We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-02-11 Origin: Site

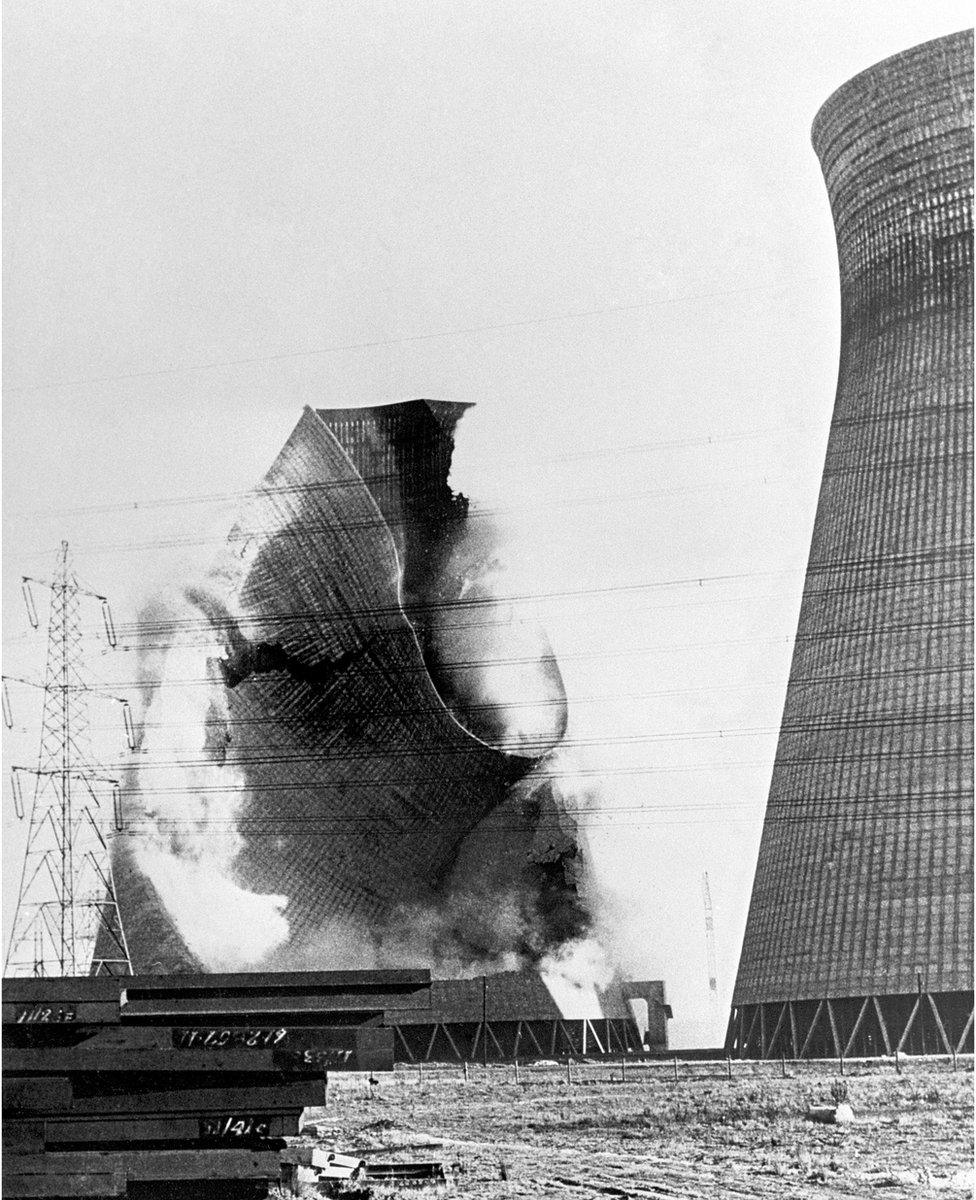

Cooling towers are massive structures, often towering over industrial facilities and power plants. They’re designed to handle heavy thermal loads with reliability — but what happens when they fail? A cooling tower collapse is not just a headline; it’s a serious structural, operational, and safety event with far-reaching consequences. In this article, we’ll break down what causes collapses, real historical examples, and how to prevent these disasters in the future.

Cooling towers play a vital role in industrial and power applications by removing waste heat and maintaining system efficiency. When one collapses, the fallout goes beyond structural loss — it threatens human lives, operational continuity, and the environment. Understanding how and why collapses occur helps facility managers, engineers, and decision-makers protect assets and people.

At its simplest, a cooling tower rejects heat from water systems into the atmosphere. Water flows through internal fill while air moves across it, carrying away heat. Towers can be massive — hundreds of feet tall — and are vital parts of many industrial processes.

There are several types, from natural draft hyperbolic towers to mechanical draft towers with fans. Each has unique design considerations, but all share one vulnerability: if their structure fails, the consequences can be catastrophic.

A collapse isn’t just one thing. It can be:

Structural collapse: The tower’s physical form fails — walls, shell, or support give way.

Mechanical failure: Internal components fail, which can sometimes lead to progressive issues and structural damage.

Both can lead to total failure if ignored.

Sudden collapse happens without much warning — like a sudden failure of a support element.

Progressive collapse starts small and worsens over time until the structure can no longer bear loads.

Learning from history helps us build safer towers today.

One of the deadliest cooling tower collapses occurred in West Virginia, USA. A reinforced concrete cooling tower under construction failed because the concrete had not gained enough strength to support the load, causing the entire structure and scaffolding to collapse, resulting in 51 deaths.

Three of eight cooling towers at the Ferrybridge station in the UK collapsed due to wind-induced vibration and design shortcomings that underestimated wind loads. Engineers later strengthened the remaining towers based on improved structural insights.

In Australia, a cooling tower collapsed due to rotted wooden structural supports that deteriorated from chlorine corrosion. Limited maintenance and unaddressed degradation played a significant role, highlighting how long-term neglect can lead to failure.

If construction progresses before materials have adequate strength, sudden structural failure can occur.

Temporary supports and scaffolding must be engineered and inspected rigorously — if they fail, the entire structure can follow.

Cooling tower components are constantly exposed to water and oxygen, creating an environment where rust and corrosion can weaken critical elements over time.

Towers are tall and slender, making them vulnerable to high winds. Extreme weather events like typhoons can overload towers beyond design limits, leading to sudden collapse.

Fan imbalance, motor failure, and continuous vibration can accelerate wear and fatigue in the structure. When vibration gets out of control, it can contribute to progressive collapse.

Long-term biological fouling and microbial growth can weaken supports and internal structures. A buildup of biofilm and microbial corrosion can accelerate decay of wood and metal components.

The absolute worst outcome is loss of human life. Past collapses have resulted in significant fatalities due to structural failure during construction or operation.

A collapsed cooling tower means unplanned downtime, costly rebuilds, lost production, and potentially expensive legal liabilities. Production halts can ripple through supply chains.

Debris, contamination from coolant fluids, and disrupted operations can all lead to environmental hazards requiring costly remediation.

Routine inspections to catch corrosion, structural wear, and mechanical issues can stop failure before it starts. Regular checks can reveal weak points long before catastrophic collapse.

Designing with stronger materials like FRP panels, corrosion-resistant alloys, and reinforced concrete helps towers withstand environmental and operational stresses. Partnering with expert manufacturers during the design phase makes a big difference.

Modern towers can integrate sensors to track vibrations, stress, and structural health in real time. These early warning systems help engineers take action before failure.

Manufacturers like Mach Cooling (https://www.machcooling.com/) specialize in designing towers with an eye toward long-term stability, corrosion resistance, and overall safety. Their engineers understand how to balance thermal performance with structural integrity.

Choosing a manufacturer that offers ongoing maintenance support, training, and performance monitoring ensures safety throughout the cooling tower’s lifespan.

Cooling tower collapse is rare, but when it happens, the consequences are dire. Most collapses result from a mix of weak design, neglected maintenance, environmental stress, and construction errors. The best defense is good design, regular inspection, and proactive maintenance — starting with trusted manufacturers who understand both performance and safety.

Why do cooling towers collapse during construction?

Often due to inadequate material strength or improper sequencing of loads.

Can old cooling towers suddenly collapse?

Yes — long-term corrosion, vibration fatigue, and environmental stress can weaken structures over time.

Are natural disasters a leading cause of collapse?

Wind loads and typhoons can trigger collapses if towers aren’t engineered for extreme conditions.

Is microbial growth really a structural risk?

Yes, microbial corrosion and biofouling can weaken internal supports and accelerate deterioration.

How can I prevent collapse in my facility’s cooling tower?

Routine inspections, corrosion mitigation, structural upgrades, and working with experienced manufacturers like Mach Cooling are key.

Sustainable Cooling Towers: Balancing Evaporation And Water Use

Lightweight And Corrosion-Resistant Composites in Cooling Towers

Understanding Cooling Tower Collapse: Causes And Consequences

Filtration And Treatment Technologies for Blowdown Water Recycling

How To Choose The Right Closed Circuit Cooling Tower Manufacturer

Biggest Cooling Tower in The World: Engineering Scale, Design, And Global Impact

30 Ton Cooling Tower Explained: Capacity, Design, And Applications

Why Pultruded FRP Cooling Towers Outperform Traditional FRP Towers