We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-02-09 Origin: Site

In a cooling tower system, water is everything. It absorbs heat, transfers energy, and keeps the entire operation running smoothly. But here’s the catch: too little water can damage equipment, and too much water wastes money. That’s exactly why a cooling tower water level sensor exists.

Think of a water level sensor as the nervous system of a cooling tower. It constantly senses what’s happening inside the basin and reacts instantly. Small device, big responsibility—and a huge impact on efficiency, safety, and operating costs.

A cooling tower water level sensor is designed to monitor, control, and stabilize the water level in the cooling tower basin. It ensures the system always operates within a safe and optimal range, regardless of evaporation losses, blowdown, or load changes.

In modern cooling systems, relying on manual inspection or basic mechanical control is no longer enough. Automated water level sensing is now a standard requirement for reliable operation.

Water level control directly affects system performance, equipment lifespan, and operating costs.

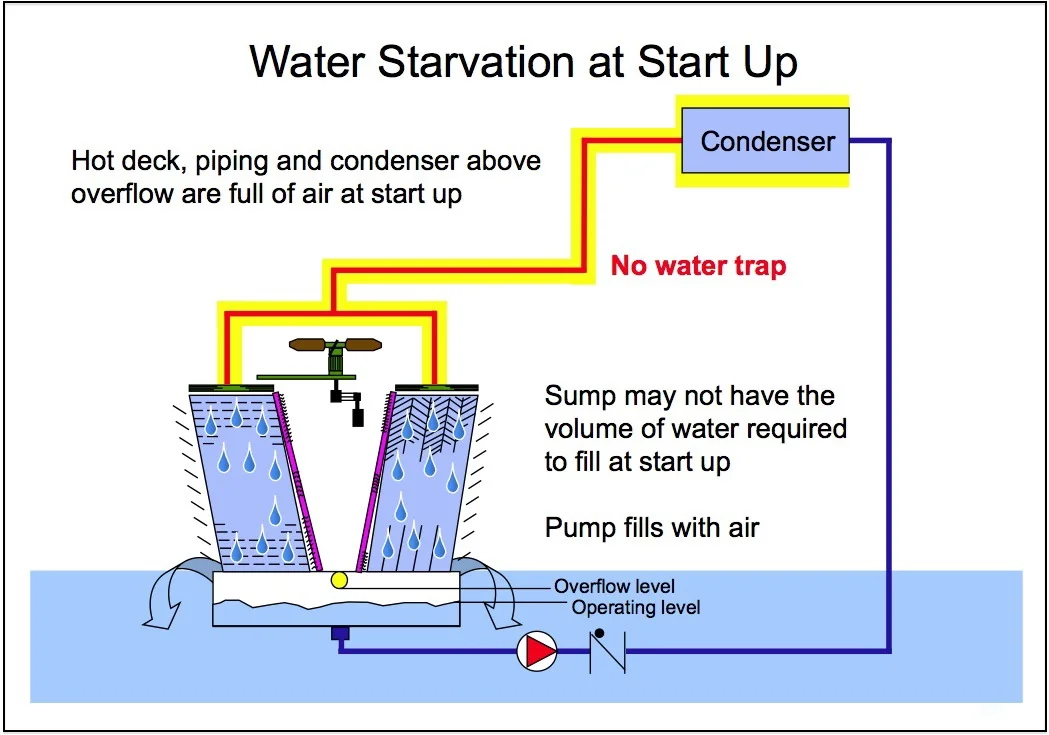

When the water level drops too low, circulation pumps may run dry. This can cause cavitation, overheating, seal failure, and even complete pump burnout. It’s similar to running a car engine without oil—damage happens fast and repairs are expensive.

Low water levels can also reduce cooling efficiency, leading to higher process temperatures and unstable system operation.

High water levels may seem harmless, but they create their own problems. Overflow leads to wasted makeup water, increased sewer or discharge fees, and unstable basin conditions. Over time, this silent water loss adds up to significant operating costs.

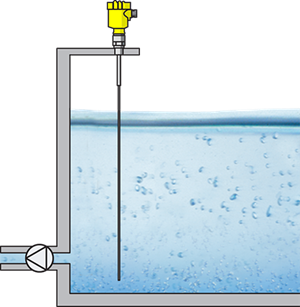

A cooling tower water level sensor is a device installed in or above the cold-water basin to detect the current water level and send signals to a control system or makeup water valve. Based on these signals, the system automatically adds or stops adding water.

In short, it removes guesswork and replaces it with precision.

Water level sensors work by detecting physical changes caused by the presence or absence of water. Depending on the sensor type, this may involve:

Mechanical movement

Electrical conductivity

Water pressure

Distance measurement

Once the water reaches a preset level, the sensor sends a signal to open or close the makeup water valve, keeping the system balanced.

Different cooling tower designs and operating conditions require different sensor technologies.

Float sensors are one of the most traditional options. As the water level rises or falls, a floating component moves and mechanically opens or closes a valve. They are simple, reliable, and cost-effective, but their accuracy is limited compared to electronic options.

Electronic sensors provide higher precision and are ideal for automated systems.

Conductivity sensors detect water by measuring electrical conductivity. When water touches the probe, it completes a circuit, triggering a control signal. These sensors are widely used in industrial cooling towers.

Pressure sensors measure hydrostatic pressure at the bottom of the basin. Since pressure increases with water depth, the sensor can calculate the exact water level with high accuracy.

Ultrasonic sensors use sound waves to measure the distance between the sensor and the water surface. Because they do not touch the water, they are well-suited for harsh, dirty, or chemically aggressive environments.

The operation process is straightforward and highly reliable:

The sensor continuously monitors basin water level

Evaporation or blowdown causes the level to drop

The sensor detects the low-level setpoint

A signal is sent to open the makeup water valve

Fresh water enters the basin

The sensor detects the high-level setpoint

The valve closes automatically

This closed-loop control ensures stable operation without human intervention.

Water level sensors are the foundation of automatic makeup water control systems. They ensure that only the required amount of water is added, preventing both shortages and overflow.

This precision directly supports water conservation, energy efficiency, and consistent cooling performance.

By maintaining a stable operating range, cooling tower water level sensors protect systems from their two most common failures: overflow and dry running. Preventing these issues reduces downtime, avoids costly repairs, and extends equipment life.

Installing a cooling tower water level sensor delivers long-term advantages:

Reduced water waste

Lower operating and maintenance costs

Improved pump and system reliability

Better control of makeup water

Increased automation and safety

In most cases, the sensor pays for itself quickly through water and maintenance savings.

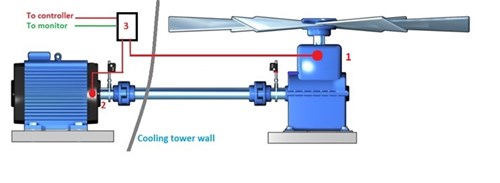

Modern cooling tower water level sensors integrate seamlessly with PLC, SCADA, and BMS systems. This allows operators to monitor water levels remotely, receive alarms, analyze trends, and optimize system performance in real time.

Proper installation is essential for accurate readings. Sensors should be mounted away from turbulent areas, direct spray zones, and debris accumulation points. Correct positioning ensures reliable performance and long service life.

Routine inspection and cleaning help prevent false readings. Common issues include scale buildup, fouling, wiring problems, or calibration drift. Regular maintenance keeps sensors accurate and dependable.

Experienced cooling tower manufacturers design systems that fully support advanced water level sensing and control. Companies like MACH Cooling integrate water level sensor compatibility into their cooling tower designs, enabling efficient makeup water control, automation integration, and long-term operational stability.

Learn more at: https://www.machcooling.com/

When selecting a water level sensor, consider:

Cooling tower size and application

Water quality and contamination levels

Required accuracy and response time

Integration with existing control systems

Environmental conditions

The right choice ensures reliability, efficiency, and ease of operation.

A cooling tower water level sensor may seem like a small component, but its impact is enormous. By maintaining stable water levels, it protects equipment, reduces water waste, lowers operating costs, and supports automation.

In modern cooling systems, a reliable water level sensor is not optional—it’s essential.

Sustainable Cooling Towers: Balancing Evaporation And Water Use

Lightweight And Corrosion-Resistant Composites in Cooling Towers

Understanding Cooling Tower Collapse: Causes And Consequences

Filtration And Treatment Technologies for Blowdown Water Recycling

How To Choose The Right Closed Circuit Cooling Tower Manufacturer

Biggest Cooling Tower in The World: Engineering Scale, Design, And Global Impact

30 Ton Cooling Tower Explained: Capacity, Design, And Applications

Why Pultruded FRP Cooling Towers Outperform Traditional FRP Towers