We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-12-22 Origin: Site

Cooling towers play a critical role in industrial processes and HVAC systems by efficiently removing excess heat from water and releasing it into the atmosphere. From large commercial buildings to power plants and manufacturing facilities, cooling towers ensure stable system performance, energy efficiency, and equipment longevity.

In this article, we explain how a cooling tower works, explore different cooling tower types and working principles, and introduce reliable solutions from Mach Cooling Tower (https://www.machcooling.com/), a professional manufacturer of industrial and HVAC cooling towers.

A cooling tower is a heat rejection device that cools warm circulating water by transferring heat to ambient air. This process mainly relies on evaporation, although some systems use air convection without water loss.

Cooling towers are widely used in:

HVAC air conditioning systems

Industrial process cooling

Power generation and petrochemical plants

Data centers and refrigeration systems

By reducing water temperature, cooling towers allow the system to reuse water continuously, improving operational efficiency and reducing overall energy consumption.

Different applications require different cooling solutions. Understanding cooling tower types helps engineers select the most efficient and economical system.

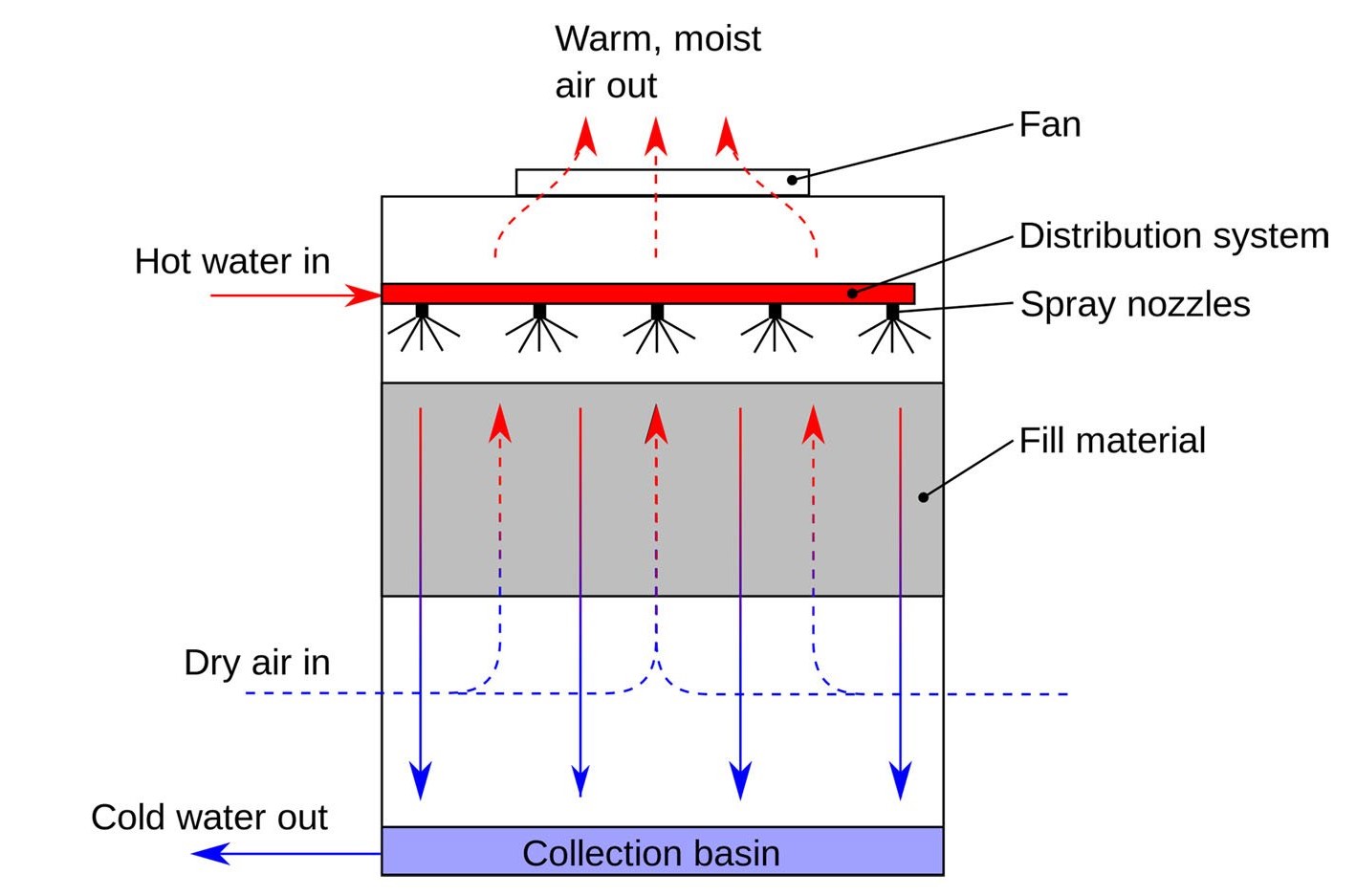

In open circuit cooling towers, hot water is sprayed over fill media while air flows through the tower. A small portion of water evaporates, removing heat from the remaining water.

Key characteristics:

High cooling efficiency

Direct contact between water and air

Commonly used in industrial HVAC systems

This type includes traditional BAC cooling tower designs widely used in commercial and industrial projects.

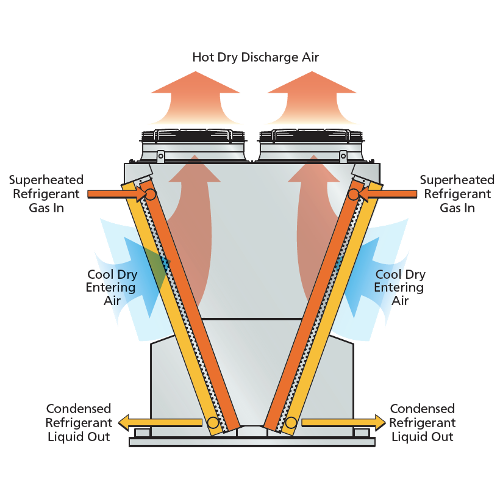

A closed type cooling tower, also known as a closed circuit cooling tower, closed cooling tower, or closed cell cooling tower, isolates process fluid from the outside air.

How it works:

Process fluid flows inside a sealed coil

Spray water evaporates over the coil surface

Heat is transferred without contaminating the process fluid

Advantages:

Clean and stable water quality

Lower maintenance requirements

Ideal for industrial processes and HVAC cooling tower types

Mach Cooling specializes in high-efficiency closed circuit cooling tower solutions for demanding applications.

A dry type cooling tower removes heat using air only, without evaporation. Heat exchangers transfer thermal energy directly to the air.

Benefits:

Zero water consumption

Environmentally friendly

Suitable for water-scarce regions

Dry cooling towers are often selected when water conservation or strict environmental regulations are required.

A round cooling tower features a cylindrical structure that enhances airflow distribution and structural stability. It is compact, efficient, and easy to install.

A square cooling tower uses a rectangular layout, making it ideal for modular installation, large cooling capacities, and convenient maintenance.

An FRP cooling tower is constructed from fiberglass-reinforced plastic, offering:

Excellent corrosion resistance

Long service life

Lightweight but strong structure

Mach Cooling Tower manufactures both round cooling towers and square cooling towers using premium FRP materials to ensure durability and performance.

Hot water enters the cooling tower from the system or process

Water distribution system sprays water evenly over the fill or coil

Airflow interaction occurs via axial or centrifugal fans

Heat is removed through evaporation or air convection

Cooled water collects in the basin and returns to the system

Evaporation removes heat by converting liquid water into vapor. Even a small amount of evaporated water can dissipate a large quantity of heat, making evaporative cooling towers extremely efficient.

Cooling towers are essential components of HVAC systems, especially for:

Chiller condenser cooling

Large commercial buildings

District cooling plants

Closed circuit cooling towers are particularly popular in HVAC applications due to their clean operation and stable heat exchange performance.

| Cooling Tower Type | Cooling Method | Typical Application | Key Advantage |

|---|---|---|---|

| Open / Wet (BAC) | Evaporation | Industrial HVAC | High efficiency |

| Closed circuit cooling tower | Coil + spray evaporation | HVAC & process cooling | Clean water loop |

| Dry type cooling tower | Air convection only | Water-limited areas | No water loss |

| Round cooling tower | Evaporative | Compact installations | Space saving |

| Square cooling tower | Evaporative | Large capacity systems | Easy maintenance |

| FRP cooling tower | Structural material | Corrosive environments | Long service life |

Mach Cooling Tower (https://www.machcooling.com/) is a professional manufacturer offering:

Closed circuit cooling towers

Open and dry type cooling towers

FRP round and square cooling towers

Customized HVAC and industrial cooling solutions

With advanced manufacturing technology and strict quality control, Mach Cooling delivers reliable, energy-efficient cooling tower systems to customers worldwide.

Understanding how a cooling tower works is essential for selecting the right cooling solution. Whether it is an open cooling tower, closed type cooling tower, dry type cooling tower, or specialized HVAC cooling tower types, each design serves specific operational needs.

By choosing high-quality products from Mach Cooling Tower, users can achieve efficient heat rejection, reduced operating costs, and long-term system reliability.