We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-01-14 Origin: Site

When it comes to cooling tower performance, design and capacity often steal the spotlight. But behind every efficient and reliable system lies something far more fundamental—the materials used in its components. For Baltimore Aircoil cooling tower parts, material selection directly determines durability, efficiency, maintenance needs, and overall lifecycle cost.

Think of materials as the foundation of a building. If the foundation is weak, everything above it eventually cracks. The same logic applies to cooling towers.

Cooling towers operate in extreme conditions: continuous moisture, fluctuating temperatures, chemical exposure, and constant airflow. Materials must withstand corrosion, mechanical stress, and long-term fatigue—often all at once.

Choosing the wrong material is like wearing flip-flops on a construction site. It might work for a moment, but failure is inevitable.

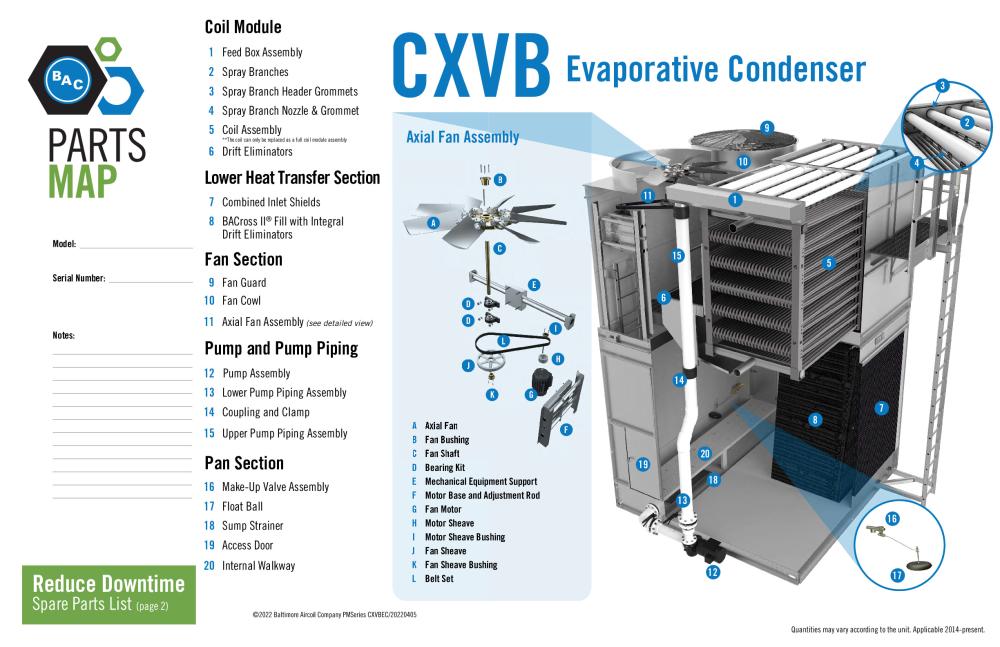

Baltimore Aircoil cooling towers consist of multiple functional parts, each exposed to different operating stresses:

Structural framework and casing

Cooling tower fill media

Drift eliminators

Spray nozzles and water distribution systems

Fans, motors, and mechanical drives

Each component demands a specific material solution tailored to its role.

Before diving into individual parts, let’s look at the most commonly used materials in cooling tower construction.

Galvanized steel is widely used for frames, panels, and cold water basins.

Key advantages:

Zinc coating provides basic corrosion protection

Strong and cost-effective

Suitable for standard HVAC environments

However, galvanized steel may struggle in aggressive water chemistry or coastal applications.

Stainless steel is often chosen for high-performance or corrosive environments.

Why stainless steel stands out:

Exceptional corrosion resistance

Long service life

Minimal maintenance requirements

While more expensive upfront, stainless steel often delivers lower total lifecycle costs.

FRP is a lightweight composite material commonly used in cooling tower panels and casings.

Benefits of FRP include:

Complete resistance to rust

Excellent chemical durability

Lightweight and easy to install

FRP is ideal where corrosion is a major concern.

Plastics dominate internal cooling tower components.

PVC (Polyvinyl Chloride): Excellent balance of cost, durability, and heat transfer

PP (Polypropylene): Superior resistance to high temperatures and aggressive chemicals

These materials are essential for long-term reliability inside the tower.

Now let’s break down material choices for specific Baltimore Aircoil cooling tower parts.

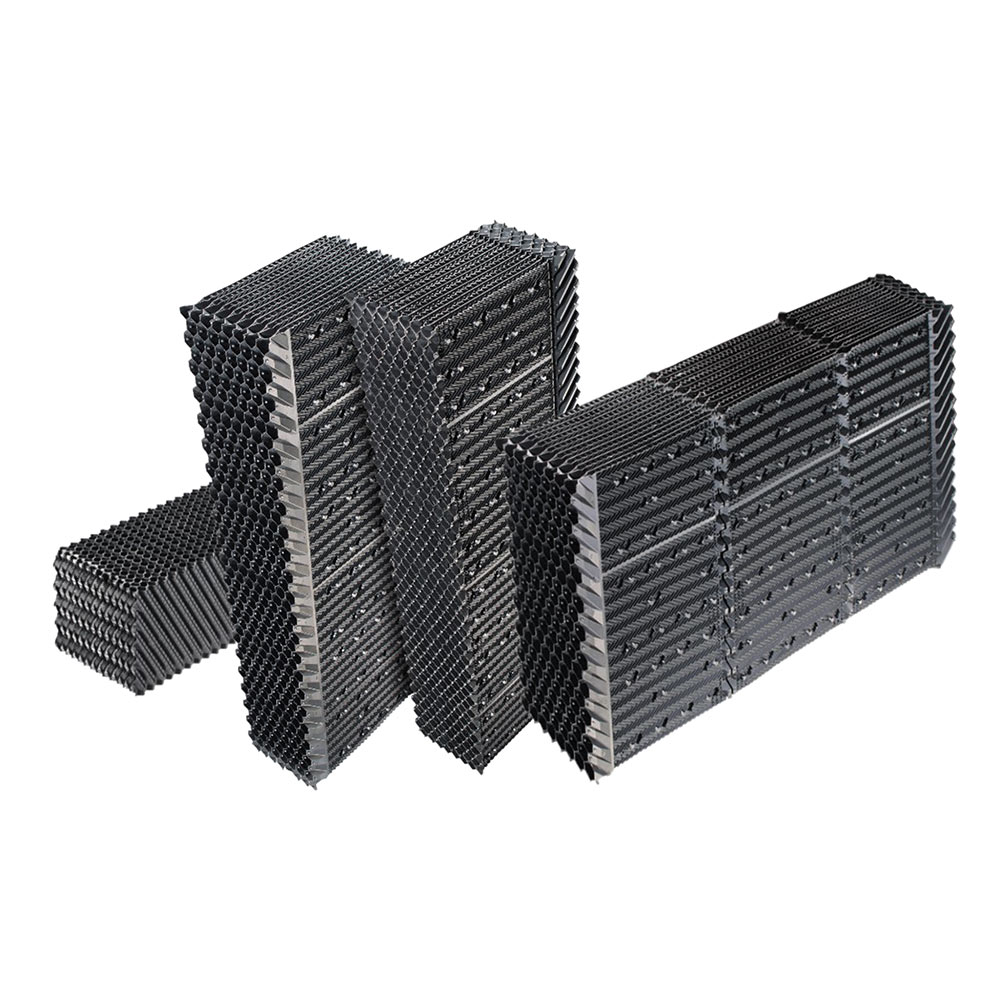

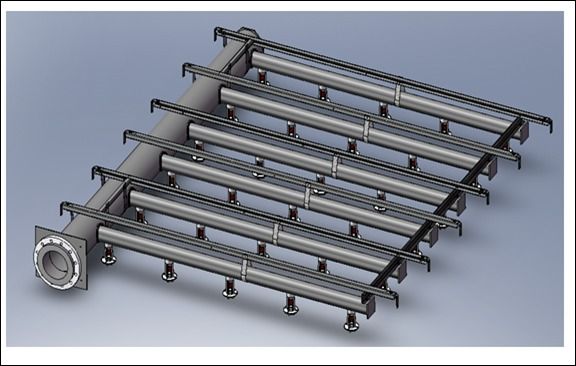

Fill media is the heart of heat exchange.

PVC fill is the industry standard because it offers:

High heat transfer efficiency

Resistance to biological fouling

Long operational life

PP fill is preferred for:

High-temperature applications

Chemically aggressive water conditions

Drift eliminators are usually manufactured from PVC or PP.

Material advantages include:

Lightweight structure

High water droplet capture efficiency

Resistance to UV and chemical exposure

Effective drift eliminators reduce water loss and help meet environmental regulations.

Spray nozzles must resist clogging, scaling, and corrosion.

Common materials include:

ABS plastic

PP plastic

Stainless steel (for high-pressure systems)

Plastic nozzles dominate due to their durability and ease of maintenance.

Fans and mechanical systems must balance strength and weight.

Typical materials include:

FRP fan blades

Aluminum hubs

Steel or stainless steel shafts

These combinations ensure stable operation and long service life.

Environmental factors play a huge role in material performance:

Coastal areas demand higher corrosion resistance

Industrial sites require chemical-resistant materials

Hot climates benefit from thermally stable plastics

Material selection should always match the operating environment.

Commercial HVAC systems: PVC, galvanized steel, FRP

Industrial cooling: Stainless steel, PP, FRP

Chemical and power plants: High-grade plastics and stainless steel

There is no “one-size-fits-all” solution—only the right material for the right job.

OEM parts are often expensive, but that doesn’t automatically mean they use superior materials. High-quality compatible replacement parts can meet or exceed OEM material standards when engineered correctly.

The real question is not who made the part—but what it’s made of.

Mach Cooling (https://www.machcooling.com/) specializes in material-optimized cooling tower parts compatible with Baltimore Aircoil systems.

Their approach includes:

Evaluating water chemistry and temperature

Matching materials to real operating conditions

Balancing performance, durability, and cost

This ensures long-lasting parts without unnecessary expense.

Better materials mean:

Less frequent maintenance

Reduced downtime

Lower long-term operating costs

In cooling towers, investing in quality materials always pays off over time.

Materials are the unsung heroes of Baltimore Aircoil cooling tower parts. From PVC fill media and PP drift eliminators to stainless steel structures and FRP components, every material choice directly affects performance and longevity.

By understanding these materials—and working with experienced manufacturers like Mach Cooling—operators can ensure reliable, efficient cooling tower performance for years to come.

Case Studies: Effective Makeup Water Management in Cooling Towers

What Is The Difference Between Field Erected And Modular Cooling Towers?

How To Define A Cooling Tower Based on Heat Transfer Principles

Noise Reduction And Maintenance Advantages in Cooling Towers

How Smart Monitoring Enhances Cooling Tower Water Efficiency

Cooling Tower Treatment Companies for Food And Beverage Industry