We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-12-11 Origin: Site

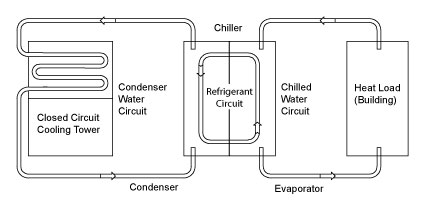

A cooling tower is a key component in large-scale HVAC systems. In many office buildings, hospitals, hotels, data centers, or large commercial facilities, the HVAC system uses chilled water or condenser water loops. A cooling tower — or more generally a water cooling tower system — removes the excess heat from that water and rejects it into the atmosphere, allowing the cooled water to recirculate and maintain comfortable indoor environments.

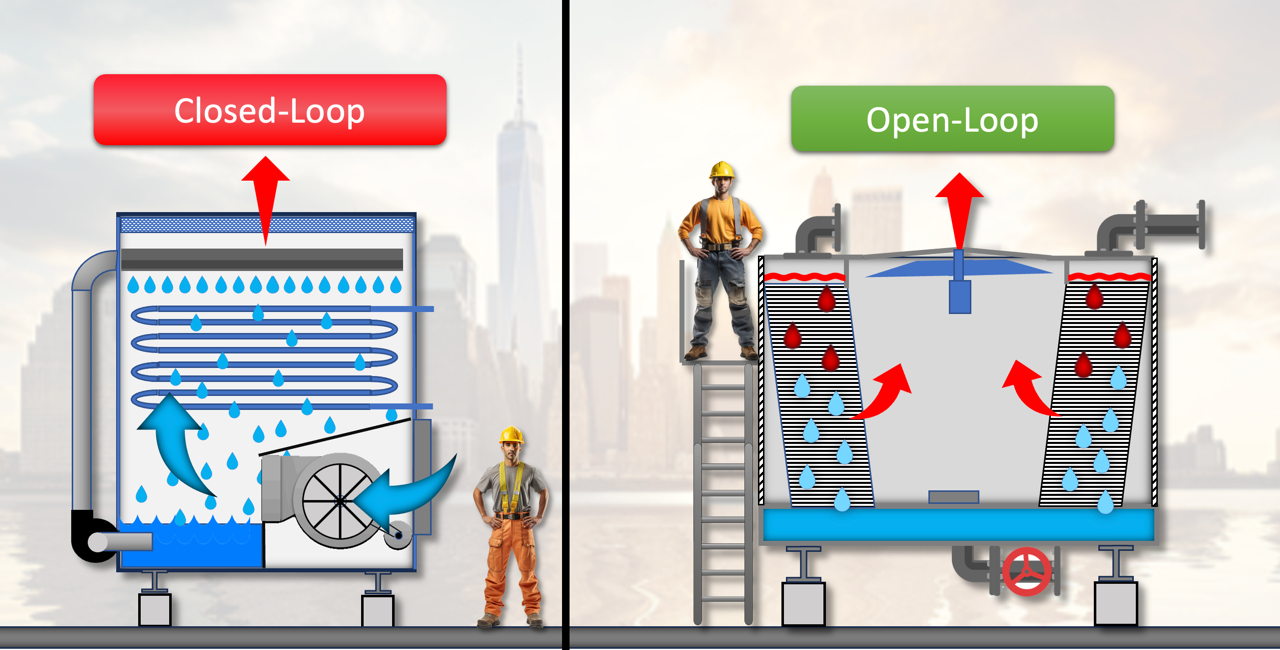

Whether configured as an open (water cooled) tower or a closed loop cooling tower, the cooling tower ensures efficient heat removal and stable operation of HVAC chillers or condensers.

In the context of HVAC (heating, ventilation, and air conditioning), a cooling tower is essentially a heat rejection device. Its role is to take warm water — typically condenser water returning from a chiller or heat-pump condenser — and cool it down so it can be reused.

The warm water enters the tower, is cooled (usually via evaporation + air flow), then is returned to the chiller or condenser loop.

This process is repeated continuously: water circulates in a loop, rejecting building heat via the tower and bringing cooled water back to the HVAC system.

For buildings with high cooling loads — high-rise offices, hospitals, hotels, large residential complexes, data centers — a cooling tower is often essential.

Water has much higher thermal capacity compared to air, enabling efficient transport of heat from the building to the cooling tower.

By using evaporation and airflow, cooling towers achieve lower water temperatures than air-cooled alternatives, which improves chiller efficiency.

A water cooling tower system can scale to handle large loads — much more effective than rooftop air-cooled condensers for big buildings.

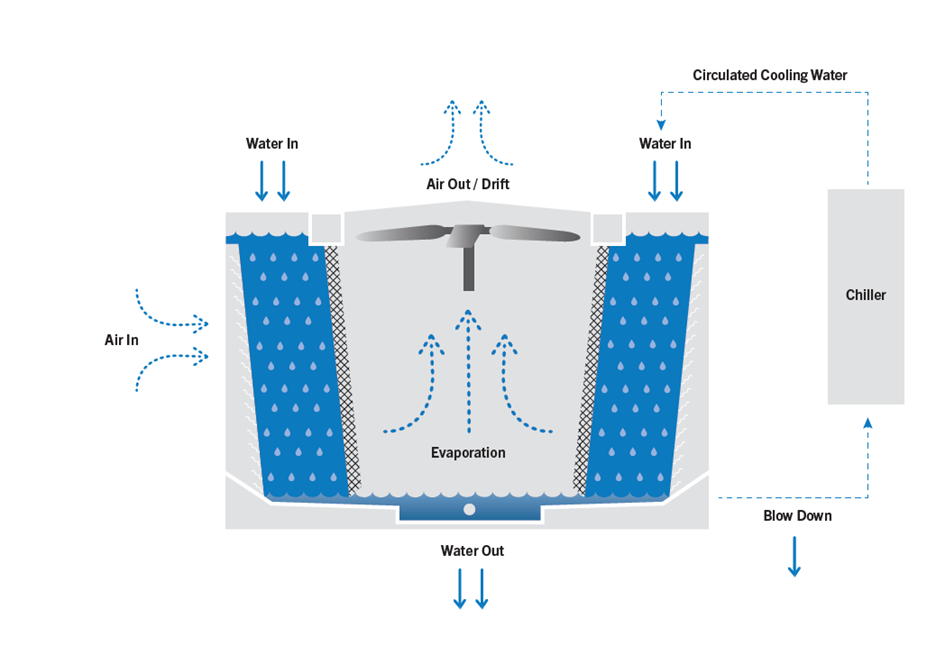

At its core, a cooling tower converts warm water into cooler water by rejecting heat into the air — mostly via evaporative cooling. (

Warm water (condenser water) returns from a chiller or heat pump condenser and is pumped into the cooling tower, usually near the top.

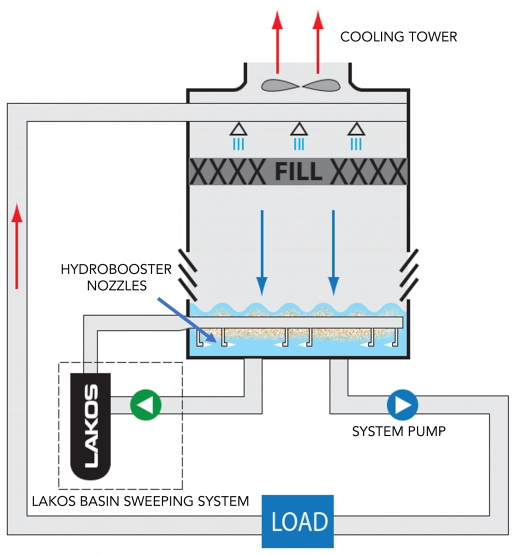

Inside the tower, water is sprayed or distributed over a “fill” — a structured media or packing designed to spread water into thin films or droplets. This increases surface area for contact with air.

Air is drawn or forced through the tower (depending on fan type), passing over the falling water. The airflow can be upward (counterflow) or horizontal (crossflow), depending on design.

As air and water meet, a small portion of the water evaporates. The evaporation removes latent heat, cooling the remaining water. This is the main mechanism for heat rejection.

The cooled water collects in a cold-water basin at the bottom, then is pumped back to the chiller or condenser to absorb more heat.

The warm, moist air (carrying the evaporated water) is exhausted to the atmosphere — usually via the top outlet of the tower.

Flow Summary Table

| Step | Description |

|---|---|

| 1 | Warm condenser/chiller water enters the tower |

| 2 | Water distributed over fill media or spray nozzles |

| 3 | Air drawn or forced through the tower for contact |

| 4 | Partial evaporation removes heat, cooling water |

| 5 | Cooled water collected and returned to HVAC loop |

| 6 | Warm, moist air expelled to atmosphere |

HVAC systems may use different types of cooling towers depending on requirements: either open (water cooled) towers or closed loop cooling towers (also called closed-circuit towers).

Water from the condenser flows directly into the tower, contacts air and partially evaporates.

The same water is reused (minus evaporation and drift losses) and recirculated.

It is simple, cost-effective, and widely used in building HVAC systems.

For certain applications — where fluid purity, contamination control, or corrosion prevention is important — a closed loop cooling tower may be preferred. In such a tower:

The process or condenser fluid circulates inside a sealed coil (tube bundle) inside the tower.

A secondary external water circuit sprays water over the outside of the coils, and air is drawn over them, allowing evaporative cooling across the coil wall. The process fluid inside the coils remains isolated from air and external contaminants.

Cooled process fluid returns to the HVAC system, while the spray-water loop circulates, with only the spray water being exposed to evaporation.

Keeps condenser or process water clean and isolated — reduces risk of scale, corrosion, or microbial growth.

Reduced maintenance on the main loop, since water does not contact air or pick up contaminants.

Suitable for sensitive HVAC applications (high-rise buildings, hospitals, data centers) where water quality and system reliability matter.

Manufacturers like MACH Cooling offer this kind of water cooling tower system — combining closed-circuit coils with spray-water loops to meet HVAC needs.

Here are the main components found in a typical HVAC cooling tower (whether open or closed-loop), and some important terminology:

| Component / Term | Role / Meaning |

|---|---|

| Fill (packing) | Material (plastic, wood, etc.) that slows water flow and provides large air–water contact area for evaporation / heat exchange. |

| Water distribution / spray nozzles | Distribute warm water evenly over fill (open tower) or over closed coils (closed loop). |

| Fans / air-flow system | Induce or force airflow through the tower — critical for evaporative cooling and heat rejection. |

| Cold-water collection basin (sump) | Collects cooled water at the bottom before recirculation. |

| Drift eliminators | Reduce water droplet loss carried out with air, improving water efficiency and reducing drift. |

| Closed-circuit coil (for closed loop towers) | Seals process fluid from air, enabling indirect cooling — ideal for sensitive HVAC systems. |

| Make-up water & Blowdown | In open towers, makeup water replaces evaporated/drift losses; blowdown removes concentrated solids to control water quality. |

Important Terms

Range: Difference between the entering water temperature and the leaving (cooled) water temperature.

Approach: Difference between the cooled water temperature and ambient air wet-bulb temperature — indicates cooling tower performance potential.

Evaporative cooling: The principal mechanism by which heat is rejected; evaporation removes latent heat from water.

As a manufacturer, MACH Cooling offers a variety of water cooling tower systems tailored to HVAC needs — including closed loop cooling towers and water cooled towers designed for building-scale condenser or chilled-water systems.

Their closed-circuit cooling tower design isolates the process fluid (condenser or chilled water) from contact with external air. That ensures the water loop remains clean, preventing contamination or scaling — beneficial for long-term HVAC operation in buildings sensitive to water quality.

By offering a robust water cooling tower system, MACH Cooling enables efficient, reliable rejection of building heat — especially important for large buildings with high cooling loads (office towers, hospitals, hotels, data centers, etc.).

Their systems allow building owners / HVAC engineers to choose between open-loop towers (for maximum simplicity and cost-effectiveness) or closed-loop towers (for cleanliness, maintenance reduction, and longevity), depending on project requirements.

While cooling towers provide powerful advantages for HVAC, they also require proper design and maintenance:

In open towers, water is exposed to air, which can introduce contaminants, minerals, biological growth, scaling, or corrosion over time. Regular water treatment and periodic blowdown are needed to manage mineral concentration.

In closed-loop towers, the process fluid loop remains sealed — reducing contamination risk. However, the spray-water loop still needs maintenance, water treatment, and occasional blowdown or makeup water.

Cooling efficiency depends on ambient air conditions: wet-bulb temperature, humidity, airflow, and tower design — high humidity or poor airflow reduces effectiveness.

Drift and evaporative losses consume water over time — water management (makeup water, blowdown, drift eliminators) is important.

Mechanical components (fans, pumps, distribution nozzles) require routine inspection and maintenance for reliable performance.

In HVAC systems — especially for large buildings or facilities — a water cooling tower is a critical component of the water cooling tower system, enabling efficient rejection of heat from chillers or condensers to the atmosphere. By circulating water, exposing it to air, and using evaporative cooling, a cooling tower transforms warm condenser water into cooled water ready to absorb more heat — making indoor climate control possible at scale.

Depending on design and requirements, the tower may be a simple open (water cooled) tower, or a more advanced closed loop cooling tower, where the process fluid remains sealed from air for cleanliness and reliability. Manufacturers like MACH Cooling supply these systems, giving HVAC engineers flexibility to choose the configuration best suited to their building.

Case Studies: Effective Makeup Water Management in Cooling Towers

What Is The Difference Between Field Erected And Modular Cooling Towers?

How To Define A Cooling Tower Based on Heat Transfer Principles

Noise Reduction And Maintenance Advantages in Cooling Towers

How Smart Monitoring Enhances Cooling Tower Water Efficiency

Cooling Tower Treatment Companies for Food And Beverage Industry