We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-01-22 Origin: Site

In any cooling tower system, the fan, motor, and gearbox work together like a well-rehearsed orchestra. When one instrument falls out of tune, performance drops, energy consumption rises, and failure becomes only a matter of time. That’s why fan, motor, and gearbox inspection is one of the most critical aspects of cooling tower operation.

This article provides a practical, industry-proven inspection guide used by operators, maintenance teams, and cooling tower manufacturers worldwide. Whether you manage an industrial plant, HVAC system, or power facility, this guide will help you inspect smarter, prevent failures, and extend equipment life.

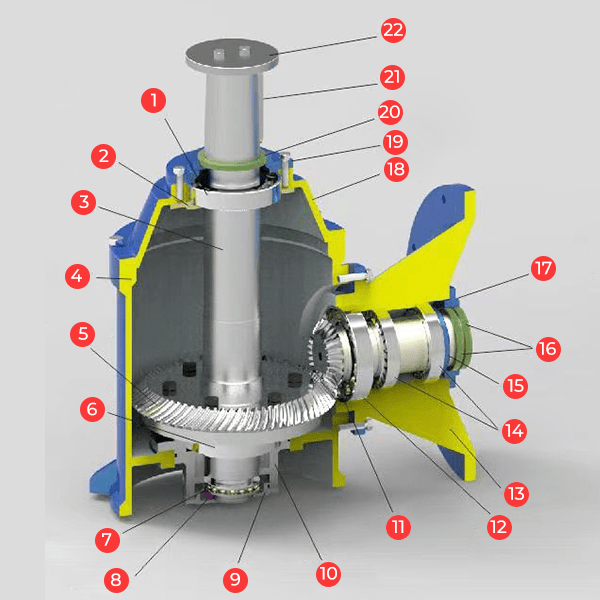

A cooling tower may look like a static structure, but inside it’s constantly in motion. The fan pulls air, the motor delivers power, and the gearbox controls speed and torque. Together, they form the mechanical drive system.

Inspection focuses on:

Mechanical condition

Electrical health

Alignment and balance

Lubrication quality

Early failure indicators

Skipping inspections is like driving a car without checking the oil—everything seems fine until it suddenly isn’t.

Most unexpected cooling tower shutdowns don’t start with structural damage. They start quietly—with vibration, heat, or lubrication problems.

Regular inspection helps you:

Avoid unplanned downtime

Maintain stable airflow and heat rejection

Reduce repair and replacement costs

Improve energy efficiency

Extend the overall service life of the cooling tower

For industrial users, inspection is not a cost—it’s insurance.

Before inspecting individual components, it’s important to understand how they interact.

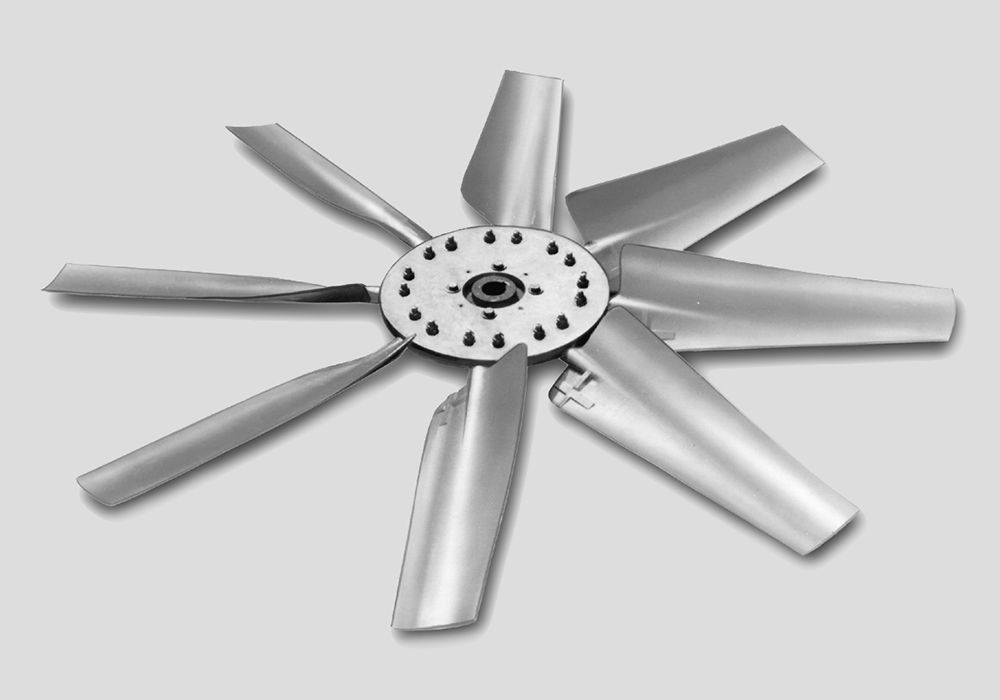

The fan moves air through the tower, enabling evaporation and heat transfer. Any defect in the fan directly reduces cooling performance.

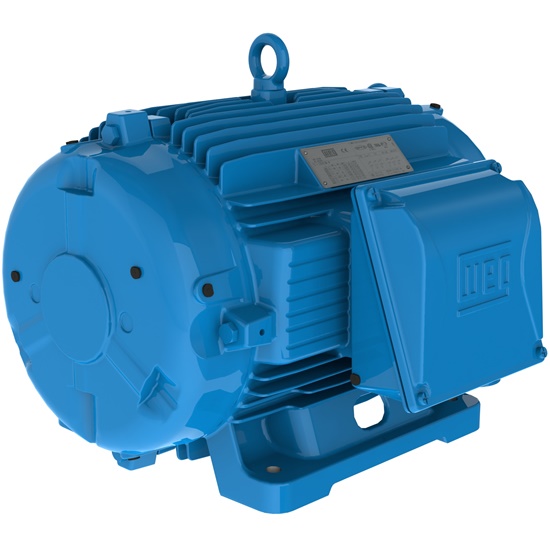

The motor converts electrical energy into mechanical motion. Motors must operate continuously in humid, harsh environments, making inspection essential.

The gearbox adjusts motor speed to the optimal fan RPM while increasing torque. It is one of the most expensive and sensitive components.

Fan-related failures are often mechanical and highly destructive if ignored.

Inspect blades for:

Cracks or fractures

Erosion on leading edges

UV or chemical degradation

Scale or debris buildup

Even small defects can lead to imbalance and vibration.

An unbalanced fan behaves like an off-center flywheel.

Watch for:

Excessive vibration

Uneven blade pitch

Shaft misalignment

Correcting balance early protects bearings, motors, and gearboxes.

Loose or corroded fasteners are a common failure point.

Ensure:

All bolts are torqued correctly

No corrosion at hub connections

No elongation or deformation of bolt holes

Motors usually give warning signs before failure—if you know what to look for.

Check:

Voltage and current balance

Insulation resistance

Terminal tightness

Signs of moisture ingress

Electrical imbalance increases heat and shortens motor life.

Bearings are often the first motor component to fail.

Inspect for:

Grease contamination

Over- or under-lubrication

Abnormal noise or temperature

Common warning signs include:

Burnt insulation smell

Discolored windings

Frequent thermal protection trips

Overheating drastically reduces motor lifespan.

Gearboxes are robust—but unforgiving when neglected.

Oil condition reflects gearbox health.

Inspect:

Oil level

Color and clarity

Presence of metal particles

Water contamination

Milky or dark oil indicates internal problems.

During scheduled shutdowns:

Inspect gear teeth for pitting or scoring

Measure backlash

Check seals and breathers

Unusual noise is never normal.

Grinding, whining, or knocking often points to:

Bearing wear

Gear misalignment

Lubrication failure

A practical inspection schedule includes:

Daily: Visual and audible checks

Monthly: Vibration, temperature, lubrication

Quarterly: Alignment and electrical checks

Annually: Comprehensive mechanical inspection

Leading manufacturers like MACH Cooling often tailor inspection schedules based on cooling tower design, operating hours, and environmental conditions.

Typical issues include:

Fan blade erosion or cracking

Motor bearing wear

Gearbox oil contamination

Loose fasteners

Shaft misalignment

The key advantage of inspection is that most of these problems are easy to fix when found early.

Inspection must always be safe.

Follow best practices:

Lockout/tagout (LOTO)

Use proper PPE

Apply fall protection

Never inspect rotating equipment

Safety is part of professionalism.

In-house inspections handle routine monitoring

Professional inspections provide advanced diagnostics like vibration analysis, oil testing, and laser alignment

A combined approach delivers the best reliability.

A well-designed cooling tower is easier to inspect.

MACH Cooling (https://www.machcooling.com/) supports long-term inspection and maintenance through:

Durable fan and drive system design

Inspection-friendly layouts

High-quality motors and gearboxes

Technical documentation and support

Design-for-maintenance reduces lifecycle cost significantly.

Modern inspection is becoming smarter.

Advanced systems now include:

Online vibration monitoring

Thermal imaging

Oil condition sensors

Predictive maintenance software

These tools shift maintenance from reactive to predictive.

Fan, motor, and gearbox inspection is not optional—it’s essential.

With consistent inspection:

Failures are detected early

Efficiency remains stable

Maintenance costs drop

Equipment life is extended

Supported by experienced manufacturers like MACH Cooling, a disciplined inspection strategy keeps cooling towers reliable, efficient, and ready for long-term operation.