We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-01-09 Origin: Site

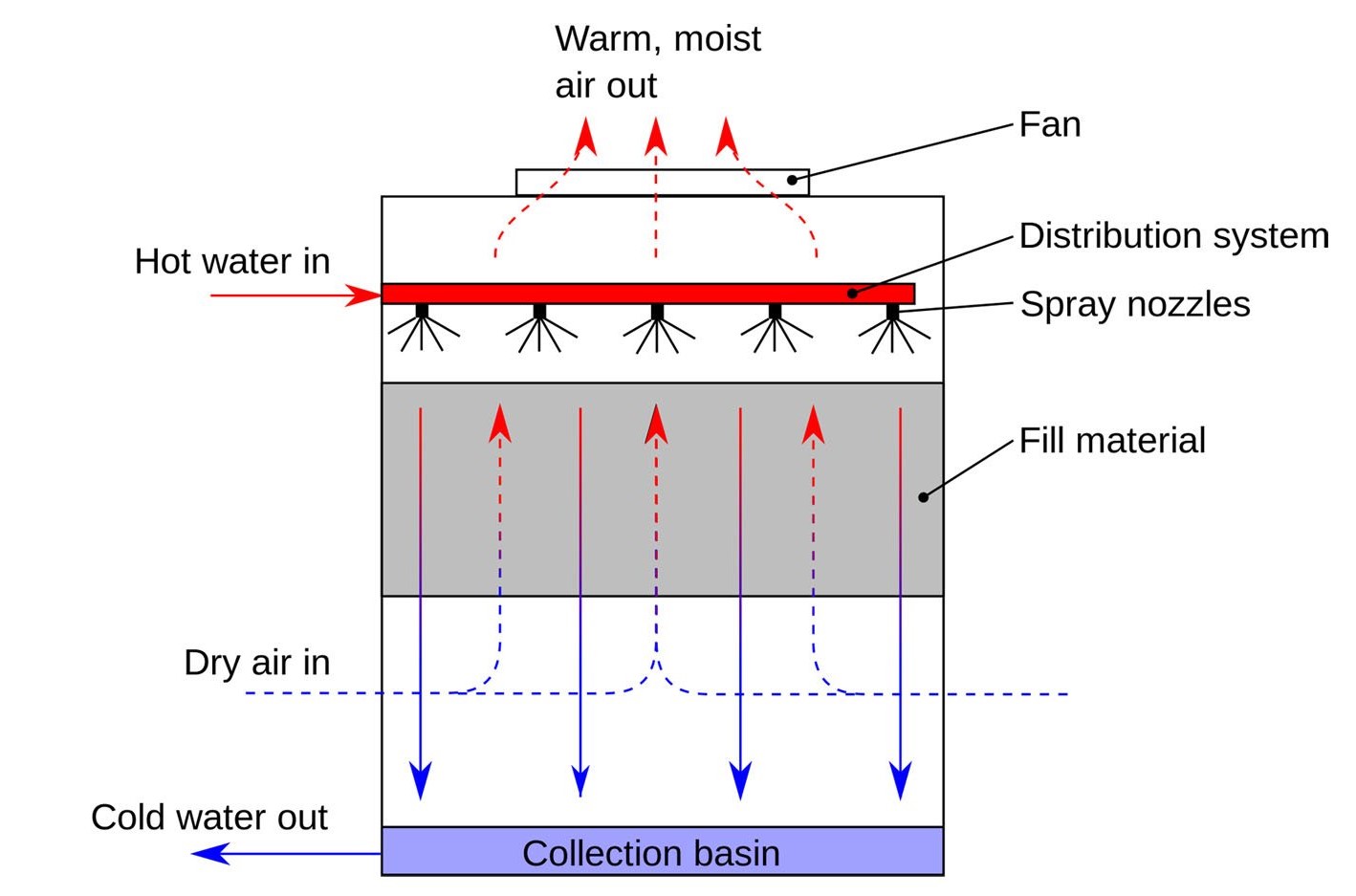

If you think a cooling tower is just a big fan blowing air over water, think again. The real magic happens inside—and the unsung hero of that magic is the cooling tower fill. Without properly designed and maintained fill, even the most powerful fan can’t perform efficiently.

The fill is where heat transfer actually occurs. It maximizes water-to-air contact, allowing hot water from the system to cool effectively. That’s why manufacturers like Mach Cooling (https://www.machcooling.com/) emphasize selecting the right fill and maintaining it properly.

Cooling tower fill is a material installed inside the tower to increase the surface area for water-air contact. Think of it as the “sponge” of the cooling system. It slows down water flow, spreads it evenly, and ensures maximum evaporation and heat transfer.

There are two main types of fill:

Splash fill breaks water into droplets. As water splashes over layers of material, the surface area increases and evaporation improves. Splash fill is robust and ideal for systems with poor water quality.

Film fill spreads water into thin sheets over vertical or corrugated surfaces. This creates a huge surface area for heat transfer and is more efficient, though it’s more sensitive to fouling.

The core function of fill is heat exchange. Hot water flows over the fill surfaces, while air passes through, transferring heat from water to air. The greater the surface area the fill provides, the better the cooling.

Even water distribution across the fill ensures uniform cooling. Poor distribution creates hot spots and reduces overall efficiency.

Well-designed fill improves thermal efficiency. Correct spacing, thickness, and material selection can dramatically enhance heat transfer.

Proper fill reduces scaling, fouling, and uneven wear. This extends the life of the tower and reduces maintenance costs.

PVC is lightweight, corrosion-resistant, and durable. Modern plastic fills are designed for easy cleaning and maximum surface area.

Wood fills are traditional, offering good heat transfer but requiring more maintenance. Composite materials combine durability with high performance, ideal for demanding systems.

Debris, minerals, and biofilm can accumulate on the fill, reducing water-air contact and overall cooling efficiency.

Regular inspections, high-pressure washing, and chemical treatment are standard. Manufacturers like Mach Cooling provide guidance on safe cleaning techniques that preserve fill integrity.

High-efficiency fill maximizes evaporation and heat transfer, requiring less water circulation for the same cooling output.

Efficient fills reduce the workload on fans and pumps, saving energy and cutting operating costs.

Good fill design helps maintain consistent outlet water temperature, preventing overheating in downstream equipment.

Fill design also affects airflow resistance. Optimizing the fill minimizes unnecessary fan power usage.

Choose fill based on system size, water flow rate, and temperature range. Material compatibility and durability are key factors.

Water quality, maintenance frequency, and environmental conditions should guide selection to ensure optimal performance.

Modern fills feature optimized geometries that increase contact area while minimizing pressure drop.

New materials reduce environmental impact and improve recyclability without sacrificing performance.

Mach Cooling (https://www.machcooling.com/) designs fills that balance efficiency, durability, and ease of maintenance. Their team customizes solutions based on water quality, system capacity, and environmental conditions to maximize cooling tower performance.

The cooling tower fill might seem like a small component, but it’s arguably the most important part of a cooling tower. From enhancing heat transfer and energy efficiency to reducing maintenance and extending system life, fill is at the heart of every cooling tower’s performance.

Choosing the right fill, maintaining it properly, and partnering with experienced manufacturers like Mach Cooling ensures your cooling tower operates at peak efficiency for years to come.

Next time you look at a cooling tower, remember: the fill is the true powerhouse behind the cool.