We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-01-28 Origin: Site

In cooling tower design and operation, two technical terms often create confusion: approach temperature and range. They are closely related, yet fundamentally different. Understanding the difference between approach temperature vs range in cooling towers is essential for engineers, HVAC designers, and plant operators who want efficient, reliable, and cost-effective cooling systems.

This article explains these concepts in plain language, shows how they affect real-world performance, and highlights how experienced manufacturers like Mach Cooling design cooling towers to balance both parameters effectively.

Cooling towers exist for one simple reason: to remove heat. But how do we measure how well they do that job? That’s where performance metrics come in.

Among all cooling tower parameters, range and approach temperature are the most commonly referenced—and the most misunderstood. One tells you how much heat is removed. The other tells you how efficiently it is done.

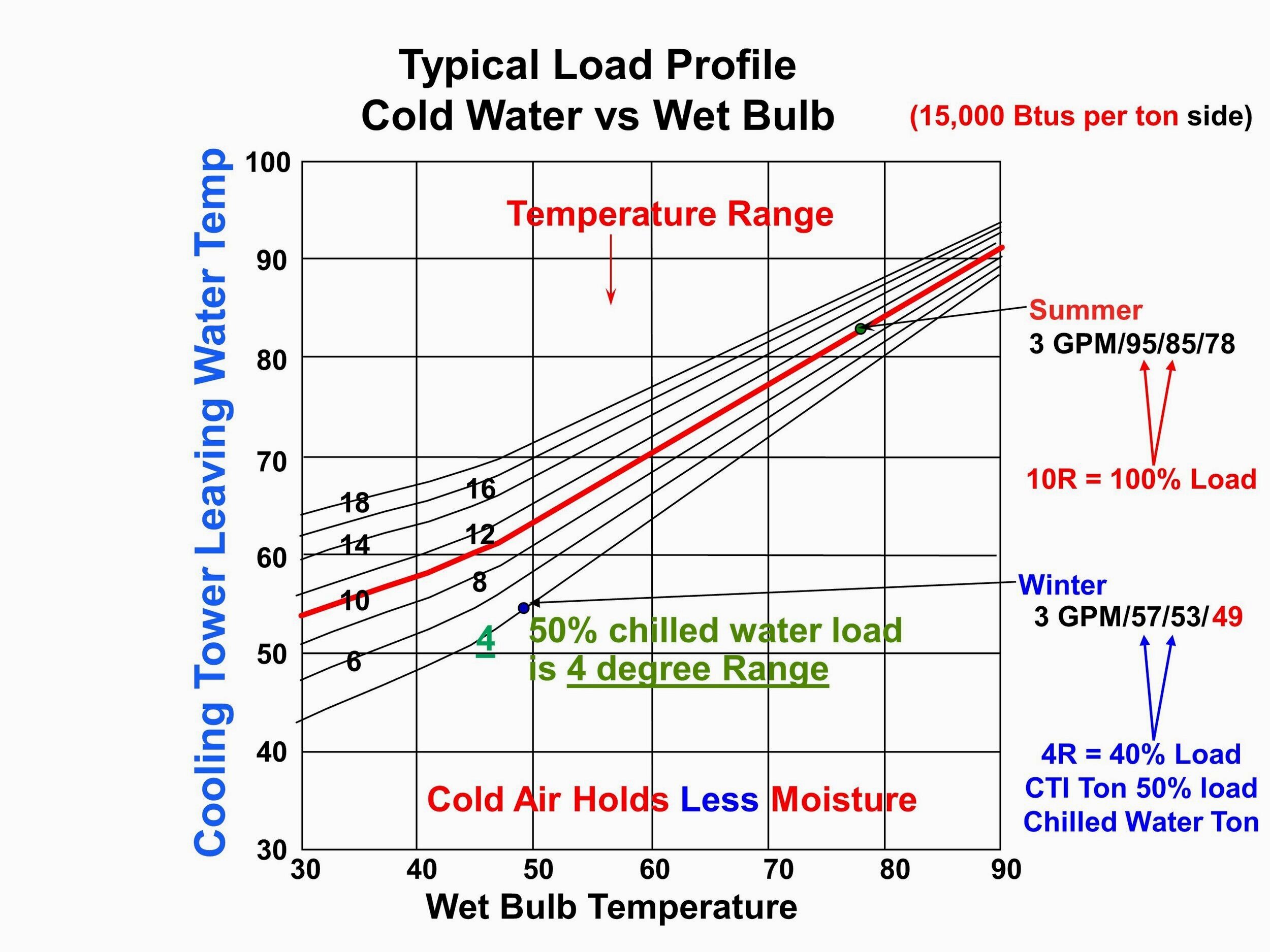

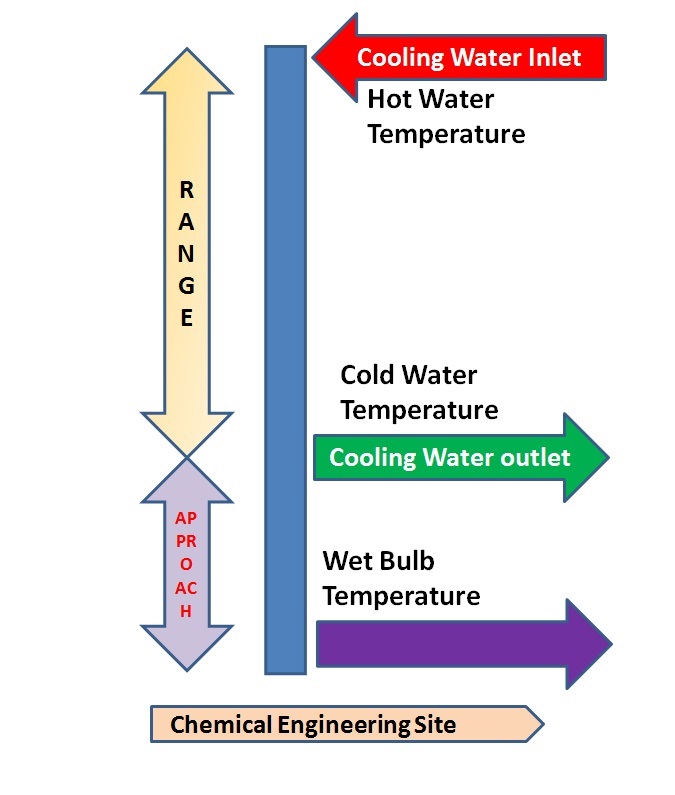

Cooling tower range is the temperature difference between the hot water entering the cooling tower and the cold water leaving it.

In simple terms, range represents how much heat the cooling tower removes from the circulating water.

The formula is straightforward:

Range = Hot Water Temperature – Cold Water Temperature

For example, if water enters the cooling tower at 42 °C and leaves at 32 °C, the range is 10 °C.

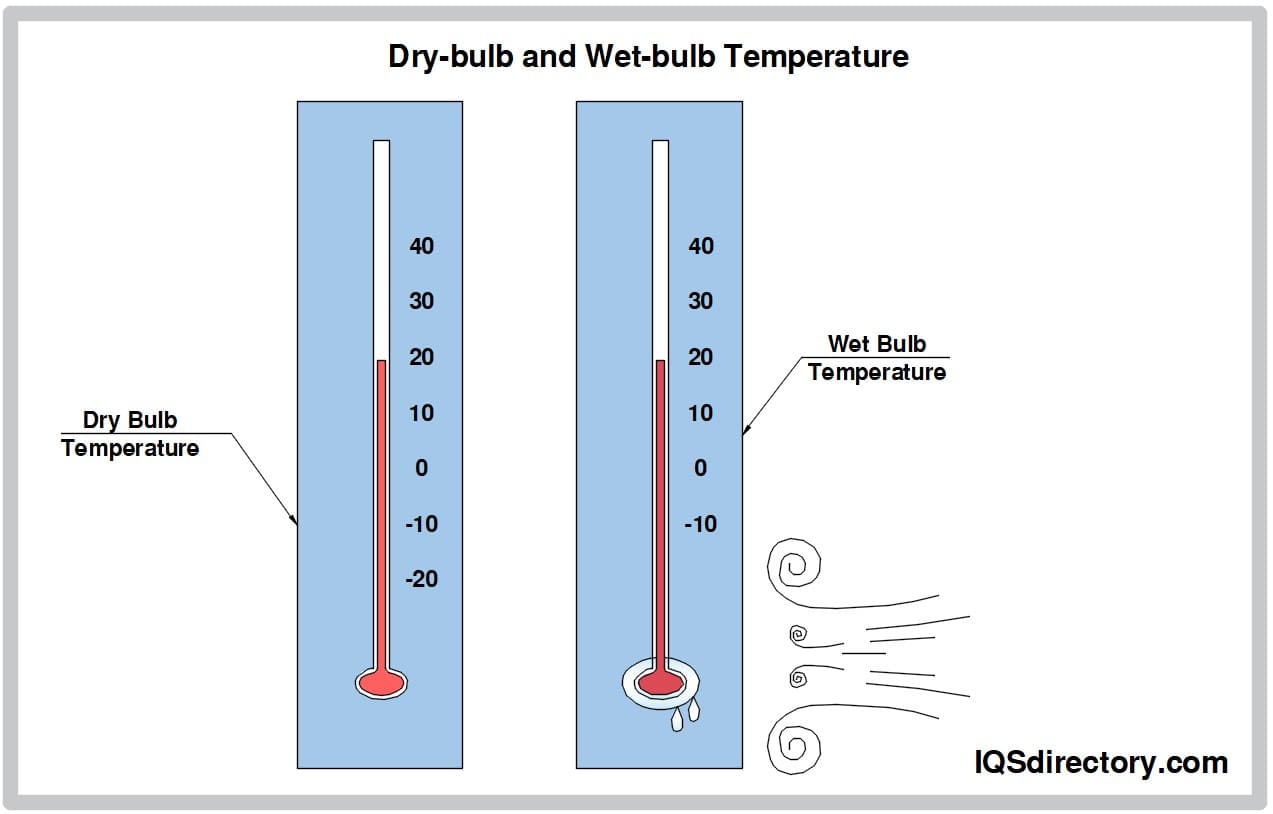

Approach temperature is the difference between the cold water temperature leaving the cooling tower and the ambient wet bulb temperature.

It indicates how close the cooling tower can cool water to the theoretical minimum set by the environment.

The calculation is:

Approach = Cold Water Temperature – Wet Bulb Temperature

If the cold water temperature is 32 °C and the wet bulb temperature is 27 °C, the approach temperature is 5 °C.

The simplest way to remember the difference is this:

Range measures heat removal quantity

Approach temperature measures cooling effectiveness

Range is influenced mainly by heat load, while approach reflects how efficiently the cooling tower performs.

You can increase range simply by adding more heat to the system. Reducing approach, however, requires better cooling tower design, improved airflow, and high-efficiency fill media.

While both parameters are important, approach temperature is the true indicator of cooling tower performance.

A lower approach temperature means:

Lower condenser water temperature

Improved chiller efficiency

Reduced energy consumption

More stable system operation

Range may look impressive in specifications, but approach temperature reveals the real performance capability.

In most industrial and HVAC applications:

Typical range: 5–15 °C

Typical approach temperature: 3–6 °C

Lower approach temperatures are achievable but require larger towers, better materials, and higher initial investment.

Wet bulb temperature represents the lowest temperature water can theoretically reach through evaporation. No cooling tower can cool water below this value.

That’s why approach temperature can never be zero—and why local climate plays a major role in cooling tower selection and design.

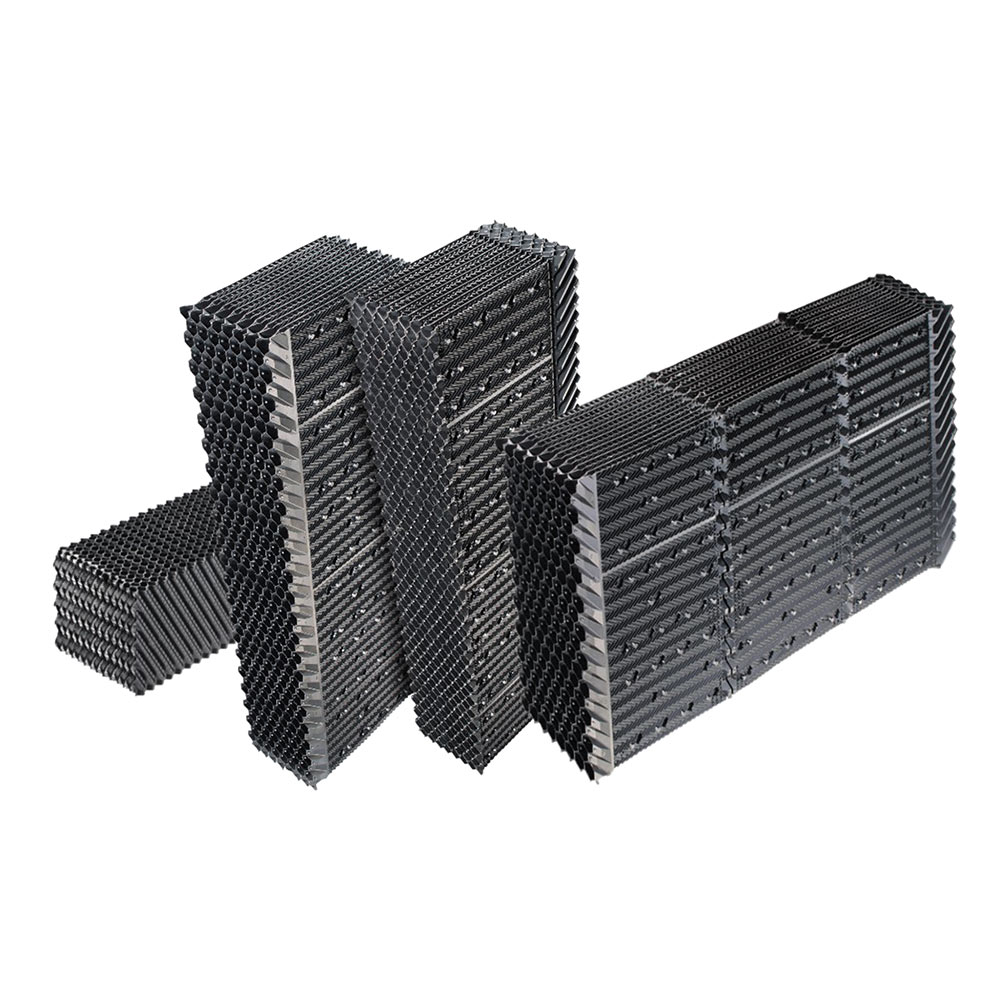

Achieving a lower approach temperature requires more heat transfer area. This usually means:

Larger cooling tower size

High-efficiency fill media

Optimized airflow design

Low approach designs come with trade-offs:

Higher fan power

Increased capital cost

More precise water distribution requirements

Experienced manufacturers address these challenges through smart engineering rather than oversizing.

Blocked airflow, fouled fill, uneven water distribution, or insufficient fan performance can all increase approach temperature—even if the system was designed correctly.

Regular inspection and maintenance are critical to preserving performance.

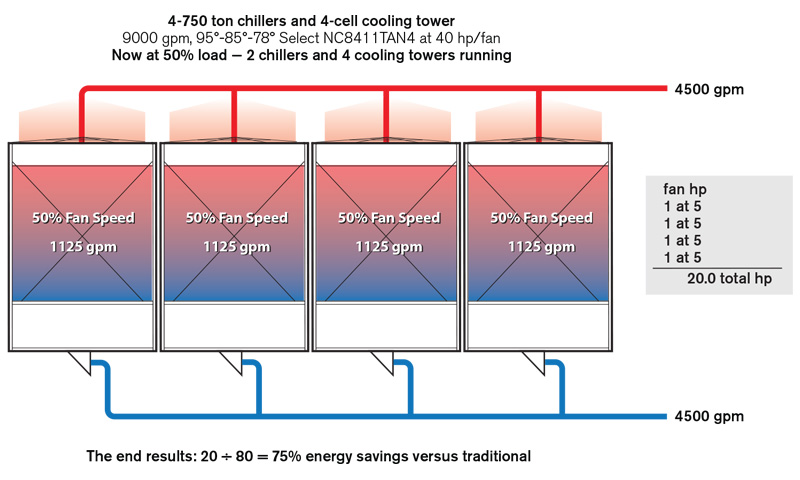

Cooling tower performance directly affects chiller efficiency. As a general rule, every 1 °C reduction in condenser water temperature can improve chiller efficiency by approximately 2–3%.

This makes approach temperature one of the most powerful variables for reducing overall system energy consumption.

A common mistake is focusing on range while ignoring approach temperature. This can result in a cooling tower that meets heat load requirements but operates inefficiently and drives up energy costs.

In practice:

Range tells you how much heat is removed

Approach tells you how well it is removed

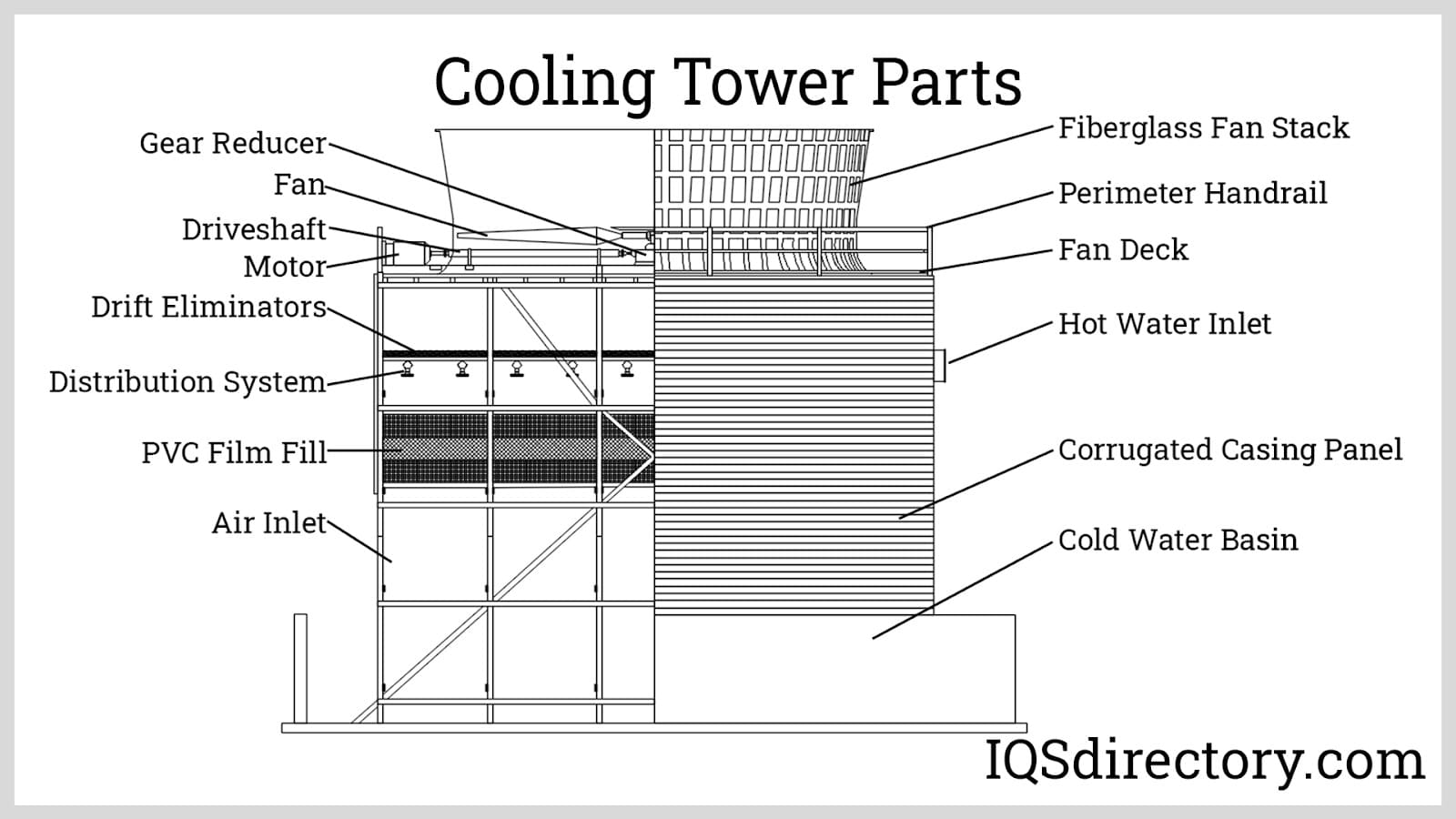

Manufacturers like Mach Cooling design cooling towers by balancing range and approach through:

Optimized fill and airflow configuration

Uniform water distribution systems

High-efficiency fan and motor selection

Application-specific material choices

This integrated approach ensures reliable, real-world performance rather than theoretical catalog values.

Learn more at https://www.machcooling.com/.

When selecting a cooling tower:

Define the required cold water temperature

Confirm local wet bulb temperature

Select a realistic approach temperature

Evaluate energy and lifecycle costs

Choose a manufacturer with proven engineering expertise

Understanding approach temperature vs range in cooling towers is essential for designing efficient and reliable cooling systems.

Range measures heat removal.

Approach temperature measures performance quality.

When cooling efficiency, energy savings, and long-term reliability matter, partnering with experienced manufacturers like Mach Cooling ensures your cooling tower system delivers consistent results—both in design and in operation.

Cooling Tower Capacity Vs Load: Matching Performance To Demand

Best Cooling Tower for Energy Efficiency And Low Operating Cost

Approach Temperature Vs Range in Cooling Towers: Key Differences

American Chillers And Cooling Tower Systems: Quality, Performance, And Reliability

How To Choose The Right Vibration Switch for Your Cooling Tower

How To Choose The Right 185 Ton Cooling Tower for Your Facility

Advantages of Precision Cooling Towers in Data Centers And Laboratories

Advantages of Mechanical Draft Cooling Towers in Industrial Cooling