We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-12-25 Origin: Site

Cooling towers are the backbone of many industrial and HVAC systems, quietly handling massive heat loads day after day. But here’s a question most people don’t ask until something goes wrong: what protects a cooling tower from debris entering with the water?

That’s exactly where a traveling cooling tower screen comes in.

Unlike static screens or simple trash racks, traveling screens work continuously. They don’t wait for operators to clean them. They move, clean themselves, and keep debris from disrupting cooling tower performance. In large or open-water cooling systems, they’re not a luxury—they’re a necessity.

Whenever cooling towers draw water from rivers, lakes, seawater, or open basins, debris is unavoidable. Leaves, algae, plastic waste, weeds, and even small aquatic organisms can quickly enter the intake system.

If this debris reaches pumps or spray headers, the result is predictable: clogging, reduced heat transfer, higher energy use, and unplanned shutdowns. A traveling cooling tower screen acts like a 24/7 security guard, stopping trouble before it enters the system.

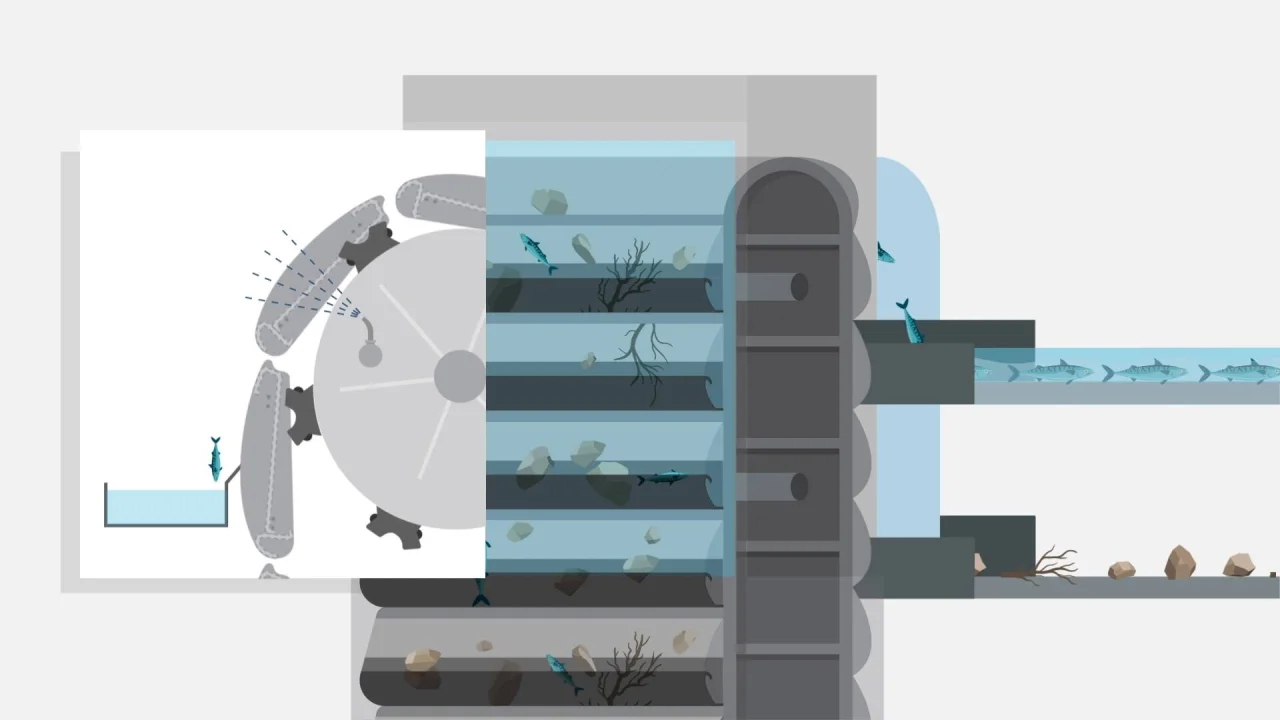

A traveling cooling tower screen is a mechanical screening device installed at the cooling tower water intake. It continuously removes debris from incoming water while allowing a steady flow into the cooling tower basin.

The word traveling refers to movement. Instead of remaining fixed, the screen rotates on chains or tracks. As it moves, it carries captured debris upward to a cleaning zone, where spray water removes the debris automatically.

Open water sources are unpredictable. Seasonal changes, storms, plant growth, and human activity all increase debris loads. What looks like clean water today can become debris-heavy tomorrow.

Debris doesn’t just block flow—it slowly chokes system efficiency. Pumps work harder, spray nozzles clog, and heat exchangers foul. Over time, this leads to rising energy costs and shortened equipment life.

As water flows toward the cooling tower, it passes through the traveling screen. Debris is trapped on the upstream face of the screen panels while clean water continues downstream.

On the intake side, the screen acts as a barrier, stopping debris without significantly restricting water flow.

As the screen rotates, trapped debris is lifted out of the water and enters a spray wash zone. High-pressure water jets clean the screen and flush debris into a collection trough or discharge channel.

Screen panels determine what size debris is removed. The mesh or bar spacing is selected based on system sensitivity and debris type.

The drive system—motors, chains, sprockets, and shafts—keeps the screen moving smoothly, even under heavy debris conditions.

This system is critical. Without effective spray cleaning, debris would accumulate and reduce screen efficiency.

These are the most common type. Water flows directly through the screen panels, making them ideal for standard cooling tower intakes.

Dual-flow screens handle water from both sides, allowing higher flow rates and wider intake structures.

Designed to meet environmental regulations, these screens reduce harm to aquatic life while maintaining effective debris removal.

Stainless steel offers excellent strength and corrosion resistance, making it ideal for industrial and seawater cooling towers.

These materials are lightweight, corrosion-proof, and increasingly popular for modern cooling tower applications.

A trash rack is a fixed, coarse barrier that blocks large debris. A traveling screen goes further by continuously removing debris automatically. In many systems, trash racks serve as the first defense, while traveling screens provide refined, ongoing protection.

Continuous debris removal

Reduced manual cleaning

Improved cooling efficiency

Lower pump and maintenance costs

Increased system reliability

Think of it as upgrading from manual cleaning to an automatic system that never takes a break.

Traveling cooling tower screens are widely used in:

Power plants

Petrochemical facilities

Steel and metal processing plants

District cooling systems

Desalination and water treatment facilities

Periodic inspection of chains, bearings, and screen panels ensures long-term reliability.

Clogged spray nozzles reduce cleaning efficiency, so routine flushing and inspection are essential.

Key selection factors include:

Cooling tower flow rate

Debris size and concentration

Screen opening size

Intake structure geometry

Environmental and regulatory requirements

Selecting the right traveling screen means aligning engineering design with real operating conditions.

Although traveling screens cost more upfront than static screens, they significantly reduce downtime, labor costs, and energy losses over time. In most cases, the payback period is short due to improved operational stability.

Are traveling screens required for all cooling towers?

They are strongly recommended for cooling towers using open or debris-prone water sources.

Can traveling screens replace trash racks?

No. They work best together, providing layered protection.

A traveling cooling tower screen is far more than a mechanical accessory—it is a critical safeguard for modern cooling tower systems. By continuously removing debris, it protects equipment, stabilizes performance, and reduces operating costs.

In large-scale or open-water cooling systems, reliability starts at the intake. And when reliability matters, traveling cooling tower screens keep everything moving smoothly.

Case Studies: Effective Makeup Water Management in Cooling Towers

What Is The Difference Between Field Erected And Modular Cooling Towers?

How To Define A Cooling Tower Based on Heat Transfer Principles

Noise Reduction And Maintenance Advantages in Cooling Towers

How Smart Monitoring Enhances Cooling Tower Water Efficiency

Cooling Tower Treatment Companies for Food And Beverage Industry