We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-01-21 Origin: Site

If there’s one concept that truly defines the performance limit of a cooling tower, it’s the relationship between approach temperature and wet bulb temperature. This relationship explains why a cooling tower can never cool water “as much as we want,” why some designs are much larger and more expensive than others, and why experienced manufacturers always start with wet bulb data before talking about capacity.

Whether you’re an engineer, plant manager, or equipment buyer, understanding this relationship will help you make smarter decisions—technically and financially.

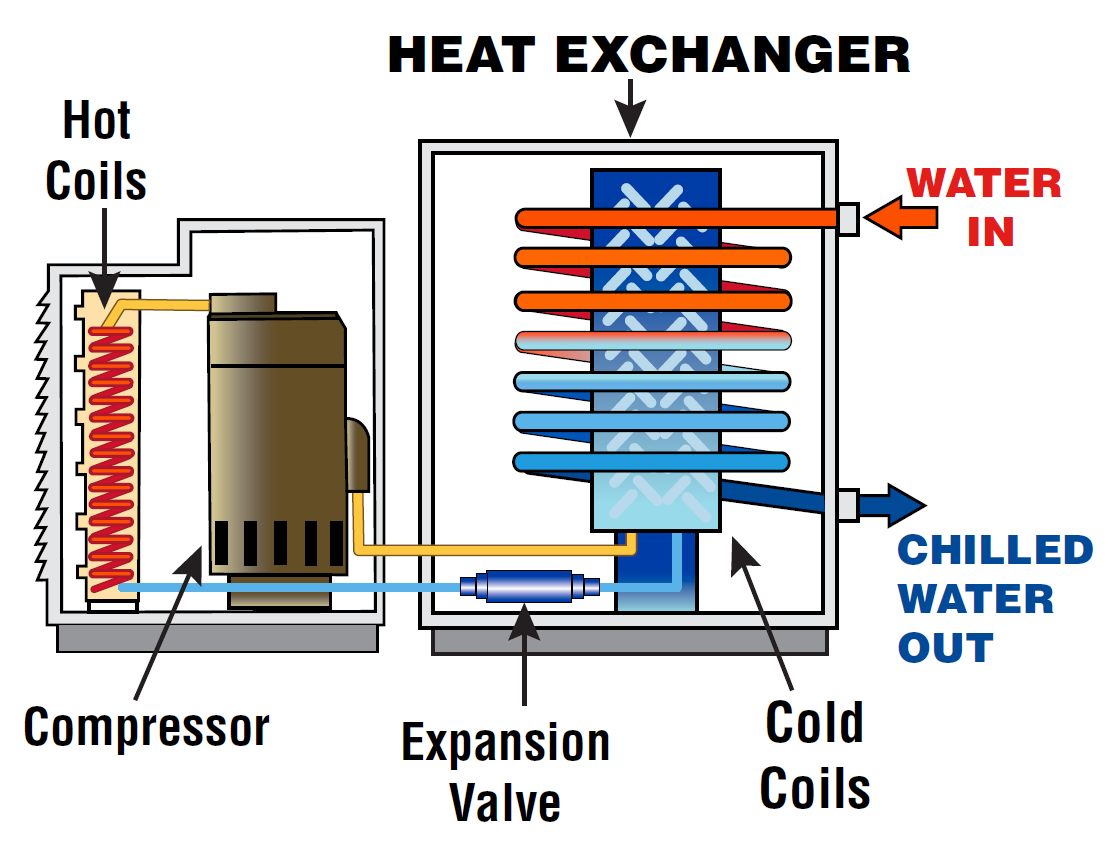

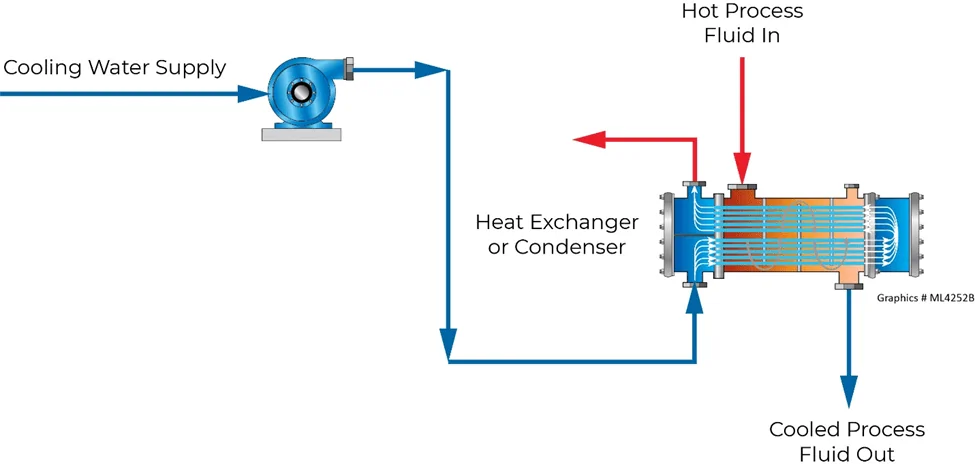

Cooling towers don’t create cold; they reject heat. They use evaporation to move heat from water into the air, pushing the water temperature closer and closer to the surrounding atmosphere’s limit. That limit is the wet bulb temperature, and the distance between your cooled water and that limit is called the approach temperature.

Think of wet bulb temperature as the finish line, and approach temperature as how close you manage to get.

Wet bulb temperature (WBT) is the lowest temperature water can theoretically reach through evaporative cooling under specific ambient conditions. It depends on:

Air temperature

Humidity

Air movement

The higher the humidity, the higher the wet bulb temperature—and the harder it becomes for a cooling tower to perform.

Dry bulb temperature is what your weather app shows. Wet bulb temperature is what your cooling tower “feels.”

On a hot, dry day, the gap between dry bulb and wet bulb is large, and cooling towers work efficiently. On hot, humid days, that gap shrinks—and performance drops. This is why cooling towers are always rated against wet bulb temperature, not dry bulb.

Approach temperature is the difference between the cold water outlet temperature of the cooling tower and the ambient wet bulb temperature.

The formula is simple:

Approach = Cold Water Temperature – Wet Bulb Temperature

If the wet bulb is 27°C and the cold water temperature is 32°C, the approach is 5°C.

Simple math—big consequences.

Most cooling towers are designed with approach temperatures between:

3°C (very low approach, high performance)

4–5°C (common, balanced design)

6–7°C (economical, compact design)

Lower approach means better cooling—but at a higher cost.

No matter how large or advanced your cooling tower is, it cannot cool water below the wet bulb temperature. This is a physical law, not a design flaw.

Asking a cooling tower to beat wet bulb temperature is like asking a sponge to hold more water than it physically can. Design can improve efficiency—but it cannot break physics.

The closer the approach temperature is to the wet bulb temperature, the more difficult heat rejection becomes. Each degree closer requires:

More airflow

More fill surface area

Larger fans

Higher energy input

This is why approach temperature and wet bulb temperature are inseparable in cooling tower design.

Let’s look at a simple example:

Wet bulb temperature: 28°C

Design approach: 5°C

Cold water temperature: 33°C

If you reduce the approach to 3°C, the cold water target drops to 31°C—but the cooling tower may need to be significantly larger to achieve it.

Approaching wet bulb temperature is like chasing a train that’s already moving. The closer you get, the harder it becomes to close the gap. That final 1–2°C near wet bulb often costs more than the first 5°C combined.

Approach temperature controls how “hard” the cooling tower must work.

A lower approach reduces chiller condensing temperature, which:

Improves chiller efficiency

Reduces compressor power

Lowers operating cost

However, these gains must be balanced against higher fan power and capital cost.

Low-approach cooling towers require:

Larger fill volume

Taller or wider structures

Stronger airflow systems

That means more space, more material, and higher initial investment.

There’s no universal “best” approach—only the right approach for your application.

Better chiller performance

Stable process temperatures

Lower long-term energy cost

Larger footprint

Higher upfront cost

More sensitive to fouling and water quality

Low approach is powerful—but only when justified.

HVAC systems often tolerate higher approach temperatures, because comfort cooling is flexible. Industrial processes—especially plastics, chemicals, and pharmaceuticals—often demand low approach to maintain product quality and production stability.

A plant requires 31°C cooling water.

Local wet bulb: 28°C

Required approach: 3°C

This is a high-performance requirement and demands a carefully engineered cooling tower—not an off-the-shelf design.

One of the biggest myths is that “lower approach is always better.” In reality, over-design wastes money, while under-design causes operational pain. The best systems are balanced, not extreme.

Experienced manufacturers optimize:

Fill geometry

Airflow patterns

Fan efficiency

Structural layout

The goal is not just to meet the approach on paper—but to achieve it reliably in real-world conditions.

MACH Cooling (https://www.machcooling.com/) designs cooling towers based on actual site wet bulb data, operating conditions, and lifecycle cost analysis. Instead of pushing unnecessarily low approaches, MACH Cooling engineers systems that deliver the required performance with the best balance of efficiency, size, and long-term value.

Ask the right questions:

What is the local design wet bulb temperature?

How sensitive is the process or chiller system?

What is the energy cost versus capital budget?

Approach temperature is not a default—it’s a strategy.

Can approach temperature change over time?

Yes. Fouling, airflow restriction, and poor water treatment can increase approach.

Is a 3°C approach always achievable?

Technically yes—but economically and practically, not always advisable.

The relationship between approach temperature and wet bulb temperature defines both the physical limit and economic reality of cooling tower performance. Understanding this relationship allows you to design smarter systems, avoid over- or under-sizing, and achieve reliable, efficient cooling.

With experienced manufacturers like MACH Cooling, approach temperature becomes more than a number—it becomes a competitive advantage built into your cooling system from day one.