We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-01-21 Origin: Site

When your facility reaches a point where cooling demand is steady, critical, and non-negotiable, choosing the right cooling tower becomes more than a technical decision—it becomes a business decision. A 115 ton cooling tower for chiller and process cooling sits right in that “sweet spot”: powerful enough for demanding applications, yet compact and efficient enough to keep capital and operating costs under control.

Whether you’re supporting water-cooled chillers in an HVAC system or removing continuous heat from industrial processes, this guide walks you through everything you need to know—clearly, practically, and without unnecessary jargon.

A cooling tower’s job is simple in theory: reject heat to the atmosphere. In practice, it’s the backbone of your entire cooling system. A 115 ton cooling tower is designed to reject approximately 1.38 million BTU per hour of heat, making it ideal for medium-capacity chiller plants and stable industrial loads.

Think of it like a reliable engine running at optimal RPM—not oversized, not overstressed, just right.

In cooling technology, a “ton” doesn’t refer to weight. It refers to cooling capacity, where one ton equals 12,000 BTU/hr. So when we say 115 ton cooling tower, we’re talking about its heat rejection capability—not its physical size.

This capacity is commonly matched with:

100–120 TR water-cooled chillers

Medium industrial process loops

Combined HVAC and process cooling systems

Chiller cooling and process cooling may look similar on paper, but they behave very differently in the real world.

Chiller cooling is predictable. Loads rise and fall with ambient temperature and occupancy.

Process cooling is relentless. Production lines don’t take breaks, and heat loads are often constant.

A 115 ton cooling tower for chiller and process cooling is engineered to handle both scenarios—stable performance for chillers and durability for round-the-clock industrial operation.

Why not go smaller? Why not oversize “just in case”? Because efficiency lives in balance.

Choosing a 115 ton unit means:

Better chiller efficiency and lower condensing temperature

Reduced fan energy consumption

Less water waste

Lower long-term maintenance costs

It’s like buying shoes that actually fit—you walk farther, longer, and more comfortably.

Commercial buildings, hospitals, hotels, data centers, and office complexes rely on 115 ton cooling towers to keep indoor environments comfortable and energy bills predictable.

Plastic injection molding, chemical processing, food & beverage production, and pharmaceutical plants all depend on consistent heat rejection to protect equipment and product quality.

From compressors and heat exchangers to auxiliary power systems, this cooling capacity supports mission-critical operations without overengineering.

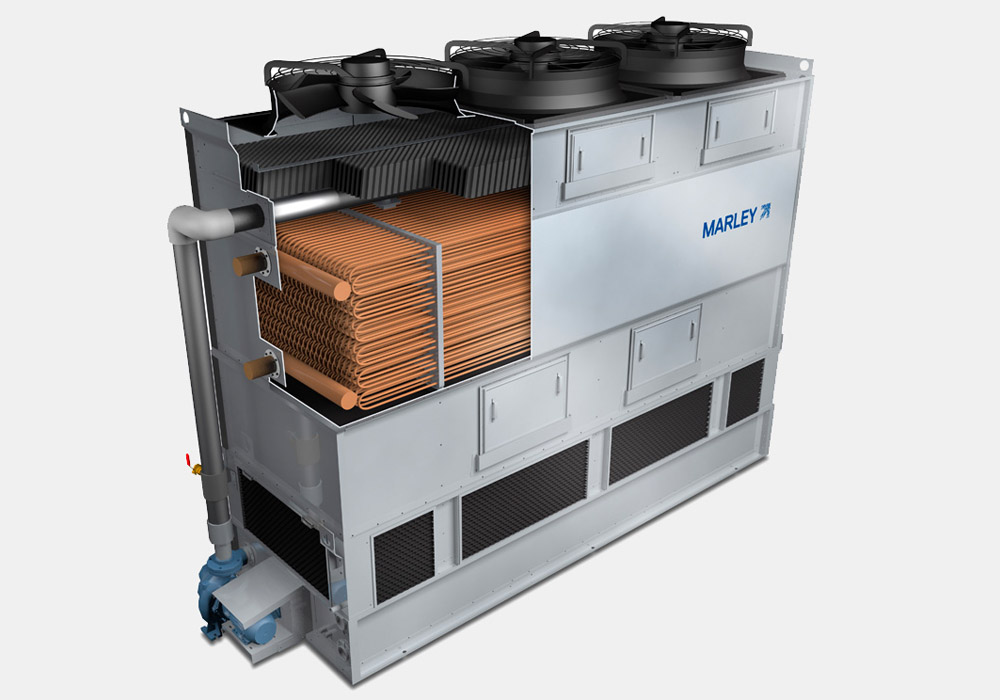

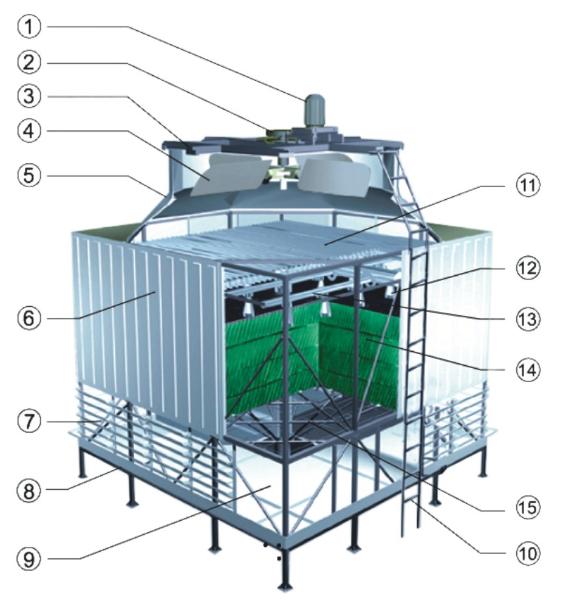

A cooling tower is more than a fan and a basin—it’s a carefully coordinated system.

Most modern designs use FRP (Fiber Reinforced Plastic) for corrosion resistance, lightweight strength, and long service life—even in harsh industrial environments.

PVC fill maximizes air-water contact, allowing heat to escape efficiently—like increasing the surface area of a radiator.

Energy-efficient axial fans paired with high-quality motors ensure strong airflow with minimal power consumption and low noise levels.

Uniform water spray and advanced drift eliminators reduce water loss, protect nearby equipment, and meet environmental standards.

Open circuit cooling towers are widely used for chiller systems and general industrial cooling due to lower initial cost.

Closed circuit cooling towers (fluid coolers) keep process fluid isolated, ideal for sensitive or contaminated processes.

The right choice depends on your application—and the right manufacturer will help you decide.

FRP cooling towers offer superior corrosion resistance and minimal maintenance.

Galvanized steel towers provide strength and lower upfront cost.

For long-term ROI and harsh conditions, FRP often wins the race.

A well-designed 115 ton cooling tower reduces chiller lift, lowers fan power, and minimizes makeup water usage. Advanced airflow design and drift control mean you cool smarter—not harder.

Proper installation is half the battle:

Adequate airflow clearance

Level concrete foundation

Correct piping and basin layout

Manufacturers like MACH Cooling provide detailed drawings and technical support to ensure smooth commissioning.

Routine inspection of:

Water quality

Fill condition

Fan alignment

Basin cleanliness

…keeps your cooling tower operating efficiently for decades, not just years.

Scale, biological growth, and airflow restriction are common—but preventable. Good design, proper water treatment, and regular maintenance eliminate most headaches before they start.

Key factors include:

Ambient wet-bulb temperature

Required approach temperature

Water quality

Noise limits

Available space

This is where experience matters.

MACH Cooling (https://www.machcooling.com/) is a professional cooling tower manufacturer specializing in customized solutions for chiller and process cooling. With advanced engineering, strict quality control, and global project experience, MACH Cooling delivers 115 ton cooling towers designed for efficiency, durability, and long-term value.

From design to delivery, their focus is simple: cooling systems that work—day after day.

Initial price is only part of the equation. Energy savings, reduced downtime, lower maintenance, and longer lifespan make a high-quality 115 ton cooling tower a smart long-term investment.

Can one 115 ton cooling tower support multiple chillers?

Yes, with proper hydraulic and control design.

Is customization available?

Absolutely—materials, fans, motors, and controls can be tailored to your project.

Is it suitable for export projects?

Yes. MACH Cooling supplies customized units for global markets.

A 115 ton cooling tower for chiller and process cooling is a balanced, efficient, and reliable solution for modern HVAC and industrial systems. When engineered and manufactured by an experienced supplier like MACH Cooling, it becomes more than equipment—it becomes long-term operational security.

If your project demands stable performance without unnecessary complexity, this cooling tower capacity might be exactly what you’re looking for.