We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-01-27 Origin: Site

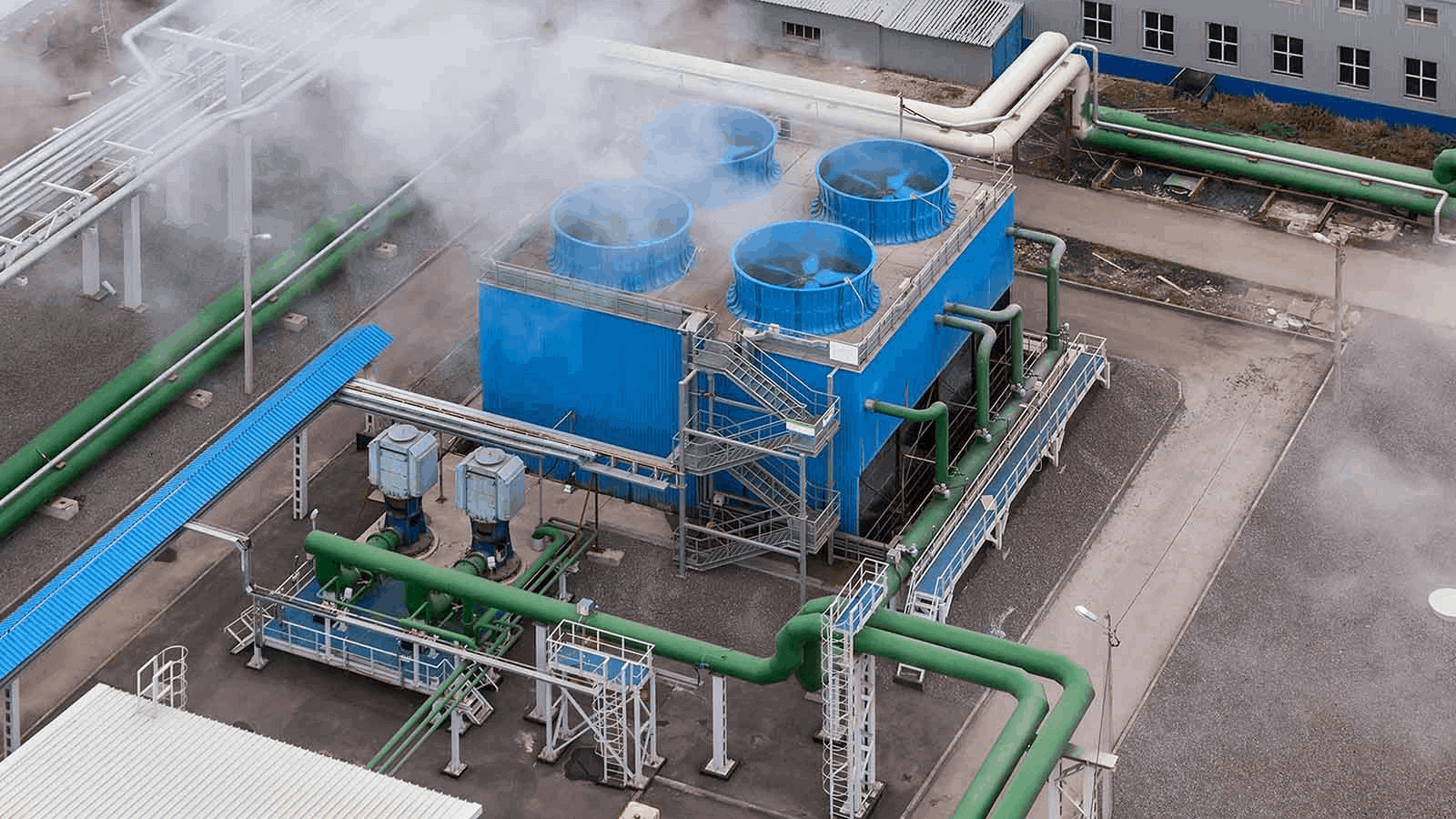

When industrial processes generate heat, that heat has to go somewhere. And in many cases, the most practical, efficient, and controllable solution is a mechanical draft cooling tower.

From power plants to manufacturing facilities, mechanical draft cooling towers have become the backbone of modern industrial cooling. Why? Because they offer flexibility, efficiency, and reliability that many other cooling systems simply can’t match.

In this article, we’ll break down the key advantages of mechanical draft cooling towers in industrial cooling, explain how they work, and show why professional manufacturers like MACH Cooling continue to optimize this technology for today’s demanding applications.

Industrial cooling isn’t just about lowering water temperature—it’s about keeping entire systems stable, safe, and efficient.

A mechanical draft cooling tower gives operators control. Control over airflow. Control over performance. Control over operating conditions. And in industrial environments where heat loads fluctuate constantly, that control makes all the difference.

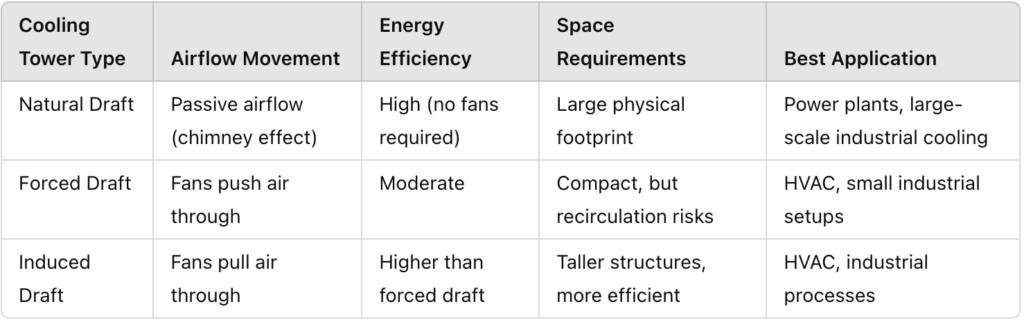

A mechanical draft cooling tower uses fans to move air through the tower. Unlike natural draft towers that rely on height and buoyancy, mechanical draft towers actively pull or push air, ensuring consistent airflow regardless of weather conditions.

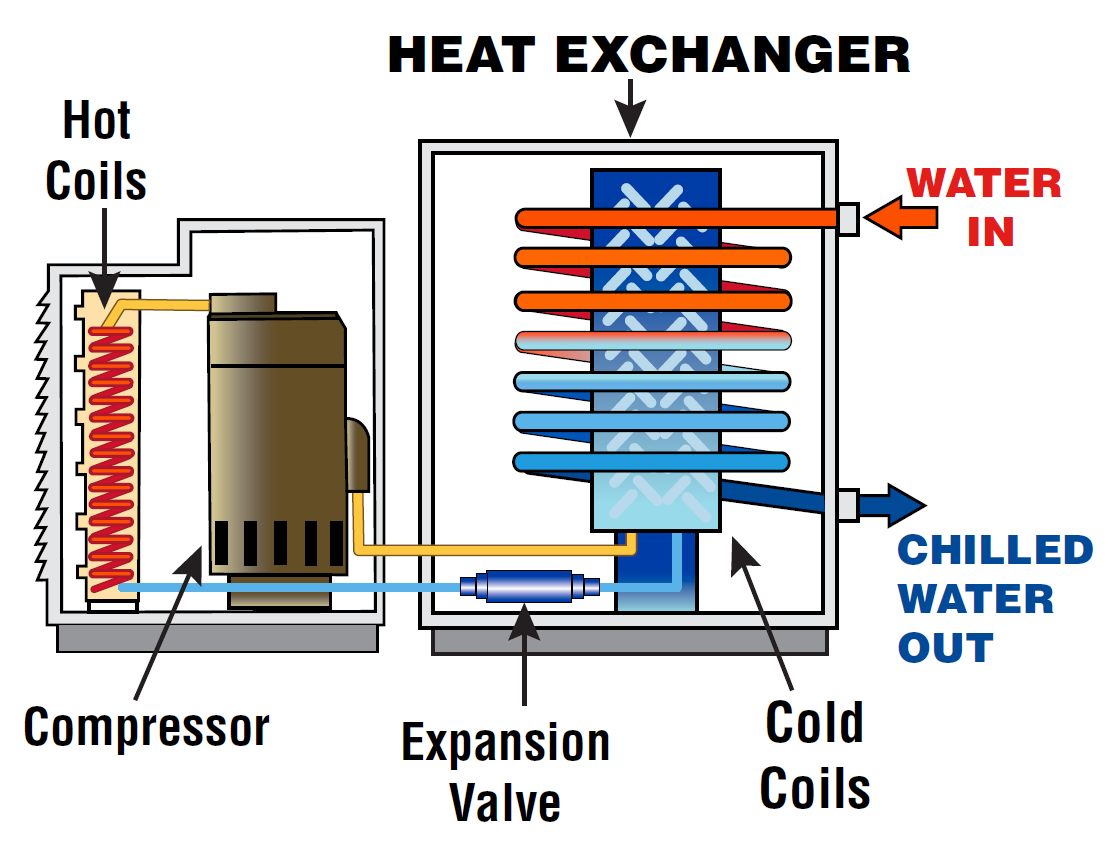

Hot water enters the tower, spreads over the fill, and comes into contact with moving air. A small portion of the water evaporates, removing heat from the remaining water, which then collects in the basin.

Fans are the heart of a mechanical draft cooling tower. They regulate airflow, allowing the system to adapt quickly to changes in heat load or ambient temperature.

Industrial facilities face unique cooling challenges:

High and variable heat loads

Limited installation space

Strict temperature control requirements

High reliability expectations

Mechanical draft cooling towers are designed specifically to meet these challenges head-on.

One of the biggest advantages of mechanical draft cooling towers is high thermal efficiency.

Because airflow is mechanically driven, it can be precisely controlled. This means optimal air-to-water contact, better evaporation, and more consistent cooling performance—even on hot, still days.

Think of it like using a fan to cool yourself versus standing still in warm air. The movement makes all the difference.

Mechanical draft cooling towers deliver high capacity without requiring massive structures.

Their compact footprint makes them ideal for:

Urban factories

Retrofit projects

Rooftop HVAC systems

Where space is limited, mechanical draft cooling towers shine.

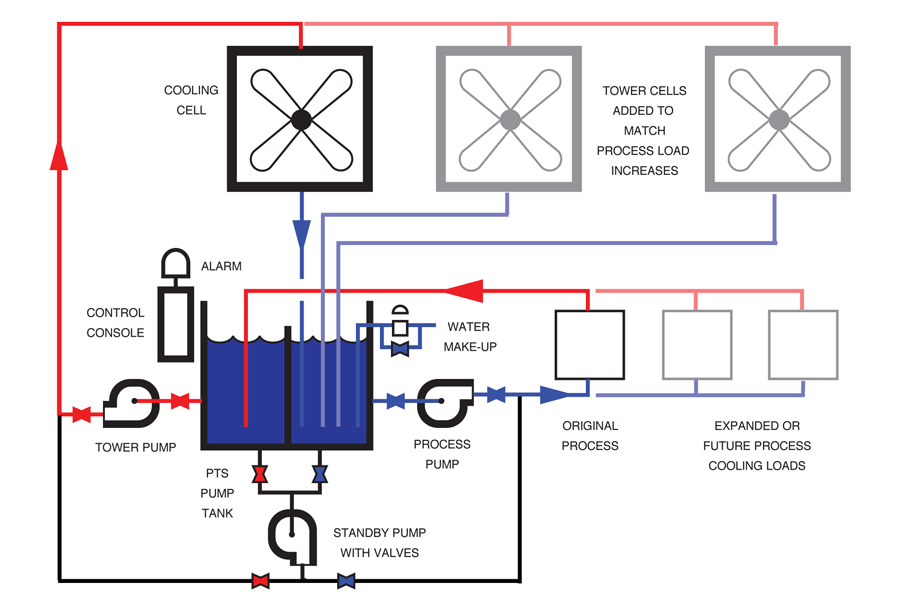

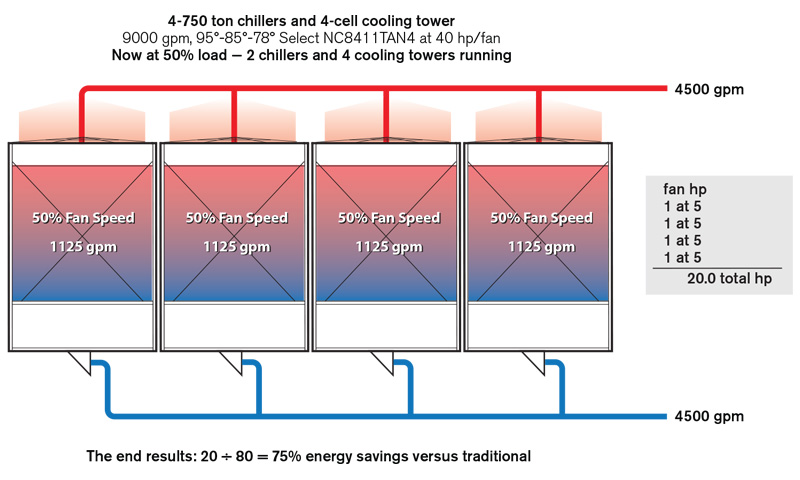

Industrial demand rarely stays constant.

Mechanical draft cooling towers can be:

Modular

Scalable

Customized for specific flow rates

Need more capacity next year? Add another cell. No need to rebuild the entire system.

In many industrial processes, a few degrees can make or break performance.

With variable-speed fans and smart controls, mechanical draft cooling towers can maintain stable outlet temperatures—even when process conditions change rapidly.

Natural draft cooling towers may look impressive, but they come at a price.

Mechanical draft cooling towers typically offer:

Lower construction costs

Shorter project timelines

Reduced civil engineering requirements

For most industrial projects, they provide the best balance between cost and performance.

Mechanical draft cooling towers are incredibly versatile.

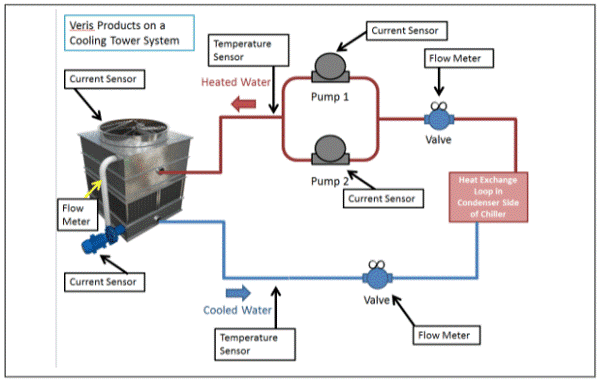

Used for auxiliary cooling, condenser cooling, and closed-loop systems.

Ideal for chillers, data centers, and large commercial buildings.

From chemicals to food processing, reliable cooling keeps production running smoothly.

Mechanical draft cooling towers are often factory-assembled or modular, allowing faster installation compared to large concrete structures.

This means quicker commissioning and faster return on investment.

Fans, fills, drift eliminators, and basins are easier to access, inspect, and replace. This reduces downtime and maintenance costs over the system’s lifetime.

In short:

Mechanical draft = control, flexibility, compact size

Natural draft = large scale, long construction, limited flexibility

For most industrial cooling needs, mechanical draft towers are the practical choice.

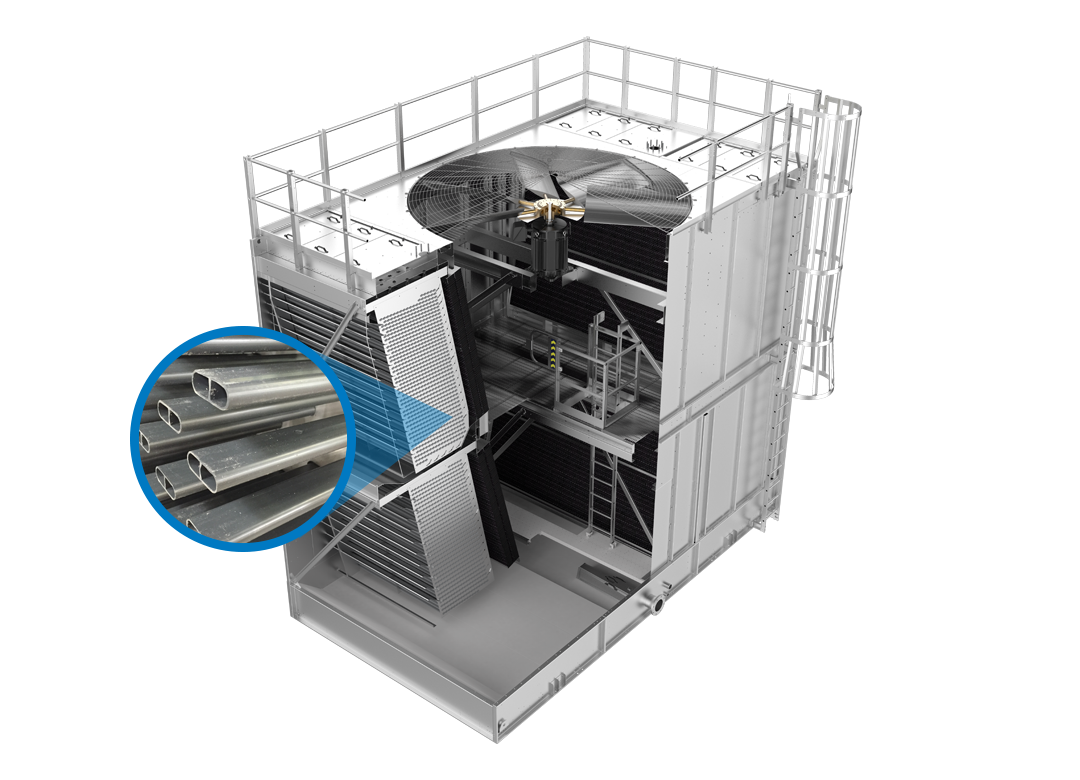

As an experienced cooling tower manufacturer, MACH Cooling designs mechanical draft cooling towers with:

High-efficiency fan systems

Optimized fill and airflow paths

Durable, corrosion-resistant materials

Custom solutions for industrial applications

Learn more at https://www.machcooling.com/

Mechanical draft cooling towers have earned their place in industrial cooling by delivering efficiency, flexibility, and reliability.

From compact design to precise temperature control, their advantages make them the go-to solution for modern industrial facilities. And when engineered by professionals like MACH Cooling, they provide long-term performance you can depend on.

Cooling Tower for Sale – High Efficiency, Factory Direct Supply

Cooling Tower Capacity Vs Load: Matching Performance To Demand

Best Cooling Tower for Energy Efficiency And Low Operating Cost

Approach Temperature Vs Range in Cooling Towers: Key Differences

American Chillers And Cooling Tower Systems: Quality, Performance, And Reliability