We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-12-30 Origin: Site

If you’ve ever looked up at the roof of a large office building or hospital and noticed a tall structure releasing a light white plume, you were probably looking at a cooling tower. While it may seem mysterious at first glance, a cooling tower is actually one of the most important components in large HVAC systems.

So, how does a cooling tower work in HVAC, and why is it so widely used? Let’s walk through the process step by step in a clear, human, and practical way—no engineering degree required.

In HVAC systems, cooling towers act like the system’s heat exit door. Air conditioners and chillers collect heat from indoor spaces, but that heat has to go somewhere. Cooling towers provide a reliable and energy-efficient way to release it into the atmosphere.

Without cooling towers, large HVAC systems would consume much more electricity and struggle to maintain stable temperatures.

Cooling doesn’t eliminate heat—it simply moves it. In large buildings, the amount of heat generated by people, equipment, lighting, and sunlight is enormous. Chillers absorb this heat, but their efficiency depends heavily on how easily that heat can be rejected.

Cooling towers use evaporative cooling, which is far more efficient than relying on air alone. This is why cooling towers are essential in commercial and industrial HVAC applications.

A cooling tower is a heat rejection device that removes heat from warm water by allowing a small portion of the water to evaporate.

Compared with air-cooled systems, cooling towers:

Handle much larger cooling loads

Use less electrical energy

Perform better in hot climates

That’s why they are the preferred choice for large HVAC systems.

The secret behind cooling towers is simple: evaporation.

When water evaporates, it absorbs heat from its surroundings. Cooling towers take advantage of this natural process to remove heat from condenser water efficiently.

Large fans move air through the tower, increasing the rate of evaporation and carrying heat away.

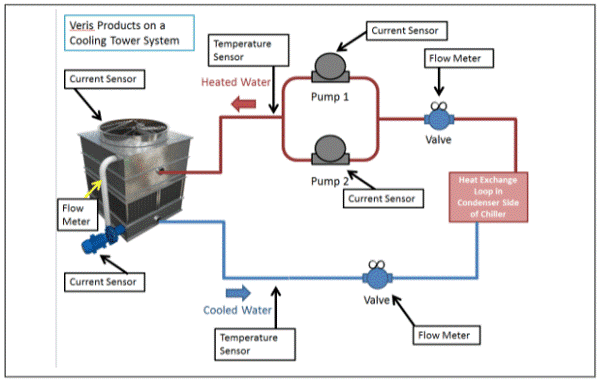

Although cooling towers look simple from the outside, several key components work together inside.

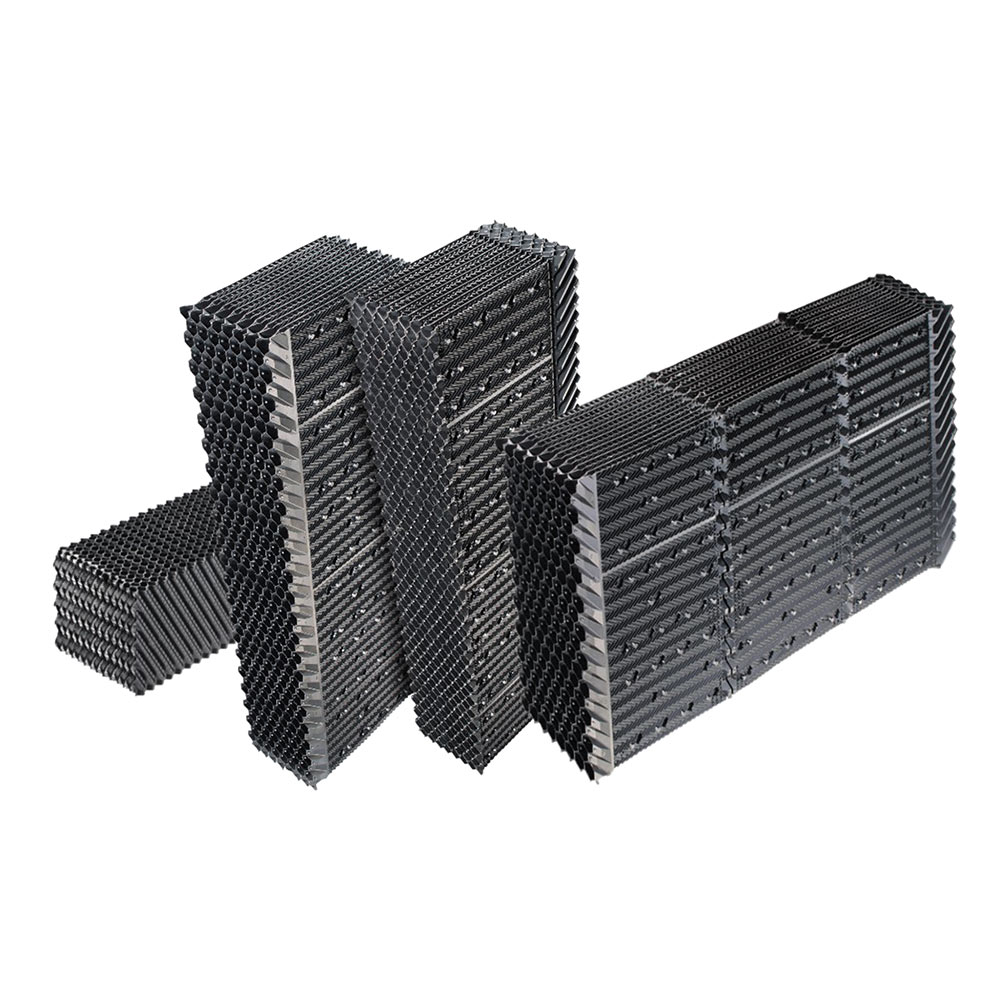

Fill material increases the contact surface between water and air, maximizing heat transfer.

Fans control airflow through the tower and directly affect cooling capacity.

Spray nozzles distribute warm water evenly over the fill.

Drift eliminators prevent water droplets from escaping with the exhaust air, reducing water loss.

Let’s follow the cooling process from start to finish.

Warm condenser water from the chiller flows into the top of the cooling tower.

As water flows downward, air moves upward or across it. A small amount of water evaporates, carrying heat away.

The cooled water collects in the basin and is pumped back to the chiller to repeat the cycle.

Open cooling towers allow direct contact between air and water. They are:

Highly efficient

Common in commercial HVAC

Cost-effective for large buildings

However, they require proper water treatment to control scale and biological growth.

Closed cooling towers keep process water inside coils, isolating it from air exposure. Benefits include:

Cleaner circulating water

Reduced maintenance

Longer equipment life

Cooling towers don’t work alone—they are closely tied to chillers.

The chiller absorbs heat from the building, while the cooling tower rejects that heat outdoors. Think of it like a relay race: the chiller passes the heat to the cooling tower, and the cooling tower carries it across the finish line.

Lower condenser water temperatures allow chillers to operate more efficiently.

Because evaporative cooling uses less electricity, overall energy consumption drops significantly.

Cooling towers are widely used in:

Office buildings

Hospitals and healthcare facilities

Airports and shopping centers

Data centers

Universities and campuses

Mineral buildup reduces heat transfer efficiency and must be controlled with proper water treatment.

Algae and bacteria can form if maintenance is neglected. Regular inspection and treatment are essential.

At Mach Cooling (https://www.machcooling.com/), HVAC cooling towers are designed with efficiency, durability, and reliability in mind. Key advantages include:

High heat rejection performance

Low drift rates

Energy-saving fan systems

Custom designs for commercial HVAC projects

Do all HVAC systems need a cooling tower?

No. Small systems may use air-cooled units, but large systems benefit greatly from cooling towers.

Are cooling towers environmentally friendly?

Yes. They rely on natural evaporation rather than energy-intensive cooling methods.

So, how does a cooling tower work in HVAC?

In simple terms:

HVAC systems collect unwanted heat

Chillers transfer that heat to water

Cooling towers release the heat into the air using evaporation

This proven and energy-efficient process makes cooling towers a cornerstone of large HVAC systems. When paired with high-quality engineering—such as the solutions offered by Mach Cooling—cooling towers help deliver reliable cooling, lower operating costs, and long-term system performance.