We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-02-10 Origin: Site

When it comes to medium-sized cooling requirements, the 30 ton cooling tower is one of the most practical and widely used solutions on the market. It sits perfectly between small residential systems and large industrial installations, offering a balance of capacity, efficiency, and cost that makes sense for many projects.

But what does “30 ton” really mean? How is a 30 ton cooling tower designed? And where does it perform best in real-world applications?

Let’s break it all down—clearly, practically, and in plain English.

Cooling towers are the unsung heroes of HVAC and industrial cooling systems. They quietly remove heat day after day, often operating in harsh outdoor conditions with minimal downtime.

The 30 ton cooling tower has become especially popular because it fits the needs of a wide range of commercial and light industrial facilities. It’s powerful enough to handle meaningful heat loads, yet compact enough to install on rooftops or limited ground space.

Think of it as the “just right” option—big enough to perform, small enough to stay efficient.

The popularity of 30 ton cooling towers isn’t accidental. They’re commonly chosen because they offer:

Flexible installation options

Reasonable initial investment

Manageable operating costs

Compatibility with many standard chiller systems

From office buildings to hotels and small factories, this capacity range checks a lot of boxes.

This is one of the most common questions, and it’s worth clarifying.

In cooling terminology, a “ton” does not refer to weight. One cooling ton equals 12,000 BTU per hour of heat removal. A 30 ton cooling tower is designed to reject approximately 360,000 BTU/hr of heat under standard operating conditions.

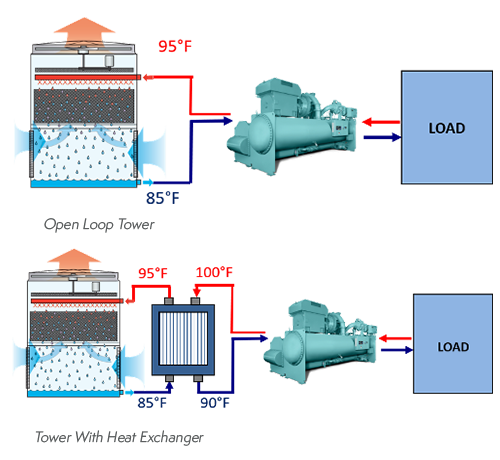

In practice, a cooling tower often needs to reject more heat than the nominal chiller capacity it supports. That’s because it handles not only the building’s heat load, but also the heat generated by pumps, compressors, and inefficiencies in the system.

At its core, a cooling tower relies on one simple principle: evaporative cooling.

Warm water from the system enters the tower and is distributed over fill media. Air is drawn through the tower by a fan. As a small portion of the water evaporates, it removes heat from the remaining water.

Only about 1–2% of the circulating water evaporates, but that small loss carries away a significant amount of heat—similar to how sweat cools your skin on a hot day.

Every 30 ton cooling tower is made up of several essential components, each playing a specific role.

Most modern towers use FRP (Fiber Reinforced Plastic) casings. FRP offers excellent corrosion resistance, low weight, and long service life, especially in humid or coastal environments.

The fill increases the surface area and contact time between air and water. Efficient fill design directly impacts cooling performance.

The fan moves air through the tower. Energy-efficient motors and properly designed fan blades help reduce power consumption and noise.

Uniform water distribution ensures consistent cooling and prevents hot spots or scaling inside the tower.

Not all 30 ton cooling towers are built the same way. Design choices affect performance, footprint, and maintenance.

Open circuit cooling towers allow water to come into direct contact with air. They are the most common and cost-effective option.

Closed circuit cooling towers keep the process fluid isolated in coils, reducing contamination and scaling.

Crossflow designs are quieter and easier to maintain, while counterflow towers are more compact and often more thermally efficient.

Induced draft cooling towers dominate the market because they offer better airflow control, higher efficiency, and reduced recirculation of hot air.

FRP cooling towers are the most common choice today. They resist corrosion, require minimal maintenance, and perform well in aggressive environments.

Steel towers may offer a lower initial cost, but they often require protective coatings and more frequent maintenance, especially in humid or corrosive conditions.

Selecting the right capacity is critical for performance and efficiency.

A 30 ton cooling tower is often paired with chillers serving medium-sized commercial buildings, depending on climate, occupancy, and internal heat loads.

For light industrial processes, a 30 ton unit is often sufficient to handle machine cooling or process heat without oversizing the system.

Efficiency matters—not just for operating costs, but also for sustainability.

Most 30 ton cooling towers use fan motors ranging from 0.75 to 2.2 kW, depending on design and airflow requirements.

Water consumption includes evaporation, drift, and blowdown. Well-designed towers minimize water loss while maintaining water quality.

These towers can be installed on rooftops or on ground-level concrete foundations, making them suitable for a wide range of sites.

Proper piping layout, electrical grounding, and vibration isolation are essential for safe and reliable operation.

Regular maintenance typically includes:

Monitoring water quality

Inspecting fans and motors

Cleaning fill and strainers

A well-designed FRP 30 ton cooling tower can operate reliably for 20 years or more with proper maintenance.

Office buildings and shopping centers rely on 30 ton cooling towers for stable HVAC performance.

Quiet operation and reliability make them ideal for occupant-sensitive environments.

Manufacturing plants use 30 ton cooling towers for equipment and process cooling where larger systems would be unnecessary.

Choosing the right manufacturer is just as important as choosing the right capacity.

Mach Cooling designs and manufactures high-quality cooling towers with a strong focus on engineering, durability, and efficiency. Their 30 ton cooling tower solutions feature robust FRP structures, optimized thermal performance, and customization options for different climates and applications.

Learn more at https://www.machcooling.com/

While initial cost is an important factor, long-term value depends on operating efficiency, maintenance requirements, and service life. A well-built 30 ton cooling tower often delivers better returns over time than a cheaper, lower-quality alternative.

Is a 30 ton cooling tower enough for my system?

In many medium-sized HVAC and light industrial applications, yes—but proper load calculation is essential.

Can a 30 ton cooling tower be customized?

Absolutely. Materials, fan types, and configurations can be tailored to project needs.

A 30 ton cooling tower offers an ideal balance of capacity, efficiency, and flexibility. It’s powerful enough for demanding applications, yet compact and economical enough for everyday commercial use.

With the right design, proper installation, and a reliable manufacturer like Mach Cooling, a 30 ton cooling tower can deliver dependable performance for decades—quietly doing its job, day after day.

Sustainable Cooling Towers: Balancing Evaporation And Water Use

Lightweight And Corrosion-Resistant Composites in Cooling Towers

Understanding Cooling Tower Collapse: Causes And Consequences

Filtration And Treatment Technologies for Blowdown Water Recycling

How To Choose The Right Closed Circuit Cooling Tower Manufacturer

Biggest Cooling Tower in The World: Engineering Scale, Design, And Global Impact

30 Ton Cooling Tower Explained: Capacity, Design, And Applications

Why Pultruded FRP Cooling Towers Outperform Traditional FRP Towers