We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-12-22 Origin: Site

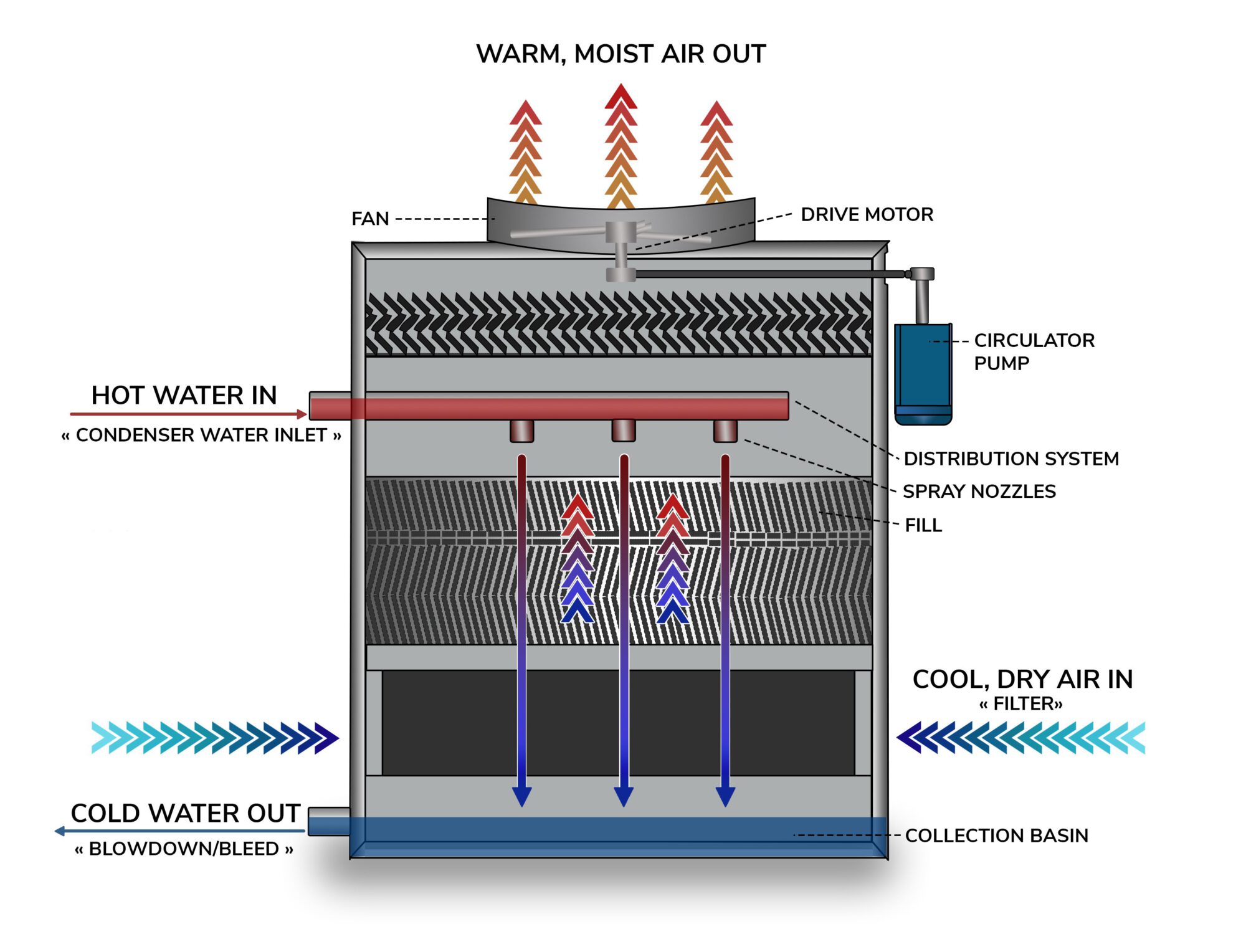

In any water cooling tower system, understanding and accurately calculating cooling tower makeup water is essential for efficient operation, cost control, and sustainable water use. Makeup water replaces the water lost through evaporation, blowdown, drift, and leakage during normal cooling tower operation.

This article explains how to calculate makeup water for a cooling tower, covering formulas, rule-of-thumb methods, and practical considerations such as cooling tower condenser water loops, water loss calculation, and water management. Examples are aligned with engineering practices used by Mach Cooling Tower (https://www.machcooling.com/), a professional manufacturer of industrial cooling solutions.

Cooling tower makeup water (also written as cooling tower make up water) is the fresh water supplied to a cooling tower to maintain the required cooling tower water level and stable system operation.

Makeup water compensates for:

Evaporation loss

Blowdown (bleed-off)

Drift loss

Minor leaks and overflow

Without proper makeup water control, the cooling tower condenser water system cannot maintain stable temperature or flow.

Accurate cooling tower makeup water calculation helps:

Control cooling tower water consumption

Improve cooling tower water efficiency

Reduce operating cost

Support cooling tower water conservation

Protect equipment and water quality

Mach Cooling Tower designs cooling systems with optimized makeup water balance to support long-term reliability.

The basic water balance for a cooling tower is:

Makeup Water=Evaporation+Blowdown+Drift+Leakage

This formula is the foundation of all cooling tower water losses calculation methods.

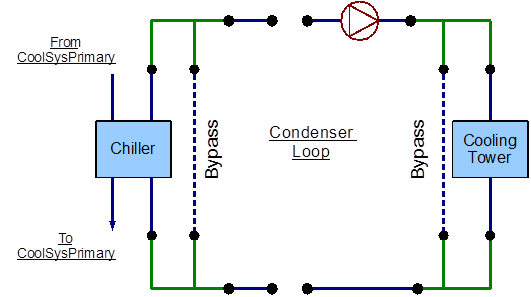

In a cooling tower condenser water loop, warm water exits the condenser, enters the cooling tower, and returns cooled.

Key operating parameters include:

Cooling tower inlet and outlet water temperature

Cooling tower water flow rate

Cooling tower water level and level control

Evaporation loss depends on heat rejection and temperature drop.

Blowdown controls dissolved solids concentration.

Drift is small but measurable.

0.001% – 0.02% of circulation rate (with drift eliminators)

For modern cooling water tower design, drift loss is often assumed as 0.02%.

Cooling Tower Makeup Water=Evaporation+Blowdown+Drift

| Item | Value |

|---|---|

| Cooling tower water flow rate | 500 m³/h |

| Temperature difference (ΔT) | 5°C |

| Evaporation loss | 2.5 m³/h |

| Cycles of concentration | 5 |

| Blowdown loss | 0.63 m³/h |

| Drift loss | 0.1 m³/h |

| Total makeup water | ≈ 3.23 m³/h |

This value represents the required cooling tower makeup water to maintain stable operation.

A cooling tower make up water valve regulates water supply based on basin level.

A cooling tower makeup water float valve automatically opens or closes according to cooling tower water level.

Proper cooling tower water level control:

Prevents pump cavitation

Avoids overflow and water waste

Ensures stable condenser water temperature

Mach Cooling Tower integrates reliable water level control systems into its cooling towers.

Typical parameters include:

TDS

Hardness

Chloride

pH

Suspended solids

Meeting cooling tower makeup water quality standards helps prevent scaling, corrosion, and biological growth.

A common rule:

Makeup water ≈ 1.2–1.5 × evaporation loss

This simplified method is useful during preliminary cooling water tower design.

Increase cycles of concentration

Improve drift eliminator efficiency

Optimize blowdown control

Use automated water management systems

Good cooling tower water management improves:

Water efficiency

Operating cost

Environmental sustainability

Mach Cooling Tower (https://www.machcooling.com/) designs advanced cooling systems with:

Optimized cooling tower water flow rate

Accurate water loss calculation

Efficient makeup water valve and level control

Proven water conservation features

Their engineering approach ensures reliable performance in both industrial and HVAC applications.

Understanding how to calculate makeup water for a cooling tower is essential for controlling cooling tower water consumption, improving water efficiency, and maintaining stable condenser water operation. By accounting for evaporation, blowdown, and drift losses, operators can accurately determine makeup water demand and optimize system performance.

With professionally engineered systems from Mach Cooling Tower, facilities can achieve reliable cooling, reduced water usage, and long-term operational savings.