We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-01-28 Origin: Site

In today’s industrial and commercial environments, cooling is no longer just a supporting function—it is a mission-critical system. From manufacturing plants to data centers and large HVAC projects, American chillers and cooling tower systems are widely recognized for their quality, performance, and long-term reliability.

This article explores how these systems work together, why they are trusted worldwide, and how choosing the right manufacturer—such as Mach Cooling—can make a measurable difference in efficiency, uptime, and lifecycle cost.

An industrial chiller is designed to remove heat from water or process fluids and maintain a stable temperature for equipment or buildings. American chillers are known for robust engineering, advanced controls, and stable performance under continuous operation.

Whether used for HVAC comfort cooling or industrial process cooling, chillers form the backbone of modern thermal management systems.

A cooling tower is responsible for rejecting heat from the system to the atmosphere through evaporative cooling. In water-cooled systems, cooling towers allow chillers to operate efficiently by maintaining optimal condenser water temperatures.

Think of the chiller as a heat collector and the cooling tower as a heat disposer. The chiller absorbs unwanted heat from the process or building, while the cooling tower releases that heat into the air. This partnership significantly improves system efficiency and reduces energy consumption.

Without a properly designed cooling tower, even the best chiller cannot perform at its full potential.

At the heart of every chiller are three critical components:

Compressors that drive the refrigeration cycle

Evaporators that absorb heat

Condensers that reject heat

American chiller designs emphasize durability, precise heat transfer, and stable operation across varying load conditions.

Modern chillers rely on intelligent control systems that automatically adjust capacity, optimize energy use, and protect equipment. These systems improve efficiency while reducing human error and unplanned downtime.

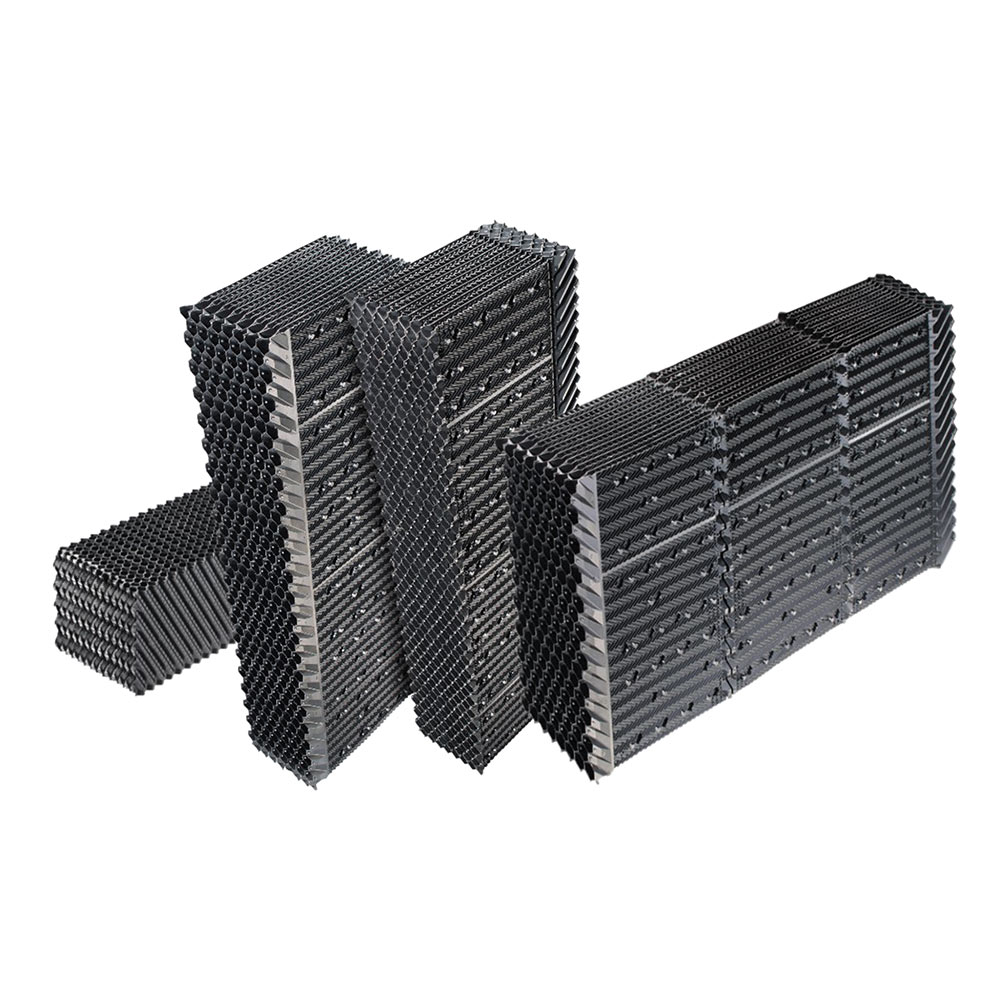

High-efficiency fill media maximizes the surface area for heat exchange, while drift eliminators reduce water loss and environmental impact. Quality materials in these components directly affect cooling efficiency and operating cost.

Uniform airflow and water distribution ensure consistent cooling performance. Well-designed fan systems also reduce energy consumption and operating noise.

Reputable American cooling systems are designed to meet ASHRAE and AHRI standards. These certifications ensure performance accuracy, energy efficiency, and long-term reliability—critical factors for industrial and commercial users.

The Coefficient of Performance (COP) measures how efficiently a chiller converts energy into cooling. Higher COP values mean lower energy bills and reduced environmental impact.

A high-quality system responds smoothly to changing loads instead of cycling aggressively. This stability protects components, improves comfort, and extends system lifespan.

Cooling systems operate in harsh, wet environments. Proper material selection is essential to prevent corrosion and structural failure.

Galvanized steel offers strength and cost efficiency

FRP (Fiberglass Reinforced Plastic) provides superior corrosion resistance and longer service life

Manufacturers like Mach Cooling select materials based on application conditions rather than one-size-fits-all solutions.

Stable cooling is critical for product quality and equipment protection in industries such as plastics, chemicals, and metallurgy. Reliable systems minimize downtime and improve production efficiency.

Data centers demand continuous cooling with zero tolerance for failure. American chillers and cooling towers provide the redundancy and reliability needed to maintain uptime and protect sensitive equipment.

Modern cooling tower designs reduce drift loss, optimize blowdown rates, and support water treatment strategies that minimize waste. Combined with high-efficiency chillers, these systems significantly reduce operating costs and environmental impact.

Routine inspections, proper water treatment, and seasonal maintenance are essential for long-term reliability. Preventive maintenance not only avoids costly breakdowns but also maximizes system efficiency over time.

Selecting the right manufacturer is just as important as choosing the right equipment. Mach Cooling provides integrated American chiller and cooling tower systems with:

Proven engineering expertise

Customized system design

Strict quality control

Long-term technical support

These strengths make Mach Cooling a reliable partner for industrial and commercial cooling projects worldwide.

When designed and manufactured correctly, American chillers and cooling tower systems deliver exceptional quality, performance, and reliability. They are not simply pieces of equipment, but long-term investments that protect operations, reduce energy costs, and support sustainable growth.

With experienced manufacturers like Mach Cooling, businesses can be confident that their cooling systems will perform efficiently today—and remain dependable for years to come.

Cooling Tower Capacity Vs Load: Matching Performance To Demand

Best Cooling Tower for Energy Efficiency And Low Operating Cost

Approach Temperature Vs Range in Cooling Towers: Key Differences

American Chillers And Cooling Tower Systems: Quality, Performance, And Reliability

How To Choose The Right Vibration Switch for Your Cooling Tower

How To Choose The Right 185 Ton Cooling Tower for Your Facility

Advantages of Precision Cooling Towers in Data Centers And Laboratories

Advantages of Mechanical Draft Cooling Towers in Industrial Cooling