We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-01-13 Origin: Site

Central air conditioning systems are the backbone of modern buildings. From office towers and shopping malls to hospitals and airports, they quietly maintain comfortable indoor environments day and night. But behind this comfort lies an important challenge—heat rejection.

Every central AC system removes heat from indoor spaces, and that heat must go somewhere. Without an effective way to discharge it, the entire system would quickly lose efficiency or even shut down. This is exactly why cooling towers play such a critical role.

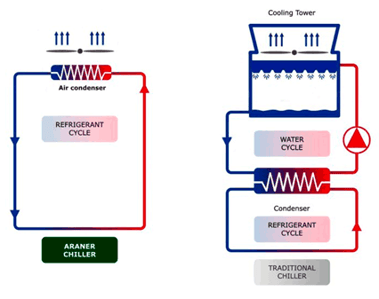

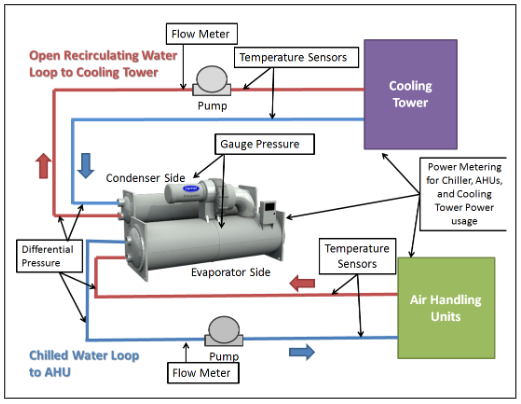

A cooling tower is a heat rejection device designed to remove excess heat from water-cooled systems. In central air conditioning applications, cooling towers work together with water-cooled chillers to release heat absorbed from indoor spaces into the atmosphere.

In simple terms, if the chiller is the “engine” of the cooling system, the cooling tower is its “radiator.”

Cooling towers rely on the natural process of evaporative cooling. Hot condenser water flows from the chiller to the cooling tower, where it is distributed over fill media. As air passes through the tower, a small portion of the water evaporates, carrying heat away.

The cooled water then returns to the chiller to absorb more heat, completing a continuous cycle.

Think about how sweating cools the human body. When sweat evaporates, it removes heat. Cooling towers operate on the same principle—just on a much larger, industrial scale.

Central air conditioning systems handle enormous heat loads, especially in large commercial and industrial buildings. Cooling towers ensure this heat is safely and efficiently discharged, preventing thermal overload.

Without proper heat rejection, condenser pressure rises, forcing compressors to work harder. Cooling towers help stabilize operating conditions, protecting expensive HVAC equipment and improving reliability.

Water-cooled systems supported by cooling towers are significantly more efficient than air-cooled alternatives, particularly in hot climates or high-load applications.

Although cooling towers require a higher initial investment, their lower energy consumption and longer system lifespan often result in reduced total lifecycle costs.

One of the biggest advantages of cooling towers is their contribution to energy efficiency. By maintaining lower condenser temperatures, chillers operate more efficiently and consume less electricity.

When condenser water is cooler, compressors require less power to do the same amount of work.

Over time, energy savings from cooling towers can significantly outweigh installation and maintenance costs, making them a smart long-term investment.

Water transfers heat far more effectively than air. That’s why large buildings, district cooling plants, and industrial facilities rely on water-cooled chillers paired with cooling towers.

Office buildings, shopping centers, hotels, and convention halls use cooling towers to deliver consistent and cost-effective cooling.

Factories and processing plants often require cooling towers for both HVAC and process cooling.

These facilities demand absolute temperature stability. Cooling towers provide the reliability and redundancy needed to avoid costly downtime.

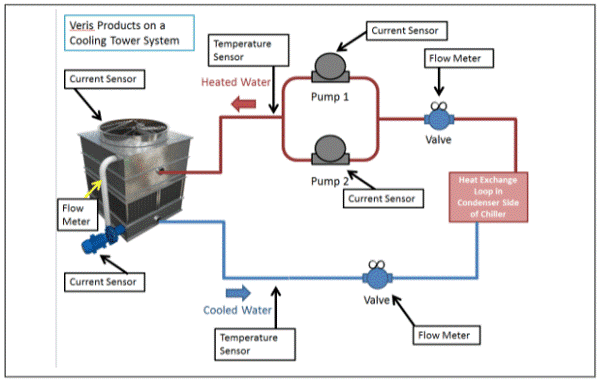

A typical cooling tower system includes:

Tower structure and casing

Heat transfer fill media

Fans and drive systems

Drift eliminators

Water distribution and basin

Each component plays a vital role in overall performance and efficiency.

Without cooling towers, central air conditioning systems face:

Excessive energy consumption

Frequent equipment failures

Shortened chiller lifespan

Increased maintenance costs

In short, the system becomes inefficient and unreliable.

Cooling tower selection depends on heat load, ambient wet-bulb temperature, and system configuration.

An experienced manufacturer ensures proper sizing, material selection, and long-term system performance.

Professional manufacturers offer:

Customized engineering solutions

High-efficiency designs

Quality-controlled manufacturing

Reliable after-sales support

These factors directly affect system reliability and operating costs.

Mach Cooling (https://www.machcooling.com/) is a professional cooling tower manufacturer specializing in high-efficiency solutions for central air conditioning systems. With advanced engineering capabilities and strict quality standards, Mach Cooling delivers durable, energy-saving cooling towers tailored to real-world operating conditions.

Cooling towers are not optional components—they are essential to the performance, efficiency, and longevity of central air conditioning systems. By effectively rejecting heat, reducing energy consumption, and protecting critical equipment, cooling towers make modern large-scale cooling possible.

Choosing the right cooling tower and a trusted manufacturer like Mach Cooling ensures stable operation, lower costs, and long-term peace of mind.

What Is The Difference Between Field Erected And Modular Cooling Towers?

How To Define A Cooling Tower Based on Heat Transfer Principles

Noise Reduction And Maintenance Advantages in Cooling Towers

How Smart Monitoring Enhances Cooling Tower Water Efficiency

Cooling Tower Treatment Companies for Food And Beverage Industry