We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-12-25 Origin: Site

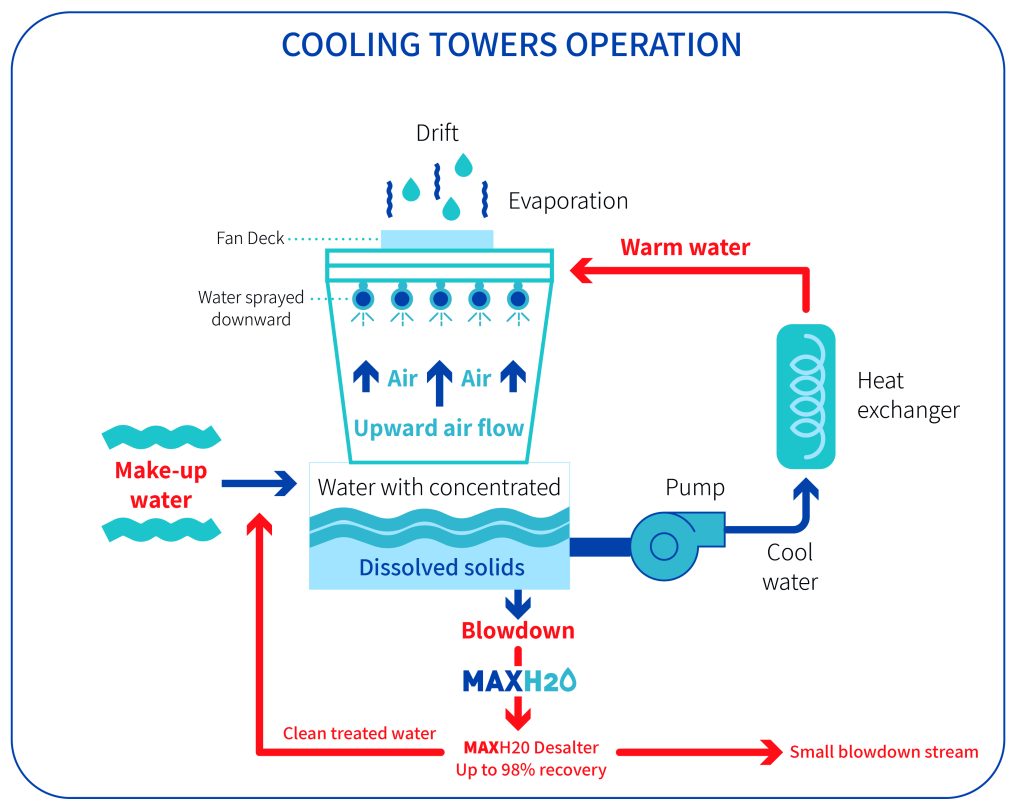

Cooling towers are the backbone of many industrial processes and HVAC systems, quietly handling massive heat loads every day. But have you ever wondered why some water is intentionally discharged from a cooling tower? That process is called blowdown—a critical step that keeps your cooling tower healthy, efficient, and reliable. Ignoring blowdown is like skipping an oil change for your car—it may run for a while, but eventually, damage builds up.

Cooling towers transfer heat from water to the atmosphere, allowing chilled water to return to the system. During this process, water evaporates, leaving behind minerals, salts, and other impurities. Over time, these dissolved solids concentrate in the remaining water, which can cause scaling, corrosion, and microbial growth if left unchecked. Blowdown is the controlled removal of part of this water to maintain water quality and safe operation.

Cooling tower blowdown is the controlled discharge of water from a cooling tower system to prevent the accumulation of dissolved minerals and other contaminants. As water evaporates, dissolved solids increase, and blowdown helps maintain them at safe levels.

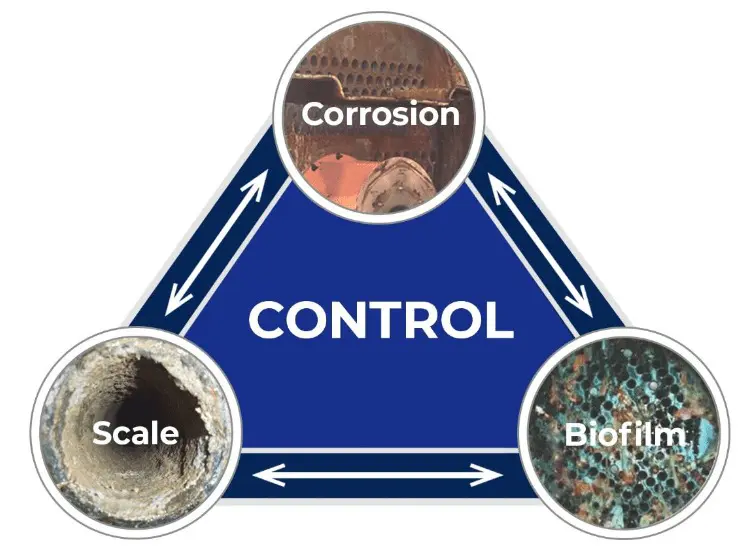

Without blowdown, water chemistry becomes unbalanced. High concentrations of minerals can lead to:

Scaling on heat exchanger surfaces and tower fill

Corrosion of metal components

Bacterial and algae growth

Regular blowdown prevents these issues, ensuring consistent operation and prolonging the life of pumps, piping, and cooling tower components.

Water contains naturally occurring minerals such as calcium, magnesium, and silica. Evaporation concentrates these minerals, which can form hard deposits on tower fills, heat exchangers, and piping. Scaling reduces heat transfer efficiency and increases energy costs.

As dissolved solids accumulate, water conductivity increases, accelerating corrosion of metal components. Blowdown helps maintain safe conductivity levels, protecting pumps, piping, and structural elements.

Concentrated water can promote bacteria, algae, and biofilm formation. Blowdown removes part of the water, limiting nutrients for microbial growth and keeping the system sanitary.

Continuous blowdown removes a small portion of water constantly through a calibrated valve. This keeps water chemistry stable and precise.

Intermittent or batch blowdown removes water periodically, based on water quality measurements or fixed schedules. It is common in smaller systems or older towers.

Modern towers often use conductivity or TDS sensors to automatically adjust blowdown rates, ensuring optimal water quality without manual intervention.

In some installations, operators manually open blowdown valves at regular intervals, relying on water testing to determine timing and volume.

Valves regulate the discharge of water. They may be manual, motor-operated, or solenoid-controlled, depending on system complexity.

Conductivity meters, TDS meters, and flow meters monitor water chemistry and ensure proper blowdown rates are maintained.

Blowdown water is safely routed to sewers, treatment plants, or recycling systems. Proper piping ensures smooth flow and prevents backflow or leaks.

![]()

Water is removed from the surface of the basin. This method is simpler but may not effectively remove heavier debris.

Water is discharged from the bottom of the basin, removing sediment along with dissolved solids. It is more effective for systems with sediment accumulation.

The blowdown rate depends on:

Cycles of concentration

Water hardness

Evaporation rate

Correct calculations ensure water is conserved while preventing scaling and corrosion.

The chemistry of makeup water affects blowdown frequency. Hard water requires more frequent blowdown, while soft water allows longer intervals.

Excessive blowdown wastes energy and water. Optimizing blowdown improves system efficiency and reduces operational costs.

Blowdown water contains high concentrations of minerals and treatment chemicals. If discharged untreated, it can harm the environment. Many facilities use treatment, neutralization, or recycling to minimize environmental impact.

Blowdown water can often be reused for:

Boiler feedwater

Irrigation

Industrial processes

This reduces freshwater consumption and operational costs.

Using scale inhibitors, corrosion inhibitors, and biocides can extend the time between blowdowns and reduce water consumption.

Blowdown affects water, chemical, and energy costs. Properly designed and optimized blowdown systems reduce waste and improve overall system efficiency, providing significant long-term savings.

How often should blowdown be performed?

It depends on water hardness, cycles of concentration, and tower size. Continuous systems adjust automatically, while intermittent systems require monitoring.

Is blowdown necessary for all cooling towers?

Yes. Any evaporative cooling system requires blowdown to prevent scaling, corrosion, and microbial growth.

Can blowdown water be reused?

Yes, with proper treatment, blowdown water can be recycled for boilers, irrigation, or industrial applications.

Cooling tower blowdown may seem like “wasting water,” but in reality, it is a smart, essential process. It protects equipment, maintains efficiency, prevents scaling and corrosion, and controls biological growth.

By understanding and managing blowdown effectively, operators can balance water conservation, energy efficiency, and environmental responsibility. Proper blowdown isn’t just maintenance—it’s a long-term investment in reliability and performance.

What Is The Difference Between Field Erected And Modular Cooling Towers?

How To Define A Cooling Tower Based on Heat Transfer Principles

Noise Reduction And Maintenance Advantages in Cooling Towers

How Smart Monitoring Enhances Cooling Tower Water Efficiency

Cooling Tower Treatment Companies for Food And Beverage Industry