We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-01-13 Origin: Site

Buying a 240 ton cooling tower is not just another equipment purchase—it’s a long-term decision that directly affects energy efficiency, operational stability, and maintenance costs. At this capacity level, cooling towers are commonly used in industrial plants, large commercial HVAC systems, and energy-related facilities, where performance margins matter.

Choosing the wrong cooling tower is like buying the wrong engine for a heavy-duty truck. It may run, but it will never run efficiently. This article walks you through the most important factors to consider when buying a 240 ton cooling tower, using clear language, real-world logic, and practical insights.

Before comparing brands or prices, you need to understand your actual cooling requirement.

A 240 ton cooling tower is designed to reject heat equivalent to 240 refrigeration tons under specific design conditions. These conditions usually assume a standard range, approach, and wet-bulb temperature. In reality, your operating environment may differ significantly.

Always size the cooling tower based on:

Actual heat load

Local summer wet-bulb temperature

Required cold-water temperature

Oversizing wastes capital and energy. Undersizing leads to chronic performance problems.

Not all 240 ton cooling towers are built the same.

Induced draft cooling towers are the preferred choice for most modern applications. They offer better airflow distribution, reduced recirculation, and higher thermal efficiency compared to forced draft designs.

Counterflow towers are compact and thermally efficient, making them ideal where space is limited. Crossflow towers offer easier access for maintenance and simpler water distribution. The “best” choice depends on site layout and operational priorities.

Cooling towers operate outdoors year-round and must withstand harsh conditions.

Common materials include FRP, galvanized steel, and stainless steel. FRP structures are lightweight and corrosion-resistant, while metal structures provide high mechanical strength.

Poor water quality accelerates corrosion. Selecting corrosion-resistant materials at the beginning can significantly reduce lifecycle costs and unplanned downtime.

Thermal performance determines both cooling effectiveness and energy consumption.

A smaller approach temperature improves cooling performance but increases equipment size and cost. The key is finding the right balance for your application.

Efficient thermal design reduces fan power requirements and lowers long-term operating costs—an important consideration for a 240 ton system that runs continuously.

If the cooling tower is the body, the fan system is the lungs.

High-efficiency axial fans with optimized blade geometry deliver large airflow with minimal power consumption.

Industrial-grade motors with proper IP ratings and high efficiency classes ensure stable operation in humid and corrosive environments.

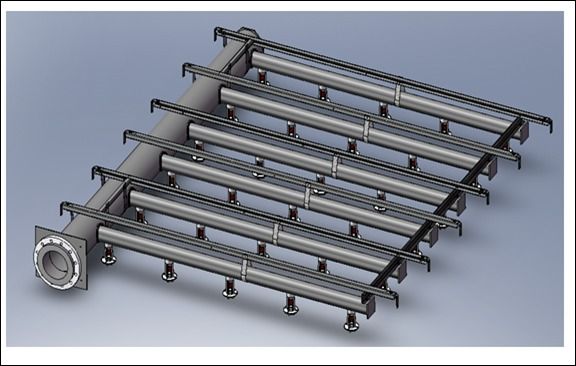

Uniform water distribution is essential for effective heat transfer.

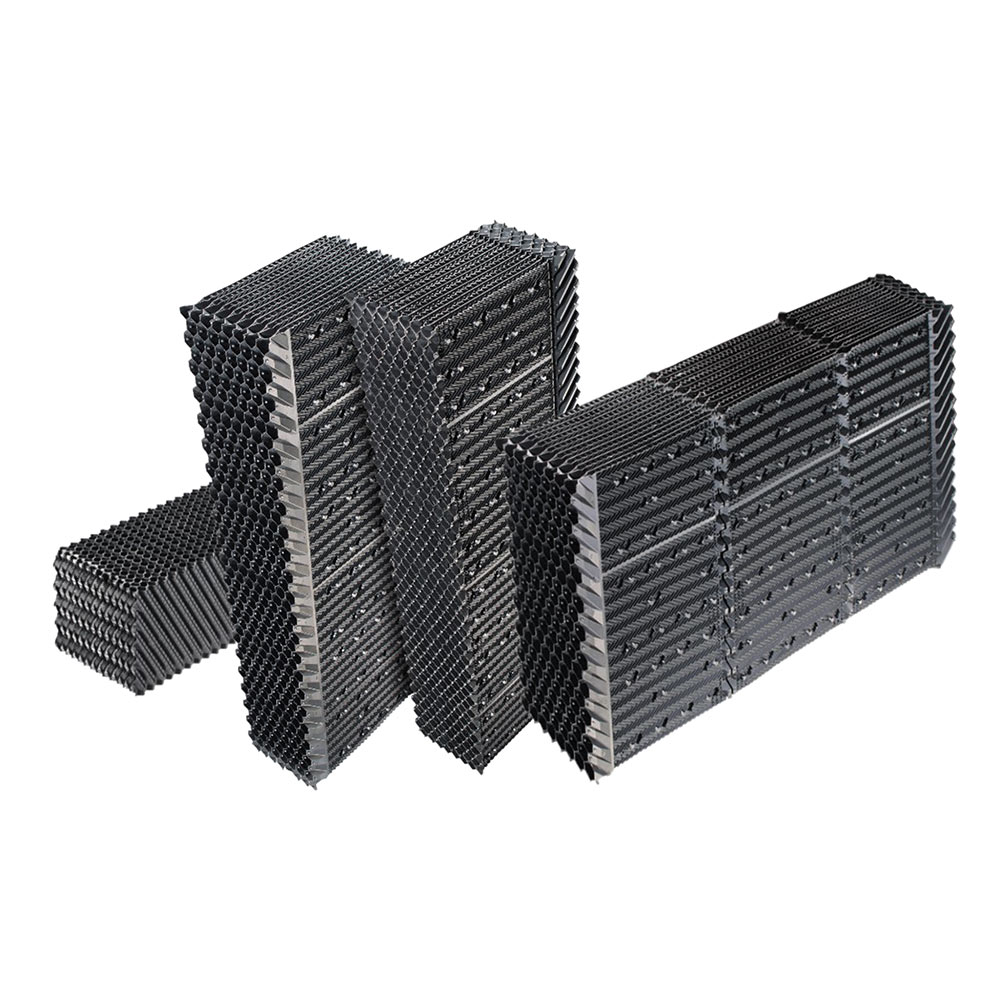

High-quality PVC or PP film fill maximizes surface contact between air and water while resisting fouling and deformation.

Noise regulations are becoming stricter, especially near residential or commercial areas. Low-noise fans, sound attenuators, and proper site planning should be considered early in the project.

A 240 ton cooling tower needs adequate airflow clearance, maintenance access, and structural support. Poor layout planning can severely reduce performance.

The purchase price is only part of the equation. Easy access to components, modular design, and straightforward maintenance procedures dramatically reduce total ownership cost.

Ensure the cooling tower complies with relevant standards such as CTI, ASHRAE, and local environmental regulations. Compliance protects both performance and project approval timelines.

A cooling tower is a system, not just a product. Engineering capability, customization experience, and after-sales support are just as important as specifications.

Mach Cooling (https://www.machcooling.com/) provides professionally engineered 240 ton cooling tower solutions designed for real operating conditions. With a strong focus on thermal efficiency, structural durability, and long-term reliability, Mach Cooling supports industrial and commercial projects with tailored cooling solutions.

A well-designed cooling tower allows future upgrades such as additional cells, higher-efficiency fans, or water-saving enhancements—without major reconstruction.

Before finalizing your purchase, confirm:

Accurate heat load calculations

Suitable tower type and configuration

Durable materials and efficient components

Reliable manufacturer support and warranty

Buying a 240 ton cooling tower is about choosing the right balance between performance, durability, and long-term cost efficiency. By carefully evaluating these key factors and working with an experienced manufacturer like Mach Cooling, you can ensure stable operation, lower energy consumption, and dependable cooling performance for years to come.

What Is The Difference Between Field Erected And Modular Cooling Towers?

How To Define A Cooling Tower Based on Heat Transfer Principles

Noise Reduction And Maintenance Advantages in Cooling Towers

How Smart Monitoring Enhances Cooling Tower Water Efficiency

Cooling Tower Treatment Companies for Food And Beverage Industry