We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-01-10 Origin: Site

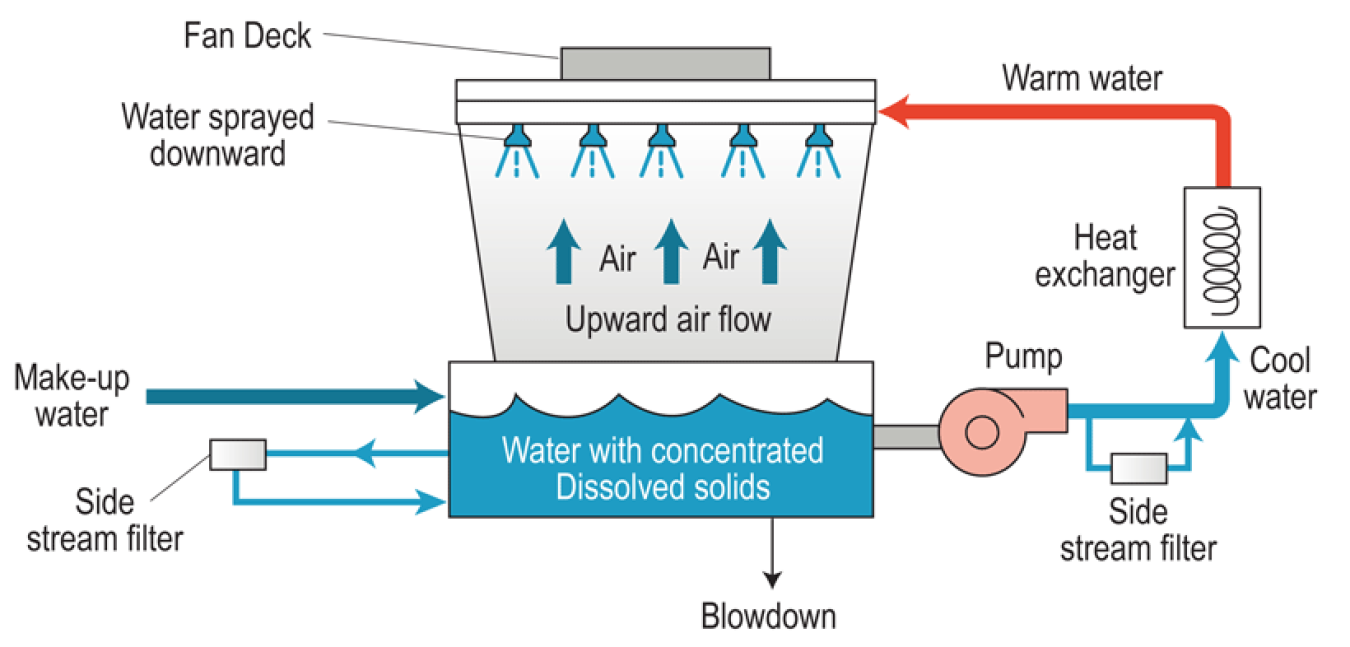

Cooling towers are the unsung heroes of industrial systems, quietly rejecting heat to keep processes running smoothly. Yet, even the most advanced cooling tower can struggle if the filter isn’t properly maintained. Filters remove debris, prevent fouling, and protect critical components. Neglecting them is like trying to drive a car with a clogged air filter—you might move, but at higher cost and risk of breakdown.

Maintaining cooling tower filters is essential for long-term performance, energy efficiency, and system reliability. In this guide, we’ll cover everything you need to know about cooling tower filter maintenance.

A cooling tower filter captures particulate matter, sediment, and biological debris from circulating water. Its main goal is to protect the system, reduce fouling, and maintain clean heat transfer surfaces. Without an effective filter, debris can settle on fill media, block nozzles, and even damage pumps and fans.

Side Stream Filters: Continuously treat a portion of water, gradually reducing suspended solids.

Full Flow Filters: Filter all water passing through the tower for maximum protection.

Automatic Backwash Filters: Clean themselves automatically, reducing manual labor and downtime.

Manual Screens or Mesh Filters: Simple and cost-effective but require frequent manual cleaning.

Filters are the first line of defense against dirt, rust, and other particulates. Clean water ensures stable heat transfer and prevents scale formation.

Pumps, valves, and fill media are vulnerable to sediment and debris. A well-maintained filter prevents costly mechanical failures.

Debris and fouling reduce airflow and water contact efficiency. Filters help maintain optimal heat transfer, keeping energy consumption low.

If water isn’t circulating at the designed rate, a clogged filter may be the cause.

Significant increases in differential pressure across the filter indicate sediment buildup.

Physical inspection may reveal leaves, algae, or other particulate matter that restrict water flow.

Regularly inspect filters for wear, sediment, or damage. Check the housing, screens, and seals.

Manual Cleaning: Remove debris and rinse with high-pressure water.

Chemical Cleaning: Use mild descaling agents if necessary.

Automated Backwash: For automatic filters, ensure timers and cycles are functioning correctly.

Over time, filter media wears out. Replace it according to the manufacturer’s recommendations to ensure continuous performance.

Leaky gaskets reduce filtration efficiency and may allow debris bypass. Inspect and replace damaged seals promptly.

Even a clean filter can’t prevent scale buildup. Combine proper filtration with water treatment chemicals to inhibit scaling.

Algae and bacteria thrive in warm, nutrient-rich water. Filters remove large particulates, but chemical biocides and routine cleaning are essential to control microbial growth.

A coarse pre-filter upstream can extend the life of the main filter and reduce maintenance frequency.

Automated backwash systems save labor, maintain consistent efficiency, and prevent unexpected blockages.

Track differential pressure, flow rate, and water quality to detect issues before they impact performance.

Ignoring regular inspections

Using improper cleaning agents

Delaying filter media replacement

Neglecting gaskets and seals

Failing to integrate with water treatment programs

Avoiding these mistakes ensures your system operates efficiently and reliably.

Reduced energy consumption

Longer equipment lifespan

Lower water treatment costs

Enhanced heat transfer efficiency

Fewer unplanned shutdowns

At Mach Cooling (https://www.machcooling.com/), filters are designed for durability, high efficiency, and easy maintenance. Their solutions:

Are custom-engineered for industrial applications

Include advanced filtration technologies

Integrate seamlessly with water treatment systems

Provide long-term support and technical guidance

Partnering with a professional manufacturer ensures your cooling tower performs at peak efficiency for years.

Maintaining a cooling tower filter is critical for long-term performance. From routine inspections to integrating with water treatment, every step contributes to energy savings, equipment longevity, and operational reliability.

With proper maintenance and the right partner like Mach Cooling, your industrial system can enjoy continuous, efficient, and trouble-free operation. Remember, a clean filter isn’t just a small part—it’s the key to keeping your entire cooling system running smoothly.