We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-12-22 Origin: Site

Cooling towers are essential for rejecting heat in industrial processes and HVAC systems — from water cooled tower systems to chilled water cooling towers. Improving cooling tower efficiency not only lowers operating costs but also extends equipment lifespan and reduces water consumption.

This article explains how to increase cooling tower efficiency, covering design choices, maintenance practices, and performance optimization strategies. We reference solutions provided by Mach Cooling Tower (https://www.machcooling.com/), including closed type cooling towers, dry type cooling towers, closed circuit cooling towers, round cooling towers, square cooling towers, and FRP cooling towers.

An efficient cooling tower delivers:

Lower cooling water temperature

Reduced energy consumption

Less water waste

Improved system reliability

Key influencing factors include airflow distribution, water distribution, environmental conditions, and system maintenance.

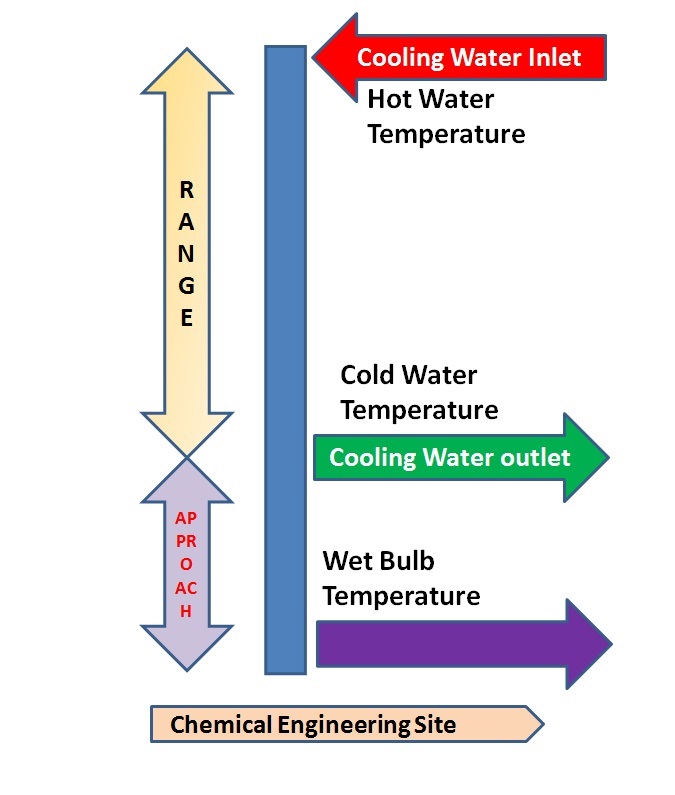

Cooling tower efficiency is typically defined as:

[

\text{Efficiency} = \frac{\text{Actual Cooling}}{\text{Ideal Cooling}} × 100%

]

Where “ideal cooling” assumes the lowest possible temperature (approach) given the current wet-bulb temperature.

| Metric | Description |

|---|---|

| Approach | Difference between cooled water and wet-bulb temp |

| Range | Difference between inlet and outlet water temp |

| Cycles of concentration | Ratio of dissolved solids in circulating water |

Selecting the appropriate system lays the foundation for efficiency.

Closed circuit cooling towers use coils that prevent contamination of the process fluid, improving heat transfer and operational reliability.

Easy water quality management

Lower fouling risk

Ideal for chilled water cooling towers

Mach Cooling Tower provides advanced closed circuit systems tailored for various industrial applications.

Closed type cooling towers are similar to closed circuit but often incorporate enhanced coil and spray distribution designs for improved performance.

A dry type cooling tower uses only air for heat rejection, eliminating evaporation losses. While efficiency is influenced by ambient air conditions, proper design can yield high performance without water consumption.

Round cooling towers enhance airflow uniformity, providing efficient heat rejection with a compact footprint.

Square cooling towers offer modular expandability and can achieve high water distribution efficiency when properly engineered.

FRP cooling towers combine structural strength with corrosion resistance, leading to longevity and stable performance under harsh environments.

Adequate airflow prevents hot air recirculation. Strategies include:

Maintaining fan blades

Ensuring clear inlet and outlet paths

Using variable speed drives (VFDs)

Blocked or restricted airflow significantly reduces efficiency.

Uniform water distribution ensures every fill media area participates in cooling. Uneven distribution leads to hot spots and reduced performance.

Good practices:

Clean spray nozzles regularly

Replace worn distribution systems

Monitor distribution patterns visually

Water quality affects heat transfer.

Control scaling (via chemical treatment)

Minimize biological growth

Monitor pH and dissolved solids

Clean water helps maintain efficiency and reduces fouling on fill and coils.

| Indicator | Target |

|---|---|

| Approach | Lower is better |

| Range | Higher is better |

| Water loss | Minimal at optimal efficiency |

| Power use | Reduced when efficient |

Use sensors to track:

Inlet/outlet water temperatures

Wet-bulb temperature

Water flow rate

Fan motor energy consumption

Fill media increasess heat transfer surface. Fouled or blocked fill reduces cooling capacity.

Maintenance tasks:

Periodic chemical cleaning

Remove sediment and scale

Replace damaged fill sections

Fan inefficiency reduces airflow. Check and balance blade alignment, belts, and motor operation.

Ensure drift eliminators function correctly to reduce drift loss and conserve water.

Cooling tower efficiency should be linked with sustainability:

Cool water tower water management reduces consumption

Optimized cycles of concentration decrease blowdown

Efficient makeup water control minimizes water withdrawal

Combining operational improvements with good design enhances both performance and environmental outcomes.

| Area | Action | Expected Benefit |

|---|---|---|

| Water distribution | Clean and adjust spray nozzles | Uniform cooling, higher heat transfer |

| Airflow | Remove obstructions, adjust fans | Reduced recirculation, better cooling |

| Water quality | Chemical control program | Minimized scaling, longer fill life |

| Monitoring | Install sensors | Early alerts, performance trend tracking |

Mach Cooling Tower (https://www.machcooling.com/) provides engineered cooling systems that include:

Closed circuit cooling towers for clean, efficient operation

Closed type cooling tower designs for industrial systems

Dry type cooling towers for zero water usage applications

Round cooling towers and square cooling towers to fit any spatial constraint

FRP cooling tower options for corrosion resistance

Water cooled tower and chilled water cooling tower solutions for HVAC and process cooling

Their experienced engineering team ensures each system is sized and configured for maximum efficiency.

Increasing cooling tower efficiency is achievable through:

Smart design choices (tower types and structure)

Proper operational practices (airflow and water distribution)

Rigorous maintenance

Real-time performance monitoring

Effective water quality management

Whether you need a water cooled tower for industrial cooling or a chilled water cooling tower for HVAC systems, working with professional manufacturers like Mach Cooling Tower guarantees reliable, efficient solutions that reduce cost and conserve water.