We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-01-14 Origin: Site

Cooling towers are the silent workhorses behind industrial plants and HVAC systems. They continuously reject heat, keeping processes stable and buildings comfortable. But here’s the reality many operators learn the hard way: without proper chemical cooling tower water treatment, even the best cooling tower will struggle to perform.

Scale builds up, corrosion eats away at metal, bacteria multiply rapidly, and efficiency drops before anyone notices—until energy bills rise or equipment fails. That’s why chemical water treatment isn’t a luxury; it’s a necessity for both industrial cooling towers and HVAC cooling tower systems.

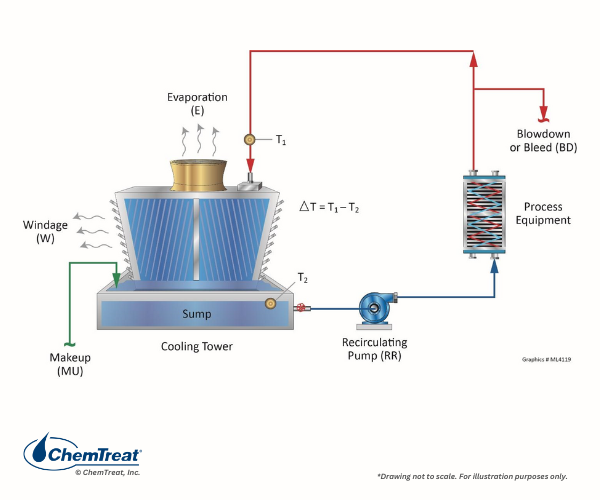

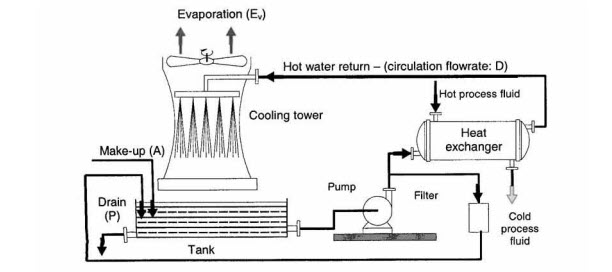

Cooling towers operate by evaporating water to remove heat. Evaporation is efficient—but it concentrates dissolved minerals and impurities. If left unmanaged, those impurities turn into serious operational problems.

Think of a cooling tower heat exchanger like a coffee mug. A clean mug holds heat evenly. Coat the inside with mineral deposits, and suddenly heat transfer slows down. Even a thin layer of scale can reduce heat transfer efficiency by more than 10%, forcing fans and pumps to work harder.

Poor water chemistry doesn’t just reduce performance—it shortens equipment life. Corroded pipes, clogged fill media, fouled heat exchangers, and unplanned shutdowns all stem from inadequate water treatment. In both industrial and HVAC applications, these failures quickly become expensive.

To understand chemical water treatment, you first need to understand what happens inside a cooling tower.

As water evaporates, minerals stay behind. Over time, their concentration increases. Chemical treatment works alongside controlled blowdown to keep mineral levels within safe limits, preventing scale and corrosion.

Every cooling tower starts with its make-up water. Hardness, alkalinity, silica content, and chlorides all influence which chemicals are required and how aggressive the treatment program must be.

Without chemical treatment, cooling towers face three major threats.

Calcium carbonate, calcium sulfate, and silica scale form hard, insulating layers on heat transfer surfaces. Scale acts like a winter coat on equipment—trapping heat where it shouldn’t be.

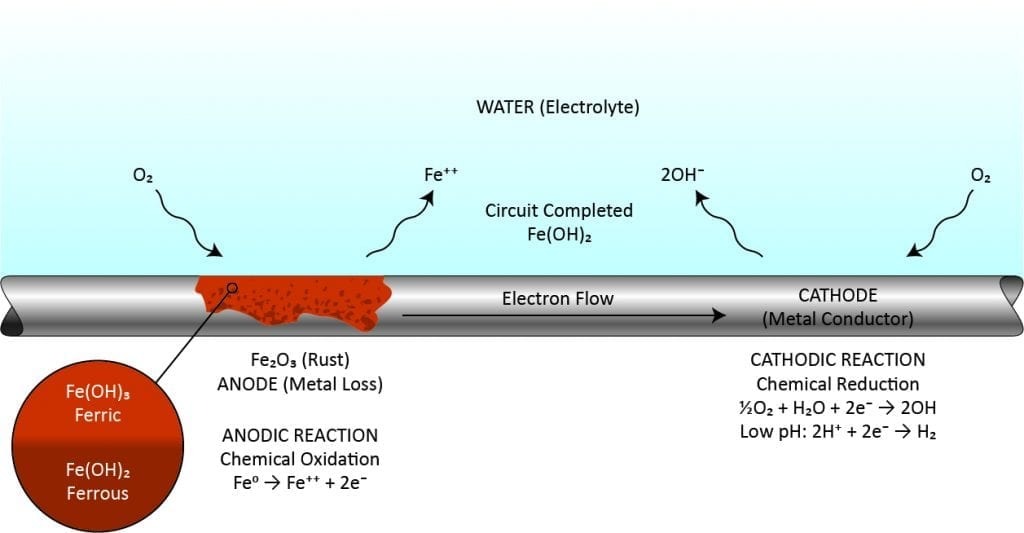

Oxygen, chlorides, and acidic conditions trigger corrosion in steel, copper, and other metals. Left unchecked, corrosion leads to leaks, structural damage, and early equipment failure.

Warm water and sunlight create the perfect environment for algae, bacteria, and biofilm. Microbial growth reduces flow, blocks nozzles, and creates health risks.

Chemical treatment doesn’t “purify” water—it controls how water behaves inside the system. A well-designed chemical program:

Keeps minerals suspended instead of forming scale

Forms protective films on metal surfaces

Controls bacteria, algae, and biofilm

Stabilizes pH and water chemistry

Scale inhibitors are the backbone of chemical water treatment.

Phosphonates interfere with crystal growth, stopping scale before it hardens on surfaces. They’re effective even at low concentrations.

Polymers act like traffic controllers, keeping particles dispersed and suspended until they’re removed by blowdown or filtration.

Corrosion inhibitors work by forming invisible protective layers on metal surfaces.

Some inhibitors slow metal oxidation, while others block corrosive reactions at the surface. The right balance depends on system materials and operating conditions.

Microbial growth is unavoidable—but manageable.

Chlorine and bromine act fast and are widely used for continuous microbial control.

These are applied periodically to prevent resistant organisms from developing and to break down established biofilm.

Consistent dosing is critical.

Small systems may rely on manual dosing, but most industrial and HVAC installations benefit from automated dosing systems. Automation improves accuracy, reduces labor, and prevents costly mistakes.

Blowdown is the pressure-release valve of cooling tower chemistry. Too little blowdown causes scale; too much wastes water and chemicals. The right balance protects both equipment and operating budgets.

While the chemistry principles are the same, application differs.

Industrial systems handle higher heat loads, harsher contaminants, and continuous operation. They require robust, closely monitored chemical programs.

HVAC systems prioritize stability, efficiency, and low maintenance. Treatment programs focus on long-term balance and simplified control.

The best chemical program works even better when paired with smart cooling tower design. Features like smooth basin surfaces, accessible internal components, and corrosion-resistant materials make chemical treatment more effective.

Experienced manufacturers such as Mach Cooling design cooling towers with water treatment in mind, reducing chemical demand and simplifying long-term maintenance.

Modern chemical cooling tower water treatment focuses on sustainability. Optimized programs reduce water consumption, minimize chemical discharge, and comply with environmental regulations—without sacrificing performance.

Test water regularly

Track trends, not just numbers

Adjust treatment based on seasonal changes

Coordinate cooling tower design with water treatment strategy

A well-designed cooling tower reduces water loss, chemical usage, and maintenance costs from day one. Manufacturer experience matters just as much as chemical selection.

By combining advanced structural design, durable materials, and water-treatment-friendly layouts, Mach Cooling helps industrial and HVAC systems achieve reliable performance, lower operating costs, and longer service life.

Chemical cooling tower water treatment is the foundation of efficient heat rejection. When chemistry, design, and operation work together, cooling towers don’t just survive—they perform at their best year after year.

If you want your cooling tower to run clean, efficient, and reliable, water treatment isn’t optional—it’s essential.

Case Studies: Effective Makeup Water Management in Cooling Towers

What Is The Difference Between Field Erected And Modular Cooling Towers?

How To Define A Cooling Tower Based on Heat Transfer Principles

Noise Reduction And Maintenance Advantages in Cooling Towers

How Smart Monitoring Enhances Cooling Tower Water Efficiency

Cooling Tower Treatment Companies for Food And Beverage Industry