We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-01-20 Origin: Site

When people see a huge white cloud rising from a power station cooling tower, the first reaction is often concern: Is that pollution? Is something being burned? In reality, most of what you see is simply water vapor. Still, emission and plume control in power station cooling towers has become a critical topic as environmental standards tighten and power plants move closer to cities and sensitive ecosystems.

In this article, we’ll break down what cooling tower plumes really are, why emission control matters, and how modern technologies—offered by experienced manufacturers like Mach Cooling—help power stations balance performance, compliance, and sustainability.

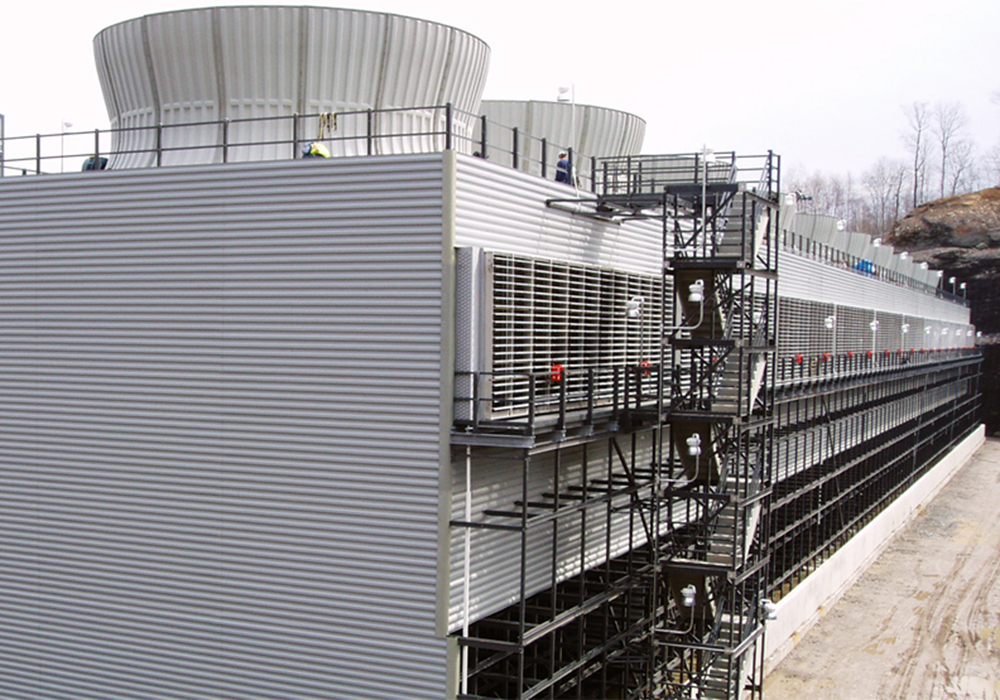

Cooling towers are designed to reject waste heat from power generation processes. As warm circulating water releases heat to the atmosphere, a small portion evaporates. This evaporation is the core of cooling tower efficiency—and also the reason plumes exist.

A cooling tower plume is visible water vapor, formed when warm, moisture-saturated air exits the tower and mixes with cooler ambient air. It’s very similar to the cloud you see when you breathe out on a cold morning. Dramatic? Yes. Dangerous? Usually not.

One of the biggest misconceptions is confusing plume with smoke. Smoke comes from combustion and contains pollutants. A cooling tower plume, by contrast, is mostly condensed water droplets. No burning, no soot—just physics at work.

Even if plumes are harmless, they can still cause problems if not properly controlled.

Large, persistent plumes can alarm nearby communities. In urban or industrial zones, they may affect traffic visibility or raise unnecessary environmental concerns.

Under certain conditions, plumes can contribute to:

Fogging near roads

Icing on nearby structures in cold climates

Mineral deposition from drift

These secondary effects make emission control a serious engineering requirement, not just an aesthetic choice.

Not all cooling tower emissions are the same. Understanding the differences helps engineers choose the right control strategy.

This is the most visible emission and the main cause of plumes. While environmentally benign, it is often regulated due to visibility and microclimate concerns.

Drift occurs when tiny water droplets are carried out of the cooling tower with exhaust air. These droplets may contain dissolved minerals or treatment chemicals, making drift control essential.

Without proper water treatment, cooling tower systems can harbor biological growth or carry trace chemicals. Modern emission control strategies always go hand in hand with effective water management.

Power stations operate under strict environmental frameworks. Emission and plume control is often required to meet:

Drift loss limits (typically below 0.002% of circulating water)

Local plume visibility rules

Environmental impact assessment conditions

Failing to comply can mean fines, operational restrictions, or even shutdowns.

Fortunately, technology has come a long way. Today’s plume control solutions are more efficient, flexible, and cost-effective than ever before.

These systems reduce visible plumes by reheating saturated exhaust air or condensing moisture before discharge. They are widely used in cold climates and urban installations.

Hybrid cooling towers combine dry and wet sections. During colder months, the dry section preheats the exhaust air, significantly reducing or eliminating visible plume formation.

Dry cooling systems eliminate plume entirely by avoiding evaporation. While effective, they usually involve higher capital costs and can be less efficient in hot climates.

Drift eliminators may not look impressive, but they play a huge role in emission control.

Modern drift eliminators use multi-pass blade geometry to capture microscopic droplets before they escape the tower. High-quality designs can reduce drift loss to less than 0.001%.

For power stations, drift eliminators must maintain performance over long operating cycles, resisting fouling, corrosion, and UV exposure.

Emission control doesn’t rely on a single component—it’s built into the entire cooling tower design.

Taller towers improve plume dispersion, while optimized airflow reduces droplet carryover. It’s a classic case of smart geometry solving real-world problems.

Uniform water distribution across the fill prevents localized saturation zones that intensify plume formation.

You can’t talk about emissions without talking about water quality.

Proper water treatment reduces solids, prevents biological growth, and minimizes chemical carryover. This protects not only the environment but also plant personnel and surrounding communities.

Not every power station can install a brand-new cooling tower. Fortunately, many emission and plume control improvements can be retrofitted.

Common upgrades include:

High-efficiency drift eliminators

Hybrid plume abatement modules

Improved water distribution systems

These solutions extend the life of existing assets while improving compliance.

As a professional cooling tower manufacturer, Mach Cooling (https://www.machcooling.com/) provides power station cooling tower solutions with advanced emission and plume control technologies.

With a strong engineering focus, Mach Cooling offers:

Customized plume abatement designs

Low-drift cooling tower configurations

Compliance-ready systems for global power projects

Their solutions are designed to meet strict environmental standards without compromising thermal performance.

In cold regions and densely populated areas, plume control is often mandatory. Hybrid and plume-abated cooling towers are now standard choices for modern thermal and nuclear power stations.

The future of plume control is smart, digital, and sustainable.

Emerging trends include:

Real-time drift monitoring

AI-based plume prediction

Water-saving and low-carbon cooling tower designs

Emission control is evolving from a regulatory obligation into a strategic advantage.

Emission and plume control in power station cooling towers is about more than reducing visible vapor. It’s about environmental responsibility, regulatory compliance, and public trust.

With advanced engineering, smart design, and experienced manufacturers like Mach Cooling, power stations can achieve efficient heat rejection while minimizing environmental impact. In doing so, they don’t just manage plumes—they help build a cleaner, more sustainable energy future.