We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-11-17 Origin: Site

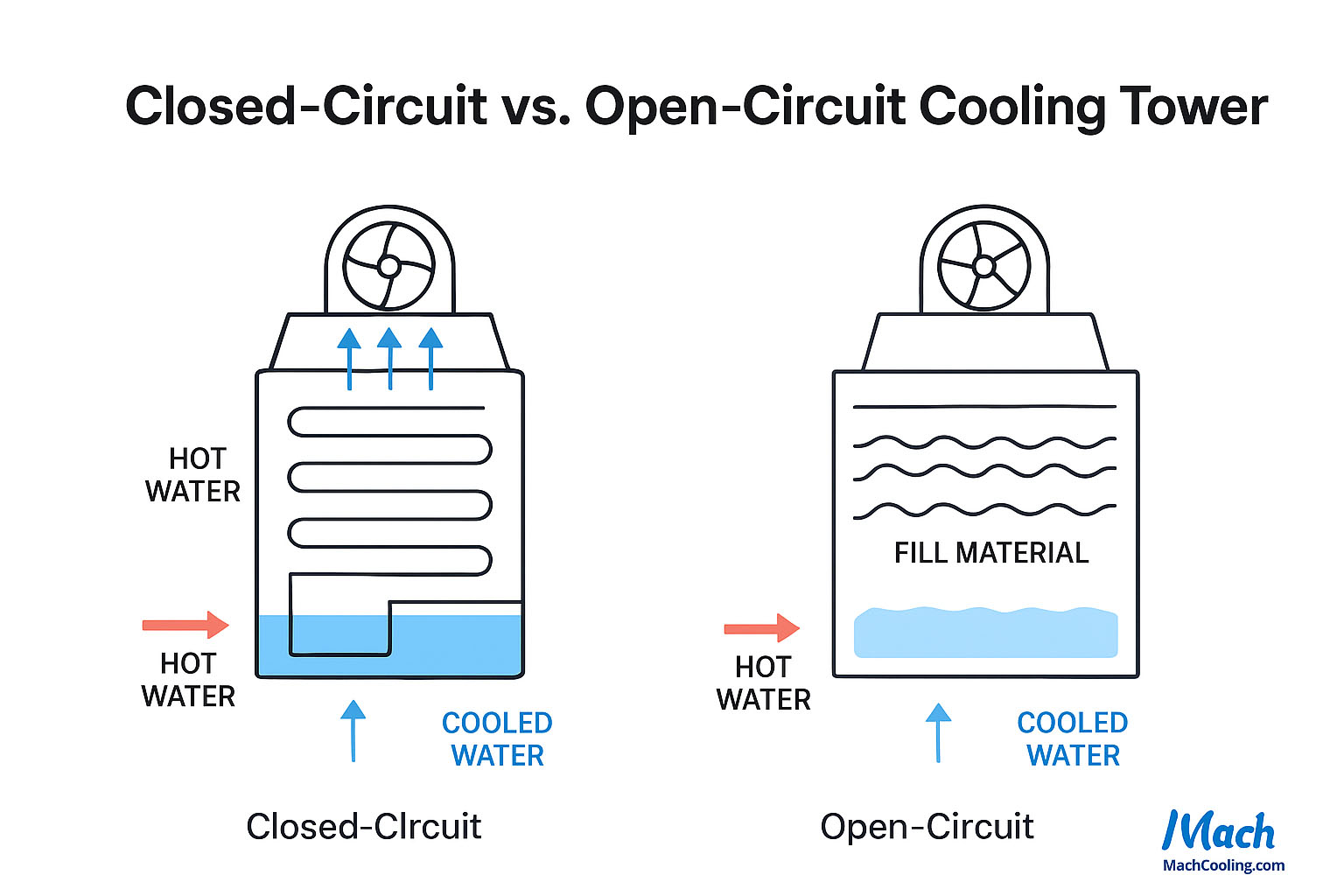

In modern industrial facilities and HVAC systems, cooling towers play a vital role in heat dissipation. Depending on how the circulating water interacts with the air, cooling towers are generally classified into closed-circuit cooling towers and open-circuit cooling towers.

Understanding their structural differences, operating principles, advantages, and limitations is essential for selecting the right equipment. This article provides a comprehensive comparison of both types and explains where each performs best, with reference to Mach Cooling (MachCooling.com), a professional manufacturer of industrial cooling towers.

A cooling tower removes heat from circulating water and releases it into the atmosphere through heat exchange with air. The process includes:

Hot water entering the tower from an industrial or HVAC loop

Heat exchange with air via evaporation and conduction

Cooled water returning to the system

Based on the water–air contact method, cooling towers fall into two primary categories.

The circulating water is sprayed directly into the air stream. Water and air fully contact each other, and cooling mainly occurs through evaporation.

The circulating water flows inside sealed coils (typically copper or stainless steel). External spray water cools the coil surface, but the process water does not contact the air, reducing contamination and corrosion.

Spray system: Sprays hot water onto fill media

Fill media: Increases water–air contact area for efficient evaporation

Fan / air passage: Ensures proper ventilation (counterflow or crossflow designs)

Water basin: Collects cooled water

Closed heat-exchange coils: Carry the process water inside sealed tubing

Spray system: Sprays water over coil surfaces for improved heat exchange

Fan system: Drives airflow across the coil and spray water

Water basin: Recycles spray water

Evaporative cooling removes large amounts of heat

Direct air–water contact enhances thermal performance

Sensible heat transfer through coil walls

Evaporative cooling occurs on the coil’s outer surface

Process water stays clean due to a closed-loop design

Open-Circuit: Water is exposed to air—dust, debris, microbiological growth may occur.

Closed-Circuit: Water remains sealed inside coils, significantly reducing corrosion, fouling, and contamination risk.

Mach Cooling (MachCooling.com) offers both open- and closed-circuit cooling tower solutions, designed for reliability, energy efficiency, and long service life.

| Factor | Open-Circuit Cooling Tower | Closed-Circuit Cooling Tower |

|---|---|---|

| Outlet temperature | Lower, close to wet-bulb | Slightly higher due to coil resistance |

| Initial investment | Low | Higher |

| Water quality | Easily contaminated | Clean and stable (sealed loop) |

| Maintenance | Higher (fill, water treatment) | Lower (coil cleaning only) |

| Water consumption | Higher | Lower |

| Best environments | Large industrial loads | Clean water or harsh environments |

Large cooling capacity

Lower water consumption

Reliability in dusty outdoor conditions

Hybrid cooling system

Combine closed-circuit (protects system water) + open-circuit (provides strong cooling capacity).

Energy-efficient design

High-efficiency fans, optimized air pathway, VFD control, and advanced spray system.

Full maintenance support

Water treatment plan + routine inspections + long-term warranty service.

Selecting the right cooling tower can significantly improve heat exchange performance, reduce operating costs, and enhance long-term system stability.