We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-12-20 Origin: Site

Natural draft cooling towers are large, often iconic structures used in industrial and power plant settings to remove waste heat by harnessing the natural movement of air. Unlike mechanical draft towers that rely on fans, natural draft towers use buoyancy—the natural rise of warm air—to pull in ambient air and cool the circulating water.

This article explains what natural draft cooling towers are, how they work, their advantages and limitations, key design features, and how manufacturers like Mach Cooling (https://www.machcooling.com/) supply and support these systems in industrial cooling applications.

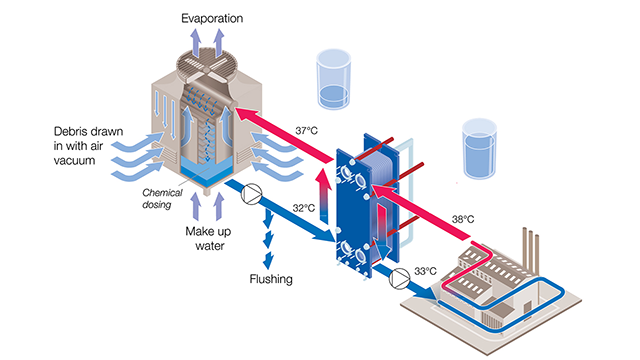

Cooling towers are heat rejection devices that transfer thermal energy from circulating water to the atmosphere. In many industries—power generation, petrochemical processing, HVAC, and manufacturing—effective cooling is essential to operational reliability and efficiency.

Natural draft cooling towers are distinct due to their reliance on natural convection, large structure, and minimal moving parts.

Natural draft cooling towers operate on a simple physical principle: hot air rises. As warm water from the industrial process enters the tower, it flows over fill media that increases surface area and promotes heat transfer. The heat warms the air, which becomes less dense and rises through the tower’s large chimney-like structure. As this warm air exits at the top, cooler ambient air is drawn in at the bottom.

Unlike mechanical draft towers, which use fans to force or induce airflow, natural draft towers depend solely on:

Buoyancy of heated air

Tower geometry (height and shape)

Ambient air conditions (temperature, humidity)

Understanding the main parts of a natural draft tower helps explain why they are so effective in large installations.

The structural shell of the tower is typically hyperboloid in shape—wider at the base and narrow at the mid-section—with advantages in strength and airflow.

Shell Features:

| Component | Purpose |

|---|---|

| Hyperbolic Structure | Maximizes airflow with minimal material |

| Concrete or FRP Construction | Resists corrosion and environmental wear |

| Large Internal Volume | Supports effective natural convection |

Mach Cooling supplies towers with optimized structural shells suitable for different industrial environments.

Fill media is the internal packing where hot water spreads into thin films to maximize contact with cooling air. In natural draft towers, fill quality directly impacts heat transfer effectiveness.

Common fill types:

Splash fill – water broken into droplets

Film fill – thin water films on large surface area

Water distribution nozzles ensure even water spread onto the fill media. Proper distribution is crucial for consistent cooling.

To illustrate differences, here’s a comparison:

| Feature | Natural Draft | Mechanical Draft |

|---|---|---|

| Air Movement | Natural convection | Fans (induced/forced) |

| Energy Use | Very low | Higher (fan motors) |

| Size | Very large | Variable sizes |

| Application | High-capacity industrial | Industrial + commercial |

| Noise Level | Low | Moderate to high |

| Installation Cost | High | Moderate |

| Maintenance | Lower (no fans) | Higher (fan systems) |

As shown, natural draft towers are ideal for high-capacity, low-operating-energy systems, especially in power and heavy industry.

Without fans or motors, natural draft towers have minimal electricity requirements, leading to significant operating cost savings over time.

Structures built by reputable manufacturers like Mach Cooling use durable materials and quality engineering to withstand decades of service with routine maintenance.

Natural airflow produces far less noise than mechanical draft systems—an advantage in settings with noise restrictions.

When dealing with very large heat loads (tens of thousands of tons), natural draft towers are often more efficient at moving massive volumes of air without mechanical assistance.

While advantageous for specific scenarios, natural draft cooling towers also have limitations.

These towers require significant space due to their size and base diameter, making them less suitable for tighter urban installations.

Construction and civil work for natural draft towers are more expensive upfront than smaller mechanical systems.

Wind, ambient temperature, and humidity influence performance, requiring careful engineering and site analysis by experts such as those at Mach Cooling to ensure optimal results.

Natural draft towers are most common in:

Power plants (coal, gas, nuclear)

Large chemical and petrochemical complexes

Steel mills and heavy manufacturing

Municipal water treatment plants

Their ability to handle massive heat loads with energy-efficient operation makes them indispensable in heavy industry.

The hyperbolic shape is more than aesthetic. It:

Promotes smooth airflow patterns

Enhances buoyancy effects

Reduces structural stress

Materials must resist corrosion from constant water exposure and weather. Common choices include:

| Material | Benefits | Typical Use |

|---|---|---|

| Concrete | Long life, strong | Large power plant towers |

| FRP (Fiberglass) | Corrosion-resistant | Medium-sized towers |

| Coated Steel | Cost-effective | Smaller installations |

Mach Cooling provides corrosion-resistant options tailored to climatic and industrial conditions.

Routine maintenance ensures long service life and optimal performance.

Inspect structural shell for cracks

Check water distribution lines

Clean fill media as needed

Monitor drift eliminators for buildup

Operators should track:

Outlet water temperature

Airflow characteristics

Water usage and blowdown rates

Regular monitoring helps predict when refurbishment or part replacement is needed.

Below is an example illustrating how a natural draft tower supports cooling in a hypothetical power plant:

| Parameter | Value |

|---|---|

| Heat Load | 50,000 tons |

| Tower Height | 150 meters |

| Annual Operating Energy | ~0 (no fans) |

| Water Flow | 200,000 m³/day |

| Maintenance Frequency | Quarterly checks |

In cases like this, energy savings from natural convection far outweigh higher initial investment, especially over long operating periods.

Mach Cooling (https://www.machcooling.com/) is a trusted cooling tower manufacturer offering:

Custom natural draft cooling towers

Design, engineering, fabrication, and installation

Long-lasting structures suited to local conditions

Technical support and lifecycle services

With experience in industrial cooling systems worldwide, Mach Cooling helps clients select the right tower type, size, and materials to match process needs and environmental conditions.

Natural draft cooling towers are powerful, energy-efficient solutions for large-scale cooling needs. By leveraging natural convection, they reduce operating energy costs and require minimal mechanical components. However, their application requires careful design, robust materials, and experienced engineering—attributes that set brands like Mach Cooling apart.

Whether for a power plant, processing facility, or heavy industrial site, understanding how natural draft towers work is key to making informed decisions about cooling infrastructure.

What Is The Difference Between Field Erected And Modular Cooling Towers?

How To Define A Cooling Tower Based on Heat Transfer Principles

Noise Reduction And Maintenance Advantages in Cooling Towers

How Smart Monitoring Enhances Cooling Tower Water Efficiency

Cooling Tower Treatment Companies for Food And Beverage Industry