We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-01-14 Origin: Site

As cooling towers age, their performance often declines quietly—until energy bills spike, maintenance costs soar, or system reliability becomes a serious concern. Fortunately, replacing an entire cooling tower is no longer the only option. Today, retrofit solutions for aging cooling tower components offer a smarter, more economical way to restore performance, extend service life, and meet modern efficiency standards.

In this article, we’ll explore how cooling tower retrofits work, which components matter most, and how experienced manufacturers like Mach Cooling help facilities upgrade without starting from scratch.

Cooling towers operate continuously in demanding environments—heat, moisture, chemicals, and mechanical stress take their toll year after year. Over time, even well-maintained systems experience reduced heat rejection capacity and higher operating costs.

A retrofit focuses on upgrading critical components, not demolishing usable infrastructure. Think of it like renovating a building: strengthen the structure, modernize the systems, and dramatically improve performance—at a fraction of the cost of rebuilding.

A cooling tower retrofit involves replacing or upgrading worn, outdated, or inefficient components while keeping the existing tower framework intact. The goal is simple:

Restore original thermal performance

Improve energy and water efficiency

Reduce downtime and maintenance

Extend the tower’s operational life

Retrofits are widely used in industrial cooling towers, HVAC systems, power plants, and data centers.

If your cooling tower can no longer achieve design cold-water temperatures, aging fill media or airflow issues are often to blame.

Old fans, motors, and drift eliminators consume more power and waste more water than modern designs.

Corrosion, vibration, leaks, and structural fatigue are warning signs that key components are near failure.

Replacing an entire cooling tower is expensive, time-consuming, and disruptive. Retrofitting offers several advantages:

30–50% lower capital investment

Shorter shutdown periods

Faster ROI (often under 3 years)

Minimal civil or structural work

For most facilities, retrofitting strikes the perfect balance between cost and performance.

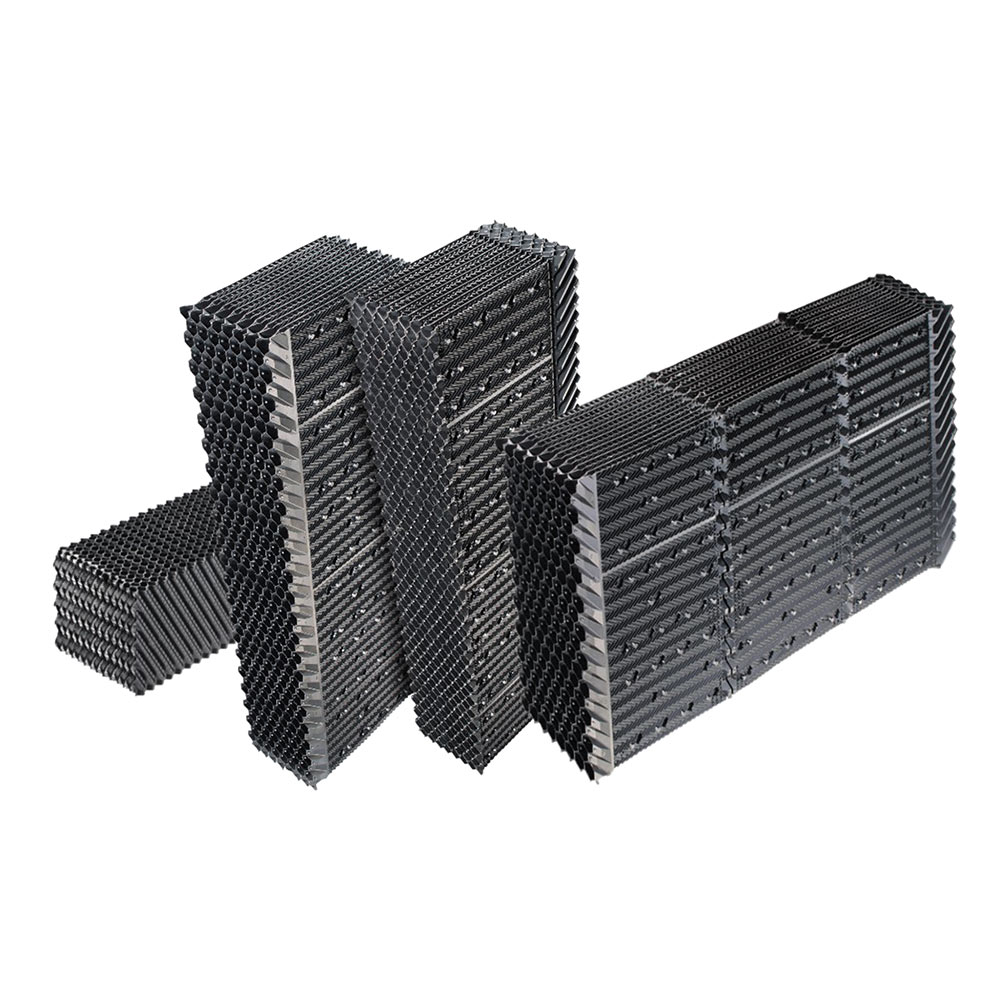

Modern PVC or polypropylene fill improves heat transfer efficiency, resists fouling, and restores lost cooling capacity.

High-efficiency axial fans and premium-efficiency motors significantly reduce power consumption while improving airflow stability.

Advanced drift eliminators minimize water loss, chemical carryover, and environmental impact.

New basin liners, strainers, and water distribution systems eliminate leaks, scaling, and uneven flow.

Fiber-reinforced plastic (FRP) components are increasingly used in retrofits due to their superior corrosion resistance, lighter weight, and longer lifespan compared to galvanized steel.

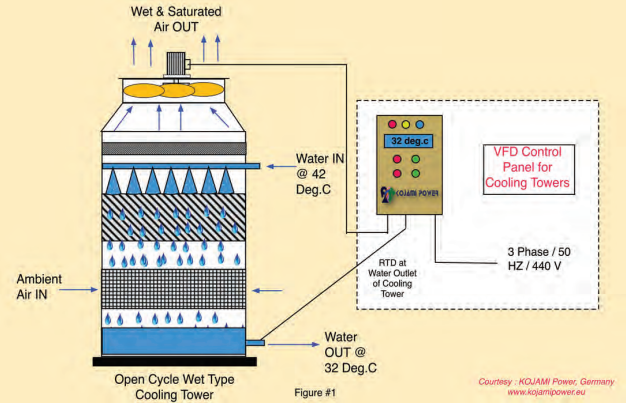

VFDs allow fan speed to adjust automatically based on thermal load, cutting energy consumption by up to 40%.

Optimized blade profiles move more air with less power—simple physics, big savings.

Advanced make-up water control, automated blowdown systems, and improved filtration reduce overall water usage while maintaining water quality and system reliability.

Industrial cooling tower retrofits prioritize durability, chemical resistance, and continuous operation. HVAC systems focus more on noise reduction, seasonal efficiency, and compact design. A successful retrofit must be tailored to the application—not generic.

Thermal performance testing, airflow analysis, and mechanical inspections identify performance bottlenecks.

Retrofit components are engineered to fit existing tower dimensions and operating conditions.

Most retrofits are completed during scheduled shutdowns, minimizing production or comfort disruptions.

Using incompatible materials

Oversizing fans or motors

Ignoring airflow balance

Skipping post-installation performance testing

Professional engineering makes all the difference.

Mach Cooling provides customized cooling tower retrofit solutions using high-quality materials, precision engineering, and global project experience. From fill replacement to full mechanical upgrades, Mach Cooling helps clients extend cooling tower life while improving efficiency and reliability.

Learn more at https://www.machcooling.com/.

Most cooling tower retrofits deliver:

Payback within 18–36 months

Lower maintenance and operating costs

Extended service life of 10–15 years

Few infrastructure upgrades offer this level of return.

Retrofitting prepares your cooling tower for:

Stricter energy and water regulations

Rising utility costs

Digital monitoring and smart control integration

It’s not just a repair—it’s a strategic upgrade.

Aging cooling towers don’t need to be replaced to perform like new. With the right retrofit solutions for aging cooling tower components, facilities can regain efficiency, reduce costs, and ensure long-term reliability.

In short, retrofitting gives your cooling tower a second life—and lets it perform at its full potential once again.

What Is The Difference Between Field Erected And Modular Cooling Towers?

How To Define A Cooling Tower Based on Heat Transfer Principles

Noise Reduction And Maintenance Advantages in Cooling Towers

How Smart Monitoring Enhances Cooling Tower Water Efficiency

Cooling Tower Treatment Companies for Food And Beverage Industry