We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-12-30 Origin: Site

In large commercial buildings, industrial plants, data centers, and power facilities, cooling is not handled by a single piece of equipment. Instead, it’s a carefully coordinated system where different components work together like gears in a machine. At the heart of many high-capacity cooling systems are the cooling tower and the chiller.

So how does a cooling tower and chiller work together? Why are they so often paired, and what makes this combination so efficient?

Let’s walk through the process step by step—in simple language, without unnecessary technical jargon.

Think of heat like unwanted garbage inside a building or process. The chiller is the one that collects the garbage, while the cooling tower is the one that takes it outside and gets rid of it.

On their own, each system has a purpose. Together, they form one of the most effective and energy-efficient cooling solutions available today.

The main reason these two systems are paired is efficiency.

Chillers are excellent at absorbing heat from indoor spaces or industrial processes. However, once that heat is absorbed, it must be rejected somewhere. Doing this with air alone—especially at large capacities—would consume enormous amounts of energy.

Cooling towers solve this problem by using water evaporation, a natural and highly efficient way to release heat into the atmosphere. This teamwork significantly reduces operating costs and improves system reliability.

A chiller is a mechanical system designed to remove heat from a liquid, usually water, and deliver that chilled water to air-conditioning units or industrial equipment.

Inside a chiller:

Warm water absorbs heat from the building or process.

That heat is transferred to a refrigerant inside the chiller.

The refrigerant carries the heat to the condenser section.

There are two main types:

Air-cooled chillers, which reject heat directly to the air

Water-cooled chillers, which rely on cooling towers

Water-cooled chillers are more efficient and are the focus of this article.

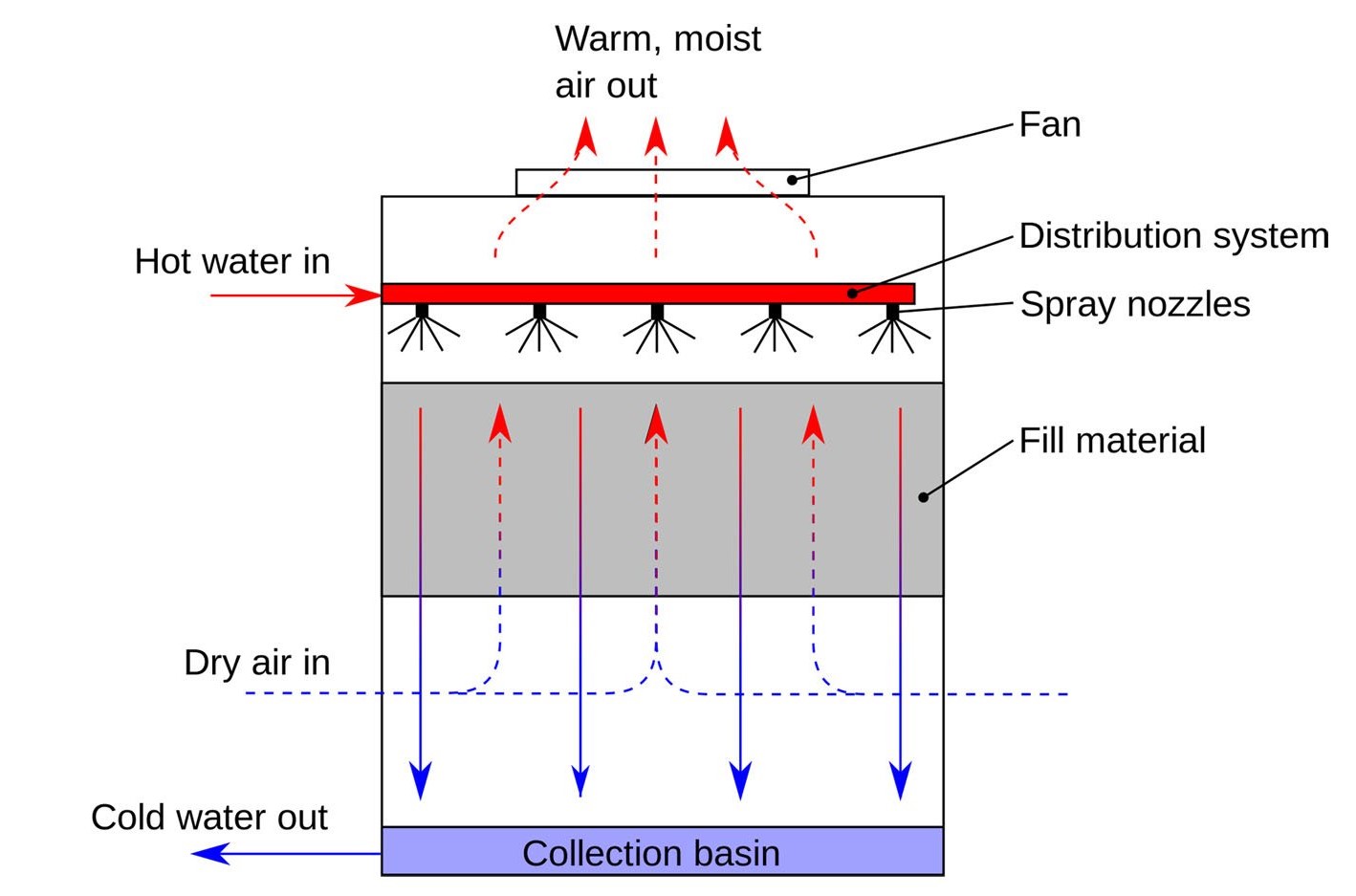

A cooling tower is a heat-rejection device that removes heat from warm water by allowing a small portion of that water to evaporate.

Warm condenser water enters the cooling tower and is distributed over fill material. As air moves through the tower, evaporation occurs, carrying heat away. The cooled water is then reused in the system.

Open cooling towers allow direct contact between water and air

Closed cooling towers keep process fluid inside coils, isolating it from air

Both types can work with chillers, depending on application needs.

The chilled water loop is the part of the system responsible for cooling the building or process.

In this loop:

Chilled water flows from the chiller to air handlers or heat exchangers

The water absorbs heat

Warm water returns to the chiller to be cooled again

This loop is completely separate from the cooling tower.

The condenser water loop connects the chiller and the cooling tower.

In this loop:

The chiller transfers heat to condenser water

Hot condenser water flows to the cooling tower

The cooling tower releases heat to the atmosphere

Cooled water returns to the chiller

This continuous circulation is what allows the chiller to keep operating efficiently.

Let’s put it all together.

Chilled water absorbs heat from indoor air or industrial equipment inside the chiller’s evaporator.

The chiller moves that heat from the refrigerant to the condenser water loop.

The cooling tower releases the heat into the atmosphere using evaporation.

The cooled condenser water then returns to the chiller, and the cycle repeats.

Water-cooled chiller systems paired with cooling towers offer several advantages:

Higher energy efficiency

Better performance in hot climates

Lower long-term operating costs

This is why they are widely used in large-scale applications.

Evaporative cooling removes heat with far less electricity than air-based cooling alone.

Cooling towers help maintain low condenser temperatures, which improves chiller efficiency and extends equipment life.

Cooling tower and chiller systems are commonly found in:

Office buildings and shopping centers

Hospitals and airports

Data centers

Manufacturing plants

Power generation facilities

Poor water treatment can reduce heat transfer efficiency.

This can be caused by insufficient airflow, high ambient temperatures, or undersized cooling towers.

Proper design and maintenance are essential.

At Mach Cooling (https://www.machcooling.com/), cooling towers are engineered to integrate seamlessly with water-cooled chillers. Key advantages include:

High-efficiency heat rejection

Low drift and water loss

Durable industrial construction

Custom solutions for HVAC and industrial applications

Can a water-cooled chiller operate without a cooling tower?

No. A cooling tower is essential for rejecting heat.

Is this system suitable for small buildings?

It’s best for medium to large cooling loads.

So, how does a cooling tower and chiller work together?

In simple terms:

The chiller absorbs heat

The cooling tower rejects heat

Together, they create an efficient, reliable cooling system

Like a well-coordinated relay team, each component plays its role at the right time. When properly designed and installed, a cooling tower and chiller system delivers powerful cooling performance with excellent energy efficiency.

For dependable, high-performance cooling tower solutions, Mach Cooling provides systems designed to maximize chiller efficiency and long-term reliability.