We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-01-26 Origin: Site

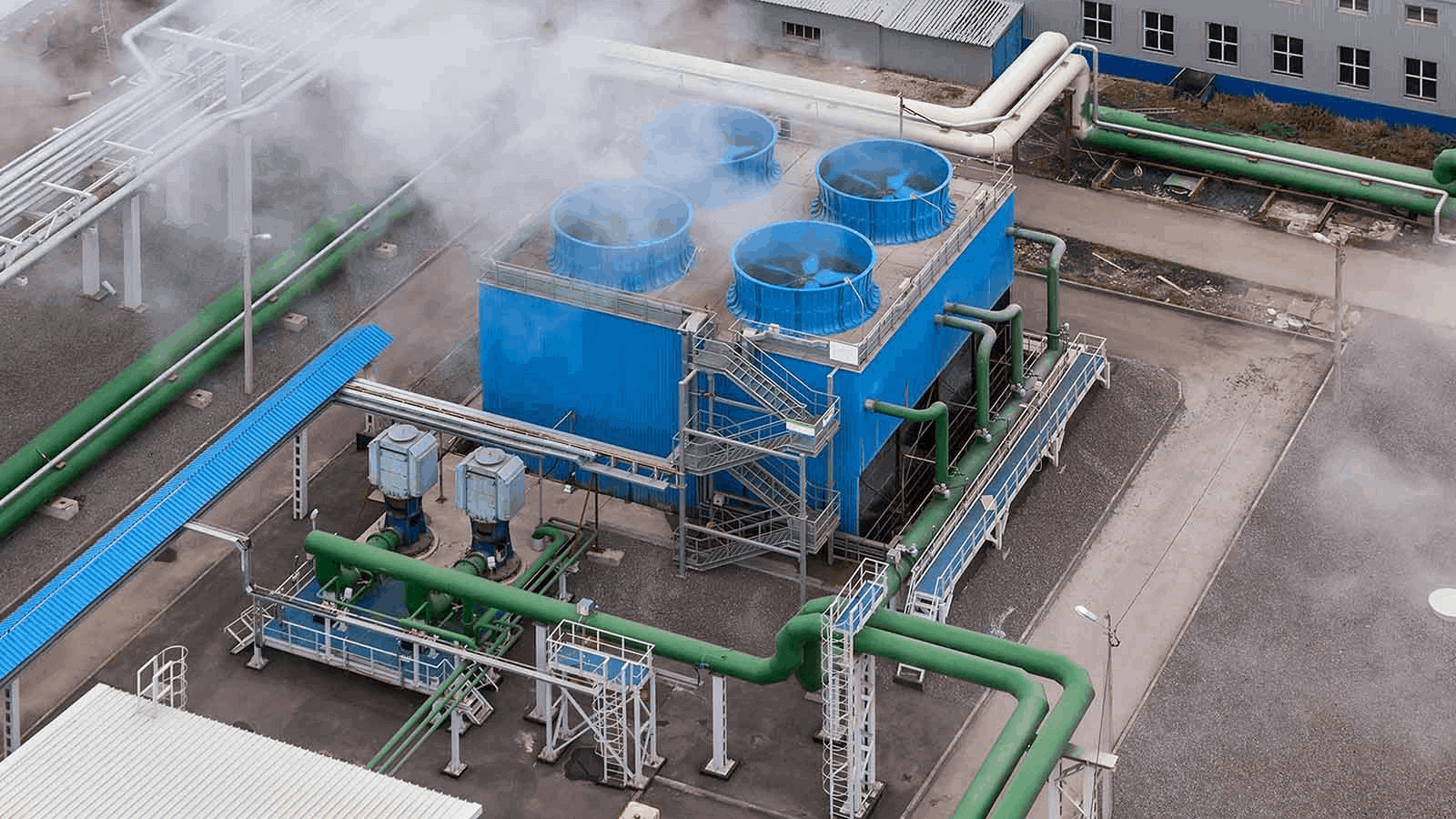

When it comes to industrial cooling, choosing the right cooling tower is crucial for both performance and efficiency. Midwest Cooling Tower has established itself as a trusted provider of reliable, efficient, and flexible cooling solutions across industries in the United States. In this guide, we will explore everything you need to know about Midwest Cooling Tower, including their working principles, components, applications, advantages, and why partnering with professional manufacturers like MACH Cooling ensures optimal results.

A Midwest Cooling Tower is an engineered system designed to remove unwanted heat from industrial processes, HVAC systems, and power plants. Unlike natural draft towers that rely on buoyancy, Midwest Cooling Towers often use mechanical draft systems, providing precise control over airflow and cooling performance.

Midwest Cooling Tower has decades of experience delivering durable and customizable cooling solutions to industrial clients throughout the Midwest and beyond. Their focus is on quality, efficiency, and modular design to meet the diverse needs of industrial operations.

Their products include:

Mechanical Draft Towers – induced draft and forced draft options

Natural Draft Towers for large-scale applications

Custom modular designs to meet specific plant requirements

Replacement parts and service solutions

At the heart of every cooling tower is a simple principle: transferring heat from water to air. Water flows over fill material while air passes through, causing a small portion of water to evaporate and removing heat from the remaining water.

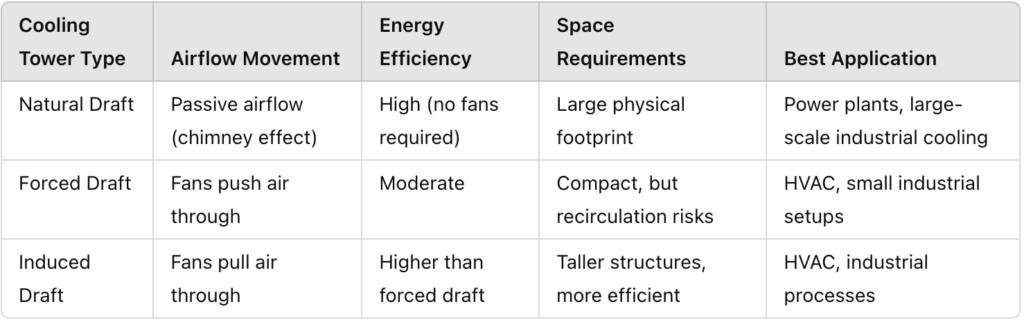

Mechanical Draft: Uses fans to actively push or pull air, offering high efficiency and consistent performance even in limited spaces.

Natural Draft: Relies on the stack effect for airflow; suitable for very large facilities but less adaptable to variable loads.

Imagine sprinkling water over a mesh while a fan blows air through it. The water cools as heat escapes into the air. This evaporative cooling is the principle behind Midwest Cooling Towers, delivering reliable and efficient temperature control for industrial processes.

Mechanical draft towers include fans and motors that regulate airflow for optimal cooling. Modern towers use variable speed drives to save energy during partial loads.

Fill materials increase water-air contact area. Midwest Cooling Tower typically uses PVC or PP fill, ensuring maximum thermal efficiency while resisting fouling and scale buildup.

The basin collects cooled water and recirculates it into the system. Proper design prevents sediment accumulation and ensures a steady supply of water to the plant.

These components reduce water loss and prevent debris or sunlight from entering, helping to maintain water quality and operational efficiency.

The combination of optimized airflow and advanced fill design allows Midwest Cooling Towers to remove heat effectively, ensuring industrial processes remain stable.

Midwest Cooling Towers can be scaled or customized based on plant requirements, making them suitable for expanding operations.

Variable-speed fans and optimized designs maintain stable outlet temperatures, even under fluctuating industrial loads.

Mechanical draft towers fit easily into tight plant layouts without sacrificing cooling capacity, making them ideal for space-limited industrial sites.

Used for condenser cooling and auxiliary systems, ensuring reliable thermal management under high heat loads.

Large commercial HVAC systems rely on Midwest Cooling Towers to maintain comfortable indoor environments efficiently.

Supports continuous chemical processes by providing precise and reliable cooling, critical for safety and production consistency.

Midwest Cooling Towers are designed for easy access to fans, fill, and basins, allowing quick inspection and maintenance.

Durable construction and corrosion-resistant materials ensure long-term performance with minimal downtime, a critical factor in industrial operations.

Select a tower based on heat load and process requirements, not just water flow, to ensure optimal cooling performance.

Options include FRP, galvanized steel, or stainless steel, depending on environmental conditions and chemical exposure.

Professional manufacturers like MACH Cooling deliver tailored Midwest Cooling Tower solutions, from design optimization and energy efficiency to installation support and after-sales service. Partnering with an experienced manufacturer guarantees long-term reliability and operational efficiency.

Midwest Cooling Tower provides efficient, reliable, and versatile cooling solutions for a wide range of industrial applications. From mechanical draft systems to modular designs, these towers help industries achieve consistent cooling, operational flexibility, and energy efficiency. By working with trusted manufacturers like MACH Cooling, you ensure your cooling system is optimized for performance, durability, and long-term value.

Cooling Tower for Sale – High Efficiency, Factory Direct Supply

Cooling Tower Capacity Vs Load: Matching Performance To Demand

Best Cooling Tower for Energy Efficiency And Low Operating Cost

Approach Temperature Vs Range in Cooling Towers: Key Differences

American Chillers And Cooling Tower Systems: Quality, Performance, And Reliability