We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-02-10 Origin: Site

In today’s industrial cooling world, not all FRP cooling towers are created equal. While traditional FRP cooling towers have long been valued for corrosion resistance and lightweight construction, a new generation of pultruded FRP cooling towers is rapidly setting a higher benchmark for strength, durability, and long-term performance.

So what makes pultruded FRP cooling towers stand out? Why are more engineers, plant owners, and EPC contractors choosing them over conventional FRP designs?

Let’s break it down—clearly, practically, and from a real-world engineering perspective.

Cooling towers operate in some of the harshest environments imaginable: constant moisture, chemical exposure, vibration, wind loads, and thermal cycling. Materials matter. That’s why Fiber Reinforced Plastic (FRP) has become a preferred alternative to steel and concrete.

But within FRP itself, there’s a major distinction—how the FRP is made.

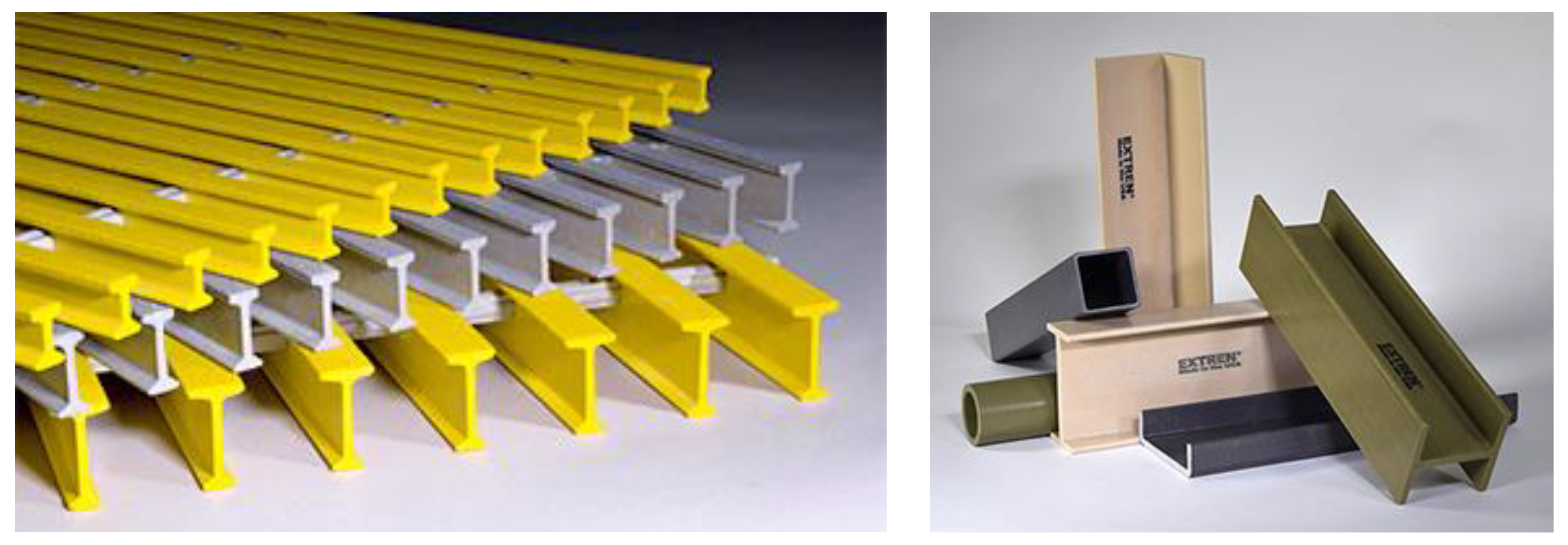

Traditional FRP cooling towers rely on molded or hand lay-up components. Pultruded FRP cooling towers, on the other hand, use precision-engineered structural profiles manufactured through a controlled, automated process. The difference in performance is significant.

An FRP cooling tower uses composite materials made from fiberglass and resin to form its structure, casing, and internal components. Compared with steel or concrete towers, FRP cooling towers offer:

Excellent corrosion resistance

Reduced structural weight

Lower maintenance requirements

Longer service life in aggressive environments

However, these benefits depend heavily on the quality and consistency of the FRP structure itself.

Early FRP cooling towers were typically constructed using molded panels or hand-laid fiberglass. While effective in basic applications, these methods introduce variability in thickness, fiber orientation, and strength.

Pultruded FRP represents the next step in this evolution—bringing industrial-level consistency, strength, and predictability to cooling tower structures.

A pultruded FRP cooling tower uses load-bearing structural members produced by the pultrusion process. These include columns, beams, bracing, and support frames that form the backbone of the tower.

Unlike molded FRP panels, pultruded profiles are engineered specifically for structural performance, making them ideal for large and heavy-duty cooling tower systems.

Pultrusion is a continuous manufacturing process where fiberglass reinforcements are pulled through a resin bath and then shaped and cured in a heated die. The result is a profile with:

Continuous fiber alignment

Uniform resin distribution

Precise dimensions

High strength-to-weight ratio

Think of it as the difference between hand-poured concrete and factory-cast structural beams—one is variable, the other engineered for reliability.

Traditional FRP components often have randomly oriented fibers and inconsistent thickness. Pultruded FRP profiles, by contrast, align fibers along load paths, delivering superior tensile and flexural strength.

This structural consistency is one of the key reasons pultruded FRP cooling towers outperform traditional FRP designs in demanding industrial environments.

Traditional FRP cooling towers still offer several advantages, including corrosion resistance and lower upfront cost. However, they also face limitations such as:

Reduced load-bearing capacity

Structural creep over time

Deformation under wind and vibration

Greater dependence on field reinforcement

In small or low-stress applications, these limitations may be acceptable. In large-scale or mission-critical installations, they become risks.

Pultruded FRP cooling towers are designed as true structural systems—not just enclosures.

Pultruded FRP columns and beams can support larger fans, higher airflow rates, and heavier mechanical loads without deformation. This allows for taller towers and higher thermal performance.

In regions exposed to typhoons, hurricanes, or seismic activity, structural rigidity matters. Pultruded FRP frames maintain alignment and stability, reducing the risk of vibration-related failures.

One of the biggest advantages of FRP is corrosion resistance—but consistency is just as important.

Pultruded FRP components feature controlled resin content and uniform fiber distribution. This ensures that every structural member resists corrosion in the same way, even in:

Coastal environments

Chemical plants

Power stations

High-humidity industrial zones

Traditional FRP cooling towers often require reinforcement or partial structural replacement after 10–15 years. Pultruded FRP cooling towers are engineered for 20–30 years or more of reliable service.

Their resistance to fatigue, UV exposure, and mechanical stress makes them ideal for continuous-operation facilities.

Pultruded FRP cooling towers are typically delivered as modular systems with pre-engineered structural members.

This approach offers clear benefits:

Faster on-site assembly

Reduced labor costs

Shorter plant downtime

Improved installation accuracy

Because pultruded FRP does not rust, warp, or delaminate like traditional materials, maintenance demands are significantly lower. There is no need for repainting, anti-corrosion treatment, or structural patching.

For plant operators, this means fewer shutdowns and lower operating costs.

While pultruded FRP cooling towers may carry a slightly higher initial cost, their long-term economics are compelling. Reduced maintenance, extended service life, and improved operational stability result in a lower total cost of ownership.

In long-term projects, lifecycle cost matters far more than upfront savings.

Structural rigidity directly impacts performance. Pultruded FRP frames keep fans, gearboxes, and drive systems properly aligned, minimizing vibration and energy losses.

The result is smoother operation, higher efficiency, and improved reliability over time.

Pultruded FRP cooling towers are especially well suited for:

Chemical and petrochemical plants

Power generation facilities

Refineries

Coastal and offshore installations

High-demand industrial cooling systems

Leading cooling tower manufacturers increasingly design their systems around pultruded FRP structures to meet modern performance expectations.

Mach Cooling, for example, integrates pultruded FRP frameworks into its cooling tower designs to ensure structural integrity, durability, and long-term reliability across global industrial projects.

Learn more at https://www.machcooling.com/

When selecting a supplier, look for:

Proven experience with pultruded FRP structures

Engineering-driven design capabilities

Customization for specific operating conditions

Strong industrial project references

A well-designed pultruded FRP cooling tower is only as good as the engineering behind it.

If traditional FRP cooling towers are reliable workhorses, pultruded FRP cooling towers are engineered heavy-duty performers. Stronger, more durable, and more consistent, they are built for long-term operation in demanding environments.

For facilities focused on reliability, lifecycle cost, and future-proof performance, pultruded FRP is not just an upgrade—it’s the smarter investment.

Are pultruded FRP cooling towers more expensive?

Initial costs may be slightly higher, but lifecycle costs are significantly lower.

Are they suitable for coastal or chemical environments?

Yes. Pultruded FRP excels in corrosive and high-humidity conditions.

Can pultruded FRP cooling towers be customized?

Absolutely. Structural design, airflow, and materials can all be tailored to project requirements.

Sustainable Cooling Towers: Balancing Evaporation And Water Use

Lightweight And Corrosion-Resistant Composites in Cooling Towers

Understanding Cooling Tower Collapse: Causes And Consequences

Filtration And Treatment Technologies for Blowdown Water Recycling

How To Choose The Right Closed Circuit Cooling Tower Manufacturer

Biggest Cooling Tower in The World: Engineering Scale, Design, And Global Impact

30 Ton Cooling Tower Explained: Capacity, Design, And Applications

Why Pultruded FRP Cooling Towers Outperform Traditional FRP Towers