We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-01-14 Origin: Site

When people think about cooling towers, they usually picture tall structures, roaring fans, or complex airflow systems. But down at the bottom lies a component that quietly keeps everything running smoothly—the cooling tower basin. Without a properly designed basin, even the most advanced cooling tower would struggle to operate efficiently.

In many ways, the basin is the heart of the cooling tower’s water circulation system. It collects, stores, and regulates cooled water before it begins the cycle all over again.

A cooling tower basin—also known as a cold water basin—is the section located at the bottom of the cooling tower where cooled water accumulates after flowing through the fill media. This water is then pumped back to chillers or industrial processes to absorb heat once again.

Think of it as a reset point in the cooling loop. Without this collection area, consistent circulation would be impossible.

The basin plays several critical roles at once:

Ensuring a stable water supply to circulation pumps

Preventing air entrainment and pump cavitation

Allowing sediment and debris to settle

Supporting water treatment and filtration systems

A poorly designed or poorly maintained basin can reduce cooling efficiency, increase energy consumption, and shorten equipment life.

Hot process water enters the cooling tower from the top and spreads across the fill. As air passes through, heat is removed. Gravity then pulls the cooled water downward into the basin, where it is collected for reuse.

The basin holds enough water to maintain steady pump suction even when system loads fluctuate. This buffer effect keeps the entire cooling system stable and responsive.

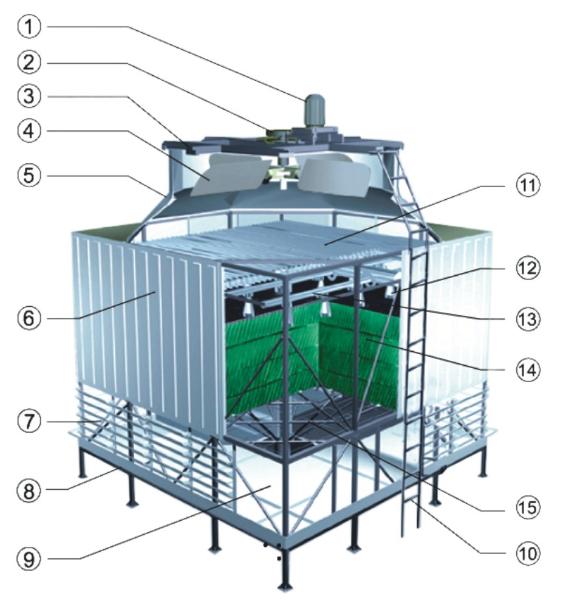

Concrete basins are commonly used in large, field-erected cooling towers.

Extremely durable

Suitable for very large volumes

Require proper sealing and waterproofing

Steel basins are widely used in packaged cooling towers.

Faster installation

Cost-effective

Often protected with galvanization or coatings

FRP (Fiber Reinforced Plastic) basins are ideal for corrosive environments.

Lightweight

Excellent corrosion resistance

Low maintenance requirements

Material selection directly affects basin lifespan and reliability. Common materials include:

Galvanized steel

Stainless steel

Reinforced concrete

FRP composites

Choosing the right material is like choosing the right foundation for a building—it determines how long everything above it will last.

Proper depth ensures adequate pump suction and prevents vortex formation. Sloped basin floors help guide sediment toward drain points, making cleaning easier.

Automatic level controls, overflow outlets, and make-up water valves keep the basin operating within optimal limits.

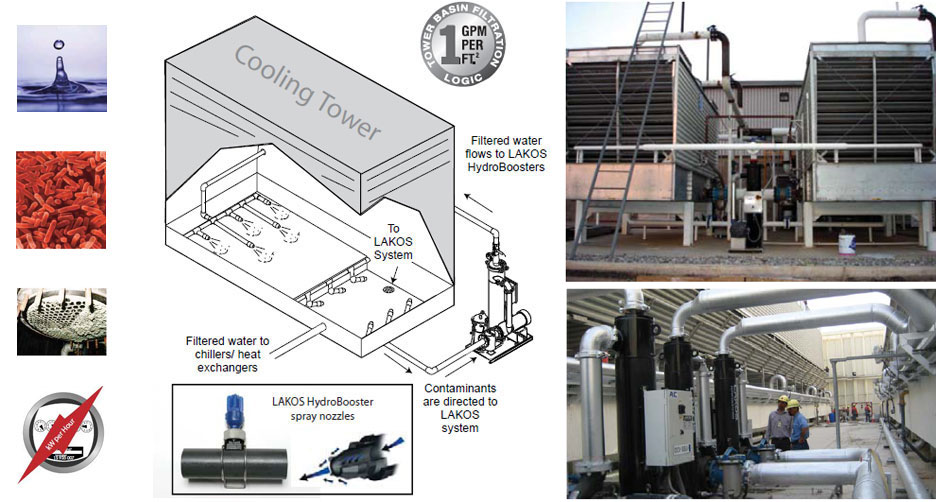

Evaporation losses are replaced with make-up water, while blowdown removes concentrated minerals. Both processes are managed directly within the basin.

Dust, debris, and biological growth naturally settle in the basin. Without cleaning, these contaminants can restrict flow and degrade water quality.

Improper materials or failed coatings can lead to corrosion, leaks, and structural damage—often hidden until serious problems arise.

Routine maintenance keeps basins performing at their best:

Scheduled cleaning and inspection

Monitoring of water chemistry

Prompt repair of coatings or seals

Ignoring basin maintenance is like skipping routine engine checks—it may work for a while, but failure is inevitable.

A clean, well-designed basin ensures smooth water circulation and stable pump operation. Conversely, a neglected basin increases energy use, accelerates wear, and reduces overall cooling efficiency.

HVAC systems prioritize compact design and consistent water levels

Industrial cooling towers require higher capacity, stronger materials, and resistance to chemicals and heat loads

Each application demands a tailored basin solution.

Today’s cooling towers often feature:

Integrated side-stream filtration

Advanced corrosion-resistant coatings

Automated water level and quality monitoring

These technologies significantly extend basin life and reduce operating costs.

Mach Cooling (https://www.machcooling.com/) applies practical engineering to basin design, focusing on:

Optimized hydraulic flow

Durable, application-specific materials

Easy access for inspection and maintenance

Their basin designs support long-term reliability across HVAC and industrial cooling tower applications.

The basin may be located at the bottom of the cooling tower, but its importance sits at the very top of system performance priorities. From water collection and storage to flow stability and maintenance efficiency, the basin is essential to reliable cooling tower operation.

By investing in proper basin design and working with experienced manufacturers like Mach Cooling, operators can achieve higher efficiency, lower maintenance costs, and longer equipment life.

What Is The Difference Between Field Erected And Modular Cooling Towers?

How To Define A Cooling Tower Based on Heat Transfer Principles

Noise Reduction And Maintenance Advantages in Cooling Towers

How Smart Monitoring Enhances Cooling Tower Water Efficiency

Cooling Tower Treatment Companies for Food And Beverage Industry