We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-01-21 Origin: Site

Cooling towers may look like giant chimneys puffing steam into the sky, but they’re actually the silent heroes of industry — especially in power plants, factories, and HVAC systems. They’re responsible for rejecting enormous amounts of heat into the atmosphere as part of thermal cycles.

Understanding cooling efficiency isn’t just technical jargon — it’s an essential piece of the puzzle if you want to cut costs, save energy, and keep your system running smoothly.

In this article, we’ll explore what cooling tower efficiency means, the key factors that impact it, and practical methods to optimize performance — including real-world tips tied to trusted manufacturers like Machcooling, a leader in industrial cooling tower solutions.

In simple terms, cooling tower efficiency measures how well a tower cools the water returned from industrial processes. It’s calculated by comparing the actual heat removed to the theoretical maximum based on environmental wet-bulb temperatures.

A high-efficiency tower delivers water closer to ambient wet-bulb temperatures, reducing stress on chillers and other equipment downstream.

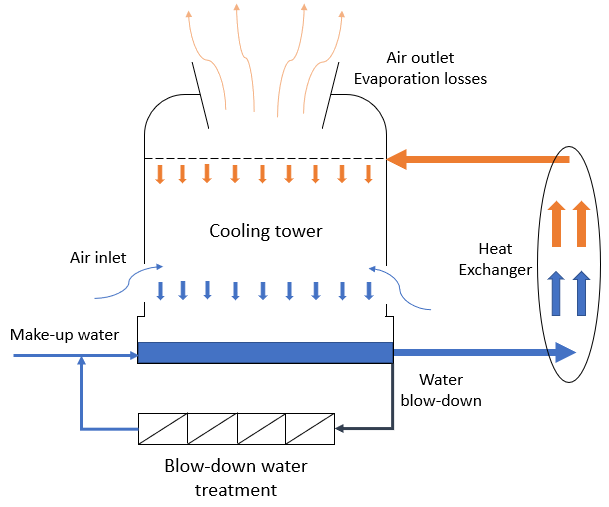

A cooling tower removes heat primarily through evaporation. Hot water from processes is sprayed over fill media, spreading the water into thin films. Air is drawn upward — naturally or via fans — and as it passes over the water, a small portion evaporates, carrying heat away. The cooled water collects at the bottom and returns to the system.

Think about standing in front of a fan with a mist sprayer on a hot day — your sweat evaporates faster, cooling you down. Cooling towers work the same way: heat is removed as water evaporates.

The closer the tower brings water to the wet-bulb temperature, the higher its efficiency. Higher efficiency reduces energy consumption, extends equipment life, and lowers operating costs.

Several variables impact performance. Let’s break them down:

Wet-bulb temperature sets the limit on how cool water can get. High humidity reduces the air’s capacity to absorb moisture, lowering cooling efficiency, while dry air allows better heat transfer.

Air movement is critical. Proper fan selection and placement boost efficiency. External winds can disrupt airflow patterns, reducing performance.

Water must be evenly spread over the fill media. Uneven distribution causes dry spots, limiting heat transfer. Pumps, nozzles, and distribution troughs must be carefully designed.

Counterflow: Air flows opposite to water; generally more efficient but costlier.

Crossflow: Air flows horizontally across falling water; simpler but slightly less efficient.

Fill material surface area affects heat transfer — larger area = better efficiency.

Minerals like calcium and magnesium create scale, reducing heat transfer. Effective water treatment prevents buildup, maintaining efficiency and avoiding damage.

Old or oversized motors and fans waste energy. High-efficiency motors and variable-speed drives optimize airflow and reduce power consumption.

Regular inspections, cleaning, and water quality management ensure consistent performance. Neglect leads to fouling, corrosion, and efficiency loss.

Range: Temperature difference between inlet and outlet water.

Approach: How close outlet water gets to the wet-bulb temperature.

Smaller approach values indicate higher efficiency.

[

\text{Efficiency} = \frac{\text{Range}}{\text{Range + Approach}} \times 100%

]

This formula quantifies performance relative to environmental limits.

High-efficiency fills increase surface area for heat exchange. Improved water distribution ensures even coverage.

Automated controls for fan speed, temperature, and water flow dynamically optimize tower performance.

Prevent scale, corrosion, and microbial growth to maintain consistent heat transfer.

Quarterly inspections and cleaning of mechanical components and fill media ensure consistent operation.

Upgrading to high-efficiency fills, better controls, and water treatment can lead to 10–20% improvements in cooling efficiency. Plants using systems from reliable manufacturers like Machcooling see both energy savings and reduced downtime.

Monitor wet-bulb conditions

Ensure balanced water distribution

Use high-quality fill and fans

Apply water treatment to prevent scaling

Maintain regular service schedules

Cooling towers are precision machines that govern heat rejection. By understanding the key factors and applying optimization methods, you can extend equipment life, reduce costs, and improve sustainability. Choosing the right tower and manufacturer, such as Machcooling, is the first step toward high efficiency.

Q1: What’s the fastest way to improve cooling tower efficiency?

Upgrade fill media and improve water distribution.

Q2: How does humidity affect performance?

High humidity reduces evaporation and lowers cooling efficiency.

Q3: How often should cooling towers be maintained?

Monthly for water checks, quarterly for mechanical inspections.

Q4: Do fan types matter?

Yes — proper fan selection and efficiency are critical.

Q5: Can automation reduce costs?

Yes — control systems dynamically optimize performance, saving energy.

Case Studies: Effective Makeup Water Management in Cooling Towers

What Is The Difference Between Field Erected And Modular Cooling Towers?

How To Define A Cooling Tower Based on Heat Transfer Principles

Noise Reduction And Maintenance Advantages in Cooling Towers

How Smart Monitoring Enhances Cooling Tower Water Efficiency