We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-01-27 Origin: Site

When running a data center or laboratory, every degree of temperature stability matters. That’s where precision cooling towers come into play. Unlike standard industrial towers, they are designed for ultra-stable temperature control, low energy consumption, and highly reliable operation. In this article, we’ll explore how precision cooling towers help maintain optimal conditions, their main advantages, and why choosing a trusted manufacturer like MACH Cooling can make all the difference.

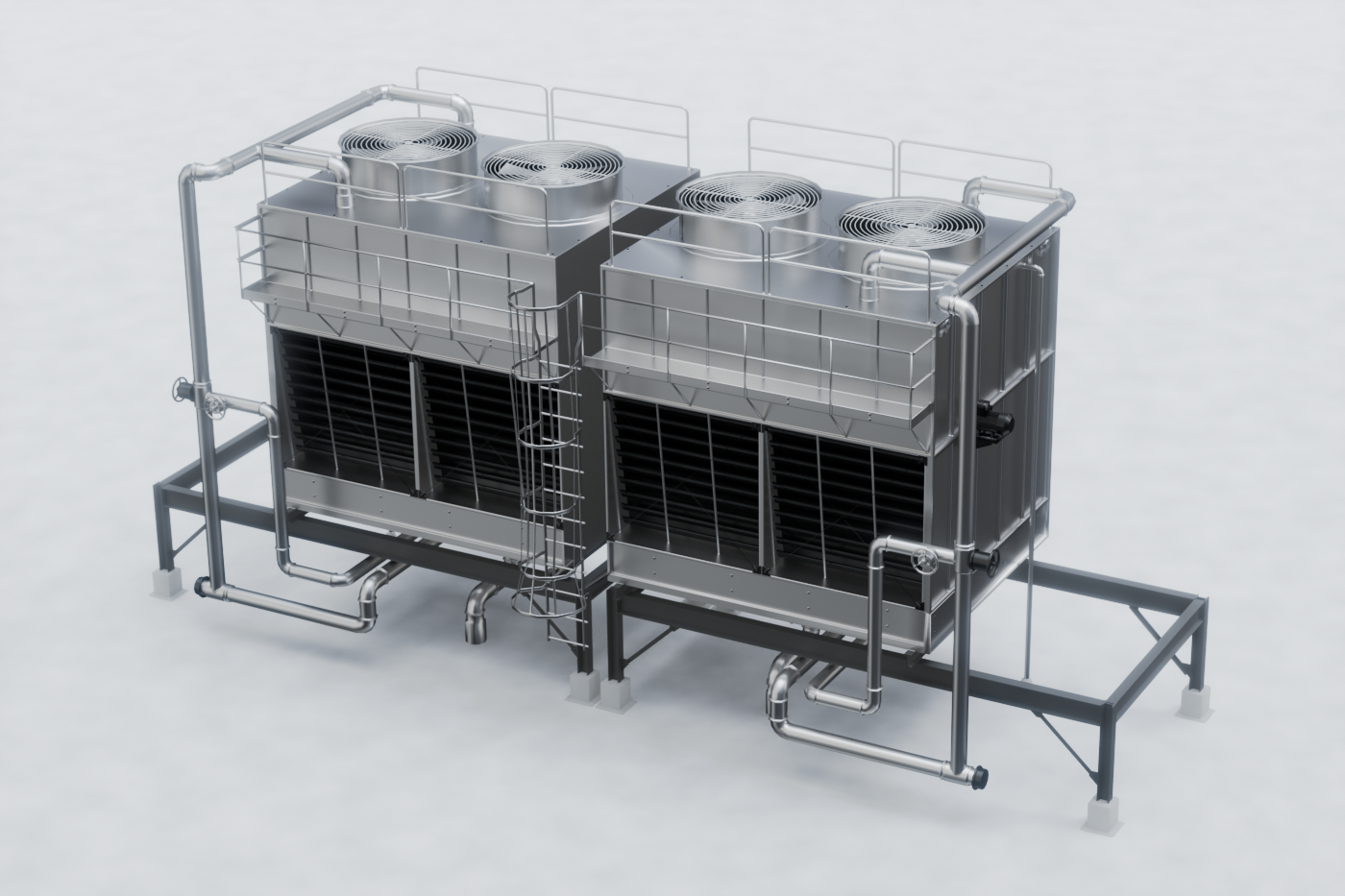

Precision cooling towers are specialized evaporative cooling systems designed for applications where temperature and humidity must be tightly controlled. They are widely used in data centers, laboratories, semiconductor fabrication, and high-tech industries.

A precision cooling tower is defined by:

Temperature control accuracy within ±1°C or better

Stable airflow and water distribution

Advanced mechanical or induced draft fans

Compact footprint suitable for sensitive environments

Unlike standard cooling towers used for industrial processes, precision towers:

Maintain consistent water temperature for sensitive equipment

Reduce vibration and noise that could interfere with lab instruments

Offer modular designs that fit space-limited facilities

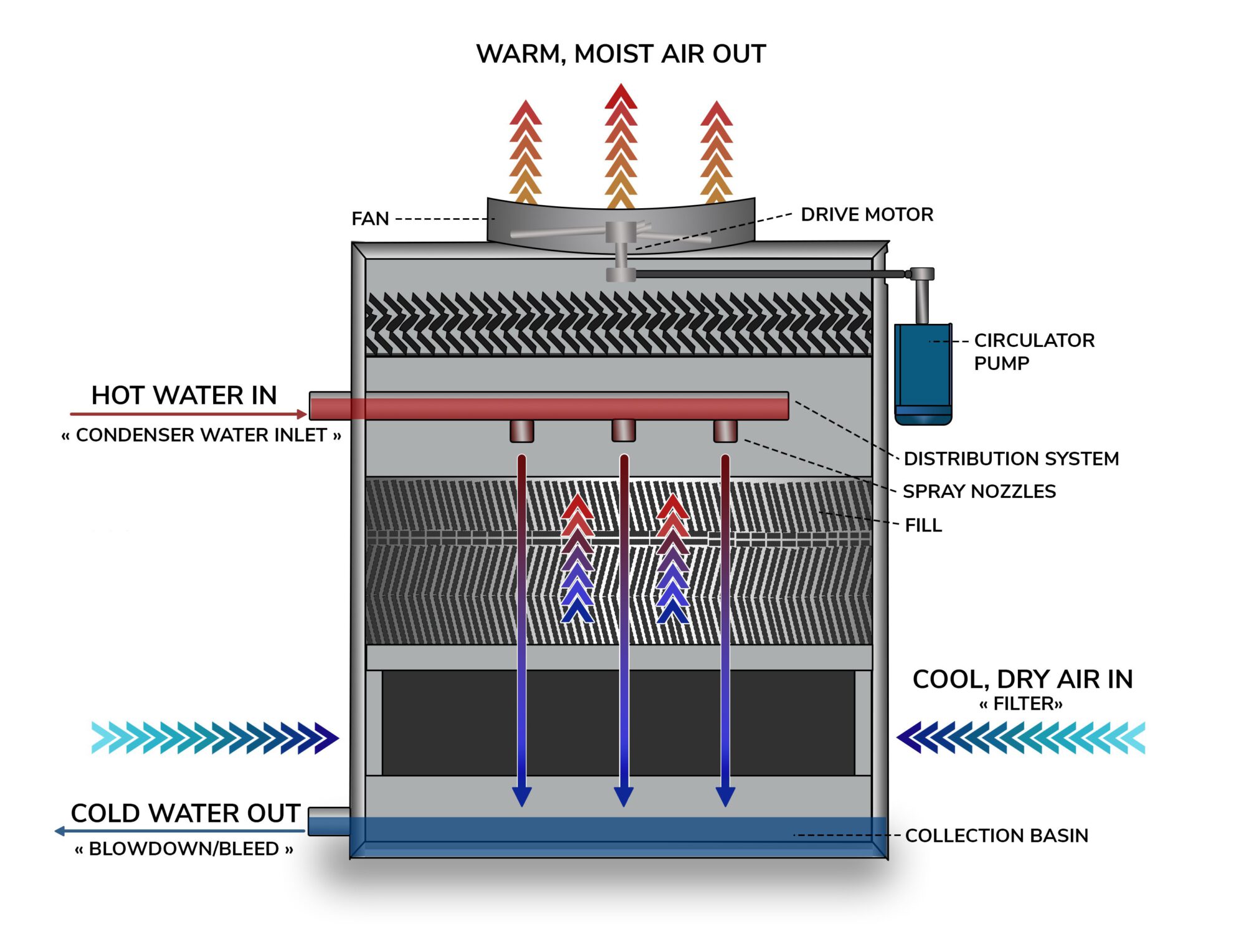

Most precision cooling towers use mechanical draft systems to actively move air across the fill media. This ensures precise control of air velocity, which is critical for consistent cooling performance.

The towers operate on the evaporative cooling principle: hot water flows over fill media, air passes through, and a small portion of water evaporates, removing heat from the system. Think of it like a finely tuned sweating system for your lab or server room.

Precision cooling towers use variable-speed fans that adjust airflow based on real-time temperature demands. This not only maintains consistent cooling but also reduces energy consumption.

The fill provides maximum water-air contact, enhancing heat transfer efficiency while minimizing hotspots. Modern precision towers often use PVC or PP fills resistant to fouling and scaling.

The basin collects cooled water for recirculation, while drift eliminators reduce water loss and prevent aerosol formation. Proper design ensures water efficiency and system longevity.

Precision cooling towers often integrate advanced digital control systems, monitoring water temperature, flow, and fan speed to maintain tight tolerances required in labs and data centers.

Servers are highly sensitive to temperature fluctuations. Precision cooling towers provide consistent chilled water temperatures, preventing overheating and potential hardware failure.

Variable-speed fans and optimized fill design lower energy use, which can significantly reduce electricity costs in large facilities.

Many data centers operate in urban or retrofit spaces. Precision towers are smaller and modular, fitting into tight mechanical rooms without sacrificing performance.

High-precision lab instruments require stable environmental conditions. Precision towers maintain exact temperature and humidity control, ensuring accurate results.

Low-noise fans and vibration-reducing mounts protect sensitive experiments and instruments from interference.

When experiments run for weeks or months, temperature consistency is critical. Precision towers provide this stability, avoiding costly sample loss or invalid results.

Precision cooling towers outperform standard towers in:

Temperature accuracy

Stability under fluctuating loads

Noise and vibration control

Compactness and adaptability

Used for drug production where temperature-sensitive reactions must remain stable.

Precision towers support wafer fabrication processes that require exact thermal control.

Components are designed for accessibility, making inspections and routine maintenance quick and safe.

Durable materials and efficient operation reduce wear and tear, ensuring years of reliable performance.

Always match tower capacity to actual heat load, not just nominal flow rate.

Materials like FRP, stainless steel, and high-grade plastics ensure durability in demanding environments.

Manufacturers like MACH Cooling deliver custom precision cooling solutions tailored to your facility’s size, load, and environmental requirements. Their expertise ensures energy efficiency, reliable performance, and professional support.

Precision cooling towers are indispensable for data centers, laboratories, and high-tech industries. They provide stable temperature control, energy efficiency, compact design, and reliable performance, essential for sensitive equipment and processes. Partnering with trusted manufacturers like MACH Cooling guarantees your facility benefits from long-term operational reliability and optimized cooling solutions, keeping your equipment and experiments safe and efficient.

Cooling Tower Capacity Vs Load: Matching Performance To Demand

Best Cooling Tower for Energy Efficiency And Low Operating Cost

Approach Temperature Vs Range in Cooling Towers: Key Differences

American Chillers And Cooling Tower Systems: Quality, Performance, And Reliability

How To Choose The Right Vibration Switch for Your Cooling Tower

How To Choose The Right 185 Ton Cooling Tower for Your Facility

Advantages of Precision Cooling Towers in Data Centers And Laboratories

Advantages of Mechanical Draft Cooling Towers in Industrial Cooling