Without blowdown, dissolved solids can reach damaging levels, leading to scale formation, corrosion, and system inefficiencies.

Cooling towers lose water in four main ways:

| Loss Type | Description |

|---|---|

| Evaporation | Water evaporated to remove heat |

| Drift | Water carried out as tiny droplets |

| Blowdown | Water discharged to control dissolved solids |

| Leaks/Overflows | Unintended water loss |

Strong water management helps reduce unnecessary blowdown while keeping the system healthy.

Reducing blowdown involves maintaining water quality so that the system can safely operate at higher concentrations of dissolved solids before needing to discharge water.

Cycles of concentration (COC) measures how many times water circulates before being discharged relative to makeup water. Higher COC means lower blowdown volume.

How to increase COC:

Improve water treatment to control scaling and corrosion

Use softening or pretreatment systems for makeup water

Monitor conductivity and solids levels continuously

Example Target COC Table

| System Type | Typical COC | Impact on Blowdown |

|---|---|---|

| Poor water quality | 2–3 | High blowdown |

| Well-treated system | 5–7 | 20–40% less blowdown |

| Advanced treatment | 7+ | Significant water savings |

By increasing cycles of concentration, water can be retained longer in the system, reducing cooling tower blowdown water discharged.

A balanced chemical program protects surfaces and keeps dissolved solids under control. Excessive or insufficient chemicals can cause early blowdown due to scaling or corrosion concerns.

Treatment tips:

Use corrosion and scale inhibitors

Maintain biological control to prevent algae and slime buildup

Apply automated chemical feed systems to respond to real-time conditions

Proper treatment ensures your cold water basin cooling tower water remains in good condition at higher COC.

Installing sensors and automatic control valves that base blowdown on conductivity or total dissolved solids (TDS) prevents unnecessary water discharge.

Benefit:

Instead of time-based blowdown, water is only discharged when needed to maintain your desired COC threshold — reducing wasted cooling tower blowdown water.

Filtering water removes suspended solids and reduces the rate at which dissolved solids accumulate, allowing longer intervals between blowdowns.

Common filtration methods:

Side-stream filters

Ultrafiltration

Reverse osmosis (RO) pretreatment

Pretreated makeup water — especially via RO — has lower dissolved solids and increases system efficiency, meaning blowdown water cooling tower rates are significantly lowered.

Instead of discharging blowdown directly to sewer systems:

Reuse options include:

Irrigation and landscaping

Dust control or cleaning water

Makeup water after proper treatment

Treat and reuse blowdown to conserve water and lower operational costs.

Improving airflow, heat transfer, and general operation of your water cooled tower reduces the amount of makeup water needed in the first place. Efficient systems produce less blowdown by minimizing unnecessary evaporation and heat load.

The right technologies can help your cooling tower chilled water system manage water more intelligently.

Modern automation systems monitor:

Conductivity

Temperature

Water level

…and automatically adjust blowdown rates to the minimal needed levels.

Tools such as:

Reverse Osmosis systems

Side-stream filtration

Ion exchange softeners

improve makeup water quality and reduce total dissolved solids, enhancing overall efficiency.

Managing blowdown sustainably requires attention to both operational practices and environmental considerations.

Define acceptable levels for dissolved solids, cycles of concentration, and blowdown frequency. Regular logging of these metrics helps you see trends and make adjustments before issues escalate.

Routine inspection and maintenance help catch issues — such as failed float valves or sensor drift — that can cause unnecessary blowdown.

Using alternative water sources for makeup reduces fresh water demand and total blowdown volume. This includes:

Rainwater harvesting

Greywater reuse

Air handler condensate capture

Mach Cooling (https://www.machcooling.com/) is a premier cooling tower manufacturer offering tailored solutions for water management in HVAC and industrial systems. Their expertise includes:

Custom design of blowdown water cooling towers

Integration with water treatment systems

**Support for water cooled tower, cold water basin cooling tower, and cooling tower chilled water system applications

Working with experienced experts ensures that your system is optimized from design through operation — maximizing efficiency while minimizing water loss.

Maximize cycles of concentration to reduce blowdown water volumes.

Use smart blowdown control systems and sensors to discharge water only when needed.

Improve water quality and filtration to lower solids buildup.

Treat and reuse blowdown where feasible for sustainability.

Partner with manufacturers like Mach Cooling for customized, efficient designs.

Reducing cooling tower blowdown not only conserves water but also cuts costs, improves equipment life, and supports sustainability goals.