We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-01-04 Origin: Site

“How often should cooling tower cleaning be done?”This question comes up again and again in industrial plants, commercial buildings, and HVAC facilities. And honestly, it’s a good question—because getting the answer wrong can quietly drain energy, shorten equipment life, and even create health risks.

The short answer? There is no one-size-fits-all schedule.

The smart answer? Cleaning frequency should be based on system type, water quality, operating conditions, and equipment design.

In this complete guide, we’ll explain everything in plain English—how often cooling tower cleaning should be done, what factors affect the schedule, what warning signs to watch for, and why choosing a well-designed cooling tower from manufacturers like MACH Cooling can significantly reduce cleaning frequency and maintenance costs.

Cooling towers work in a tough environment: heat, water, air, and contaminants all meet in one place. That makes them efficient—but also vulnerable.

Cleaning frequency matters because it directly affects performance, cost, safety, and reliability.

A dirty cooling tower is like a clogged radiator in a car. Heat transfer efficiency drops, fans and pumps work harder, and energy bills quietly climb. Even a thin layer of scale or biofilm can reduce heat transfer by 5–15%.

When cleaning is delayed, scale buildup and biological fouling accelerate corrosion and mechanical wear. Over time, this leads to premature failure of fill, pumps, heat exchangers, and piping.

Warm water combined with organic matter creates the perfect environment for bacteria, including Legionella. Inadequate cleaning increases the risk of airborne contamination and regulatory trouble.

Instead of relying on guesswork, cleaning frequency should be based on real operating conditions.

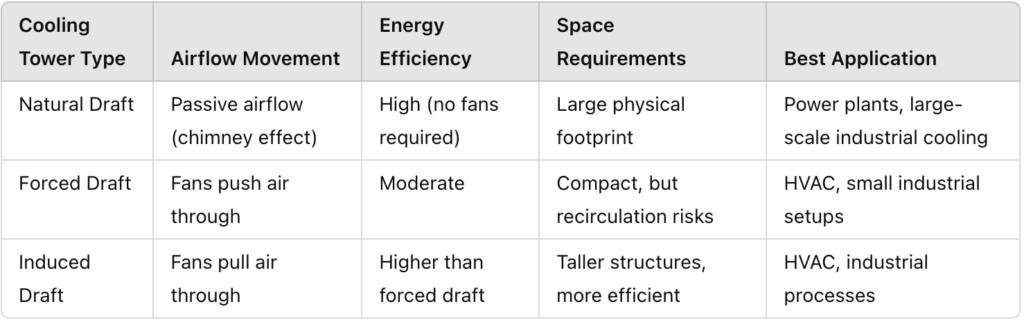

Open circuit cooling towers are exposed to ambient air and typically require more frequent cleaning

Closed circuit cooling towers stay cleaner but still need periodic inspection and internal coil cleaning

Hard water promotes scale formation. Poor water treatment encourages algae and bacterial growth. Simply put: the worse the water, the more often you need to clean.

Dusty factories, coastal areas, heavy pollen regions, and high-pollution zones all accelerate fouling and shorten cleaning intervals.

A cooling tower running 24/7 under heavy thermal load will foul much faster than a system operating intermittently.

While every system is different, industry experience provides reliable baseline guidelines.

Common in offices, hotels, and commercial buildings:

Inspection: monthly

Cleaning: every 6 months

Used in manufacturing, power generation, and process cooling:

Inspection: biweekly or monthly

Cleaning: quarterly

Hospitals, data centers, pharmaceutical plants:

Inspection: weekly

Cleaning: quarterly or as needed

Sometimes the calendar doesn’t matter—your system tells you it’s time.

Watch for these warning signs:

Reduced cooling performance

Rising energy consumption

Visible algae or slime

Strong odors from the basin

Clogged spray nozzles or strainers

Ignoring these signs is like ignoring a “check engine” light.

Many facilities still rely on annual cleaning, but that approach is often risky.

Cooling towers that shut down seasonally should be cleaned:

Before startup

After shutdown

Systems running continuously require scheduled cleaning regardless of season. Fouling doesn’t stop just because the weather changes.

Because they directly contact air, open cooling towers typically require:

More frequent inspections

Shorter cleaning intervals

Closed systems remain cleaner overall but still require:

Coil inspection

Periodic chemical cleaning

Manufacturers such as MACH Cooling design both systems with maintenance access in mind, reducing cleaning time and labor.

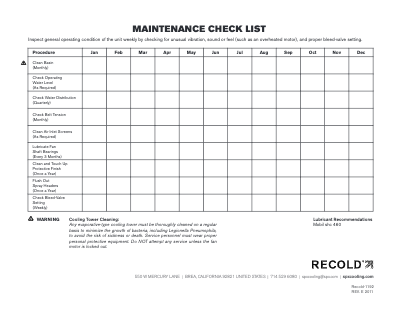

Best for removing sludge, debris, and visible buildup. Usually performed during scheduled shutdowns.

Targets scale, biofilm, and bacteria in hard-to-reach areas. Frequency depends on water chemistry and treatment effectiveness.

The best strategy combines both—just like brushing and flossing. One without the other isn’t enough.

Yes, cleaning too often can be a problem.

Under-cleaning leads to inefficiency, corrosion, and health risks

Over-cleaning increases downtime, chemical exposure, and wear on materials

The goal is balance—not extremes.

In many regions, cooling tower maintenance is no longer optional. Regulations increasingly require:

Documented inspection schedules

Cleaning and disinfection records

Legionella risk management

A clear, consistent cleaning plan helps ensure compliance and protects your organization.

Not all cooling towers are created equal. Design plays a major role in how often cleaning is required.

MACH Cooling focuses on:

Smooth internal surfaces that resist fouling

Easy-access basins and fill media

Durable materials that withstand repeated cleaning

Good design means less buildup, longer intervals between cleanings, and lower lifecycle costs.

To determine the right cleaning frequency:

Analyze water quality

Monitor system load and operating hours

Perform regular inspections

Adjust cleaning schedules based on real data

Work with experienced manufacturers and service providers

Proactive planning always beats reactive repairs.

So, how often should cooling tower cleaning be done?

As often as your system needs—based on conditions, not assumptions.

With proper monitoring, smart scheduling, and high-quality equipment from manufacturers like MACH Cooling, you can reduce unnecessary cleaning, protect system performance, and control long-term costs.

A clean cooling tower runs cooler, lasts longer, and costs less to operate. And that’s a routine worth maintaining.