We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-01-28 Origin: Site

Energy prices keep climbing. Water resources are under pressure. And equipment downtime is more expensive than ever. In this reality, choosing the best cooling tower for energy efficiency and low operating cost is no longer optional—it’s a smart business decision.

A cooling tower isn’t just a supporting component. It’s a long-term cost driver. The right design quietly saves money every day, while the wrong one drains budgets month after month. Let’s break down what really makes a cooling tower efficient, affordable to operate, and reliable over its entire lifespan.

Cooling towers operate continuously, often 24/7. Even small efficiency improvements can translate into massive savings over time. Lower fan power, reduced pumping energy, and improved heat rejection all work together to reduce electricity consumption.

Energy efficiency also improves system stability. When condenser water temperatures drop, chillers work less, compressors last longer, and maintenance costs shrink. Efficiency isn’t just about energy—it’s about protection.

Energy efficiency focuses on how much power the cooling tower consumes. Operating cost goes further—it includes electricity, water, chemicals, maintenance labor, and replacement parts.

The best cooling tower balances both. A highly efficient system that’s difficult to maintain isn’t truly cost-effective. Likewise, a cheap system with poor efficiency becomes expensive very quickly.

Smart buyers look beyond purchase price. A well-designed cooling tower can operate efficiently for 20 years or more. Over that time, energy and water costs far outweigh initial investment.

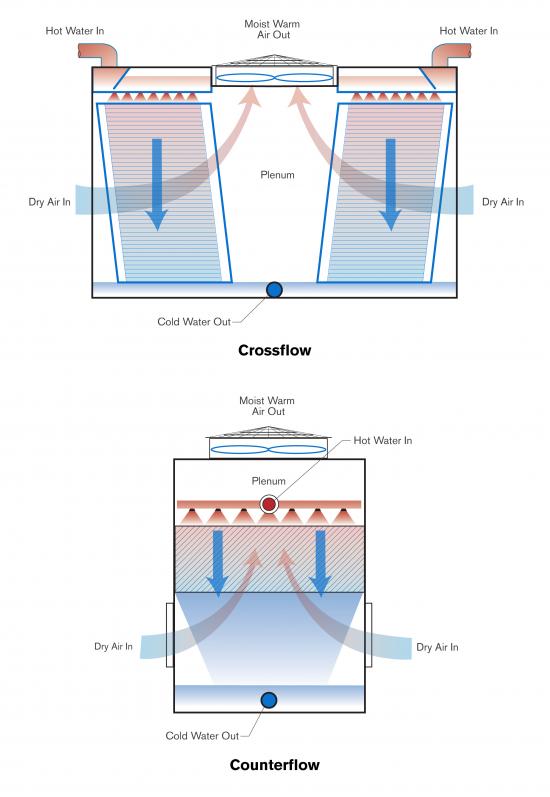

Counterflow cooling towers are often considered the most energy-efficient option. Air moves upward against the downward flow of water, creating excellent heat transfer.

Key advantages include:

Higher thermal efficiency

Lower fan power requirements

Smaller footprint for the same capacity

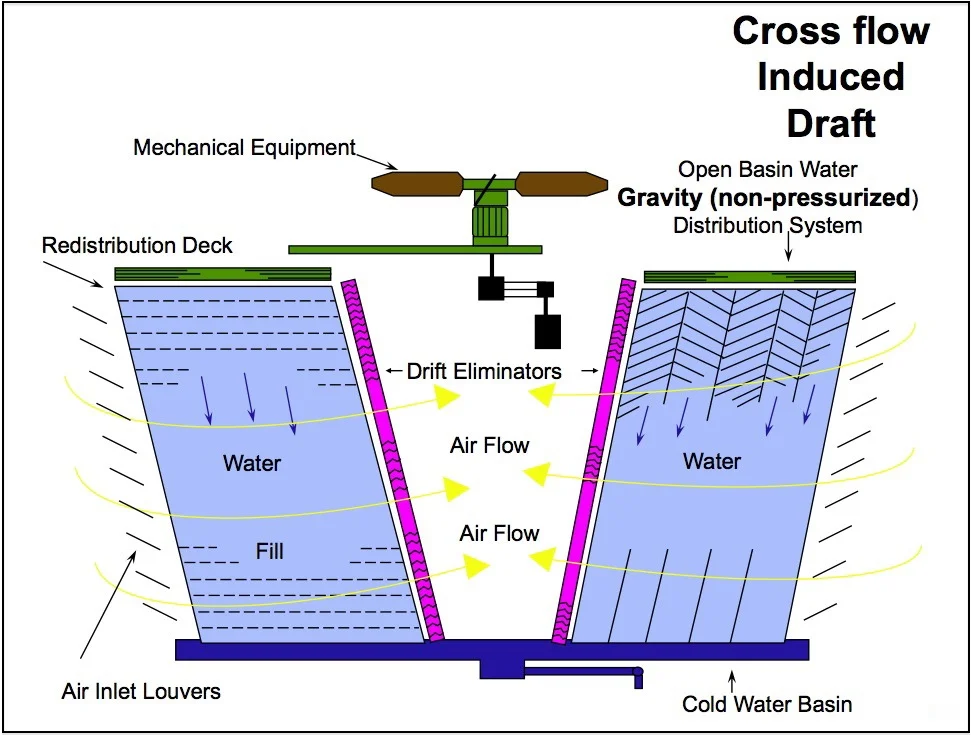

Crossflow cooling towers allow water to flow across incoming air. They are easier to maintain and typically require less pumping head, but may need larger size to match counterflow efficiency.

The “best” choice depends on space, climate, and operating priorities.

Fill media is the heart of a cooling tower. High-efficiency film fill increases the contact surface between air and water, improving heat rejection with less airflow.

Better heat transfer means fans don’t have to work as hard—saving energy every hour the system runs.

Fans are one of the largest power consumers in a cooling tower. Aerodynamic fan blades, optimized airflow paths, and efficient motors significantly reduce electricity usage.

VFD-controlled fans adjust speed based on real-time cooling demand. During part-load conditions, which occur most of the year, VFDs can reduce fan energy consumption by 30–50%.

Approach temperature is the difference between cold water temperature and ambient wet bulb temperature. A lower approach means the cooling tower delivers colder water.

Colder condenser water improves chiller efficiency. As a rule of thumb, every 1°C reduction in condenser water temperature can improve chiller performance by 2–3%.

Material choice plays a huge role in lifecycle cost.

FRP (Fiberglass Reinforced Plastic) cooling towers resist corrosion, require minimal maintenance, and perform well in harsh environments.

Galvanized steel cooling towers are strong and cost-effective but require proper water treatment to avoid corrosion.

Choosing the right material prevents premature failure and expensive repairs.

Water loss equals operating cost. High-performance drift eliminators minimize water carryover, while optimized blowdown control reduces chemical use and makeup water demand.

An efficient cooling tower saves both energy and water—double savings, same system.

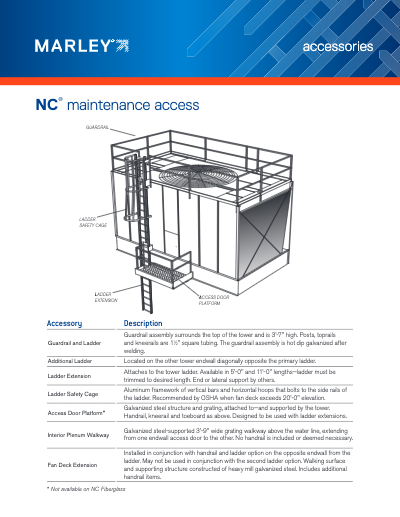

Maintenance-friendly cooling towers cost less to operate. Easy access to internal components shortens inspection time, while modular parts reduce downtime during repairs.

Less downtime means more uptime—and fewer headaches for operators.

Manufacturing processes depend on stable cooling. Energy-efficient cooling towers reduce production costs while protecting sensitive equipment from overheating.

In HVAC systems, cooling demand changes constantly. Efficient towers with VFD fans and optimized design handle part-load conditions with minimal energy waste.

Manufacturers like Mach Cooling focus on real-world efficiency, not just catalog numbers. Their engineering approach includes:

Optimized heat transfer and airflow design

Energy-efficient fans and motors

Application-specific material selection

Customized solutions based on climate and load

This focus on lifecycle performance ensures low operating cost and long-term reliability.

Learn more at https://www.machcooling.com/.

When selecting a cooling tower:

Analyze energy and water costs

Understand local wet bulb temperature

Set realistic approach temperature goals

Evaluate maintenance and lifecycle cost

Choose an experienced manufacturer

There is no single “best” cooling tower for everyone—only the best solution for your specific application.

The best cooling tower for energy efficiency and low operating cost is defined by smart engineering, quality materials, and thoughtful design—not by the lowest initial price.

When properly designed and built by experienced manufacturers like Mach Cooling, a cooling tower becomes a long-term asset—reducing energy bills, conserving water, and delivering reliable performance year after year.

A good cooling tower works.

A great cooling tower keeps saving you money.

Cooling Tower Capacity Vs Load: Matching Performance To Demand

Best Cooling Tower for Energy Efficiency And Low Operating Cost

Approach Temperature Vs Range in Cooling Towers: Key Differences

American Chillers And Cooling Tower Systems: Quality, Performance, And Reliability

How To Choose The Right Vibration Switch for Your Cooling Tower

How To Choose The Right 185 Ton Cooling Tower for Your Facility

Advantages of Precision Cooling Towers in Data Centers And Laboratories

Advantages of Mechanical Draft Cooling Towers in Industrial Cooling