We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-02-07 Origin: Site

Dust may seem harmless at first glance, but in industrial cooling systems, it can quietly become one of the most destructive forces. In high-dust environments, cooling towers constantly pull airborne particles into the system, mixing them directly into circulating water. Over time, this dust buildup affects performance, increases costs, and shortens equipment life.

That’s exactly why a cooling tower sand filter is not optional in dusty locations—it’s essential. If your facility operates near mines, cement plants, construction zones, deserts, or heavy industrial areas, sand filtration can mean the difference between stable operation and constant headaches.

Cooling towers act like giant air washers. As large volumes of air move through the tower, dust, sand, pollen, and fine debris are pulled inside and absorbed by the circulating water.

In clean environments, this may not be a major concern. But in high-dust locations, the cooling tower is under nonstop assault. Dust accumulates day after day, slowly degrading water quality and system efficiency—often without immediate warning signs.

Think of dust like cholesterol in arteries. You don’t feel the problem at first, but over time, the damage becomes unavoidable.

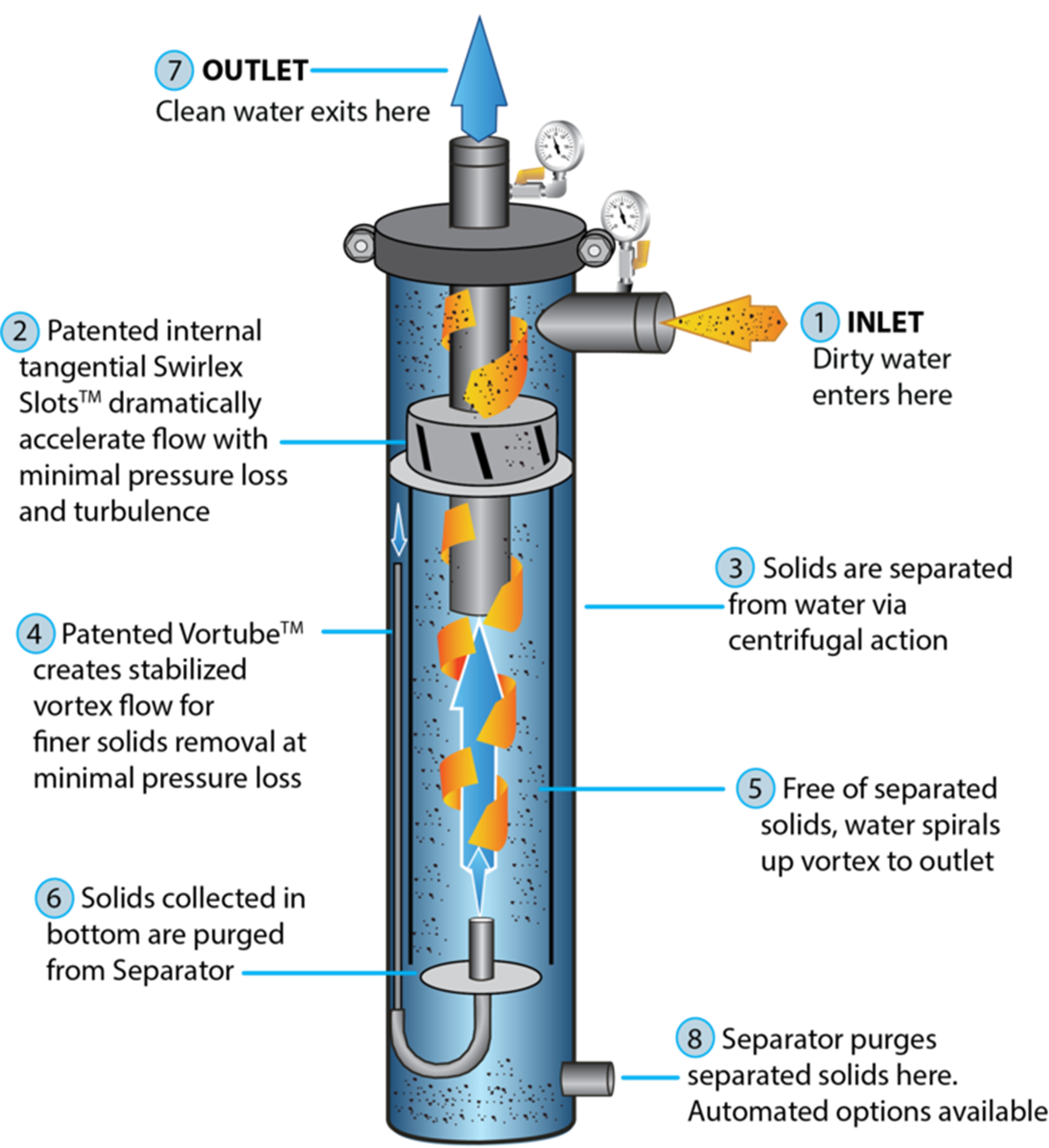

A cooling tower sand filter is a mechanical filtration system designed to remove suspended solids such as dust, sand, silt, and fine debris from circulating cooling water. Its core purpose is simple: maintain clean water to protect the entire cooling system.

By continuously removing solids, sand filters prevent contaminants from circulating repeatedly and causing long-term damage.

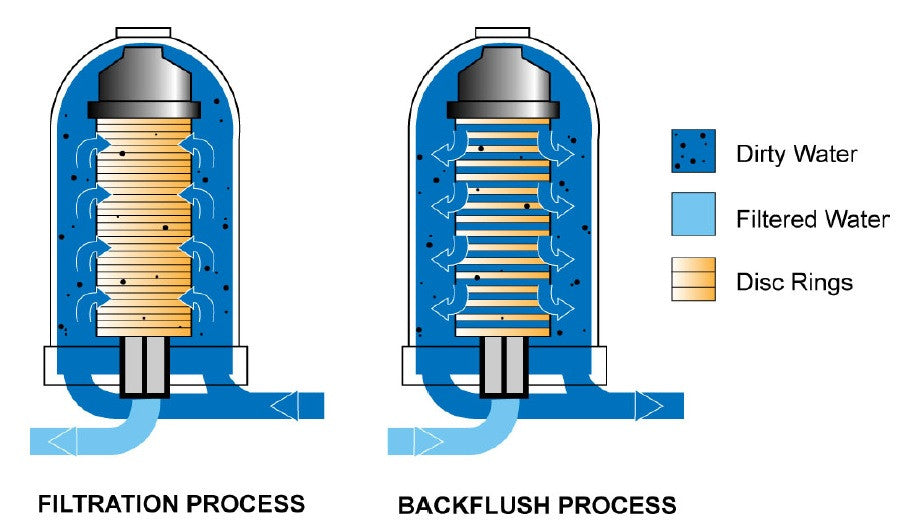

Sand filtration relies on layers of graded filter media. Water flows through the sand bed, and suspended particles become trapped between the grains. Clean water exits the filter, while dirt stays behind until it is removed during backwashing.

It’s a time-tested principle—simple, natural, and extremely reliable.

High-dust environments are common in:

Cement and concrete plants

Mining and mineral processing facilities

Steel mills and foundries

Desert and semi-arid regions

Industrial zones with constant construction activity

In these locations, airborne particles are unavoidable—and cooling towers capture them continuously.

Industries with outdoor processes and open-loop cooling systems experience the highest dust loads. Cooling towers in these settings often suffer accelerated fouling without proper filtration.

Dust doesn’t just make water look dirty—it actively degrades performance.

When suspended solids coat heat exchange surfaces, they act as insulation. This reduces heat transfer efficiency and forces fans, pumps, and chillers to work harder to achieve the same cooling effect.

It’s like trying to cool your house with the windows covered in plastic.

Dust particles provide surfaces for scale formation. Once fouling starts, it accelerates quickly, leading to clogged fill, blocked nozzles, and uneven water distribution.

Basic strainers and screens are designed to catch large debris, not fine dust. In high-dust environments, most harmful particles are small enough to pass straight through conventional filtration and circulate endlessly.

That’s why side stream sand filtration is the preferred solution—it continuously removes fine suspended solids before they accumulate.

A sand filter constantly cleans a portion of the circulating water, preventing dust from building up throughout the system. This keeps overall water quality stable even in extreme conditions.

Rather than filtering the entire system flow, side stream sand filters typically handle 5–15% of the circulation rate. This approach is energy-efficient while still delivering excellent water clarity.

Small flow, big impact.

Cleaner water leads to:

More consistent heat rejection

Reduced risk of unexpected shutdowns

Longer-lasting mechanical components

Stable water quality creates stable operations.

With fewer solids circulating:

Fill stays cleaner

Nozzles clog less often

Cleaning intervals are extended

Maintenance teams spend less time reacting and more time optimizing.

Dirty water forces higher blowdown rates to control total dissolved solids. By removing suspended solids early, sand filters allow systems to operate at higher cycles of concentration.

The result:

Reduced blowdown

Lower makeup water demand

Decreased chemical consumption

In water-scarce regions, these savings are significant.

Without sand filtration:

Rapid fouling

Rising chemical costs

Frequent maintenance shutdowns

With a cooling tower sand filter:

Clean, stable circulating water

Predictable performance

Lower total cost of ownership

The contrast becomes obvious within months of operation.

Sand filters are built for dirty conditions. Automatic backwashing removes accumulated solids from the sand media, restoring filtration efficiency without manual intervention.

Even in heavy dust environments, modern sand filters remain easy to operate and maintain.

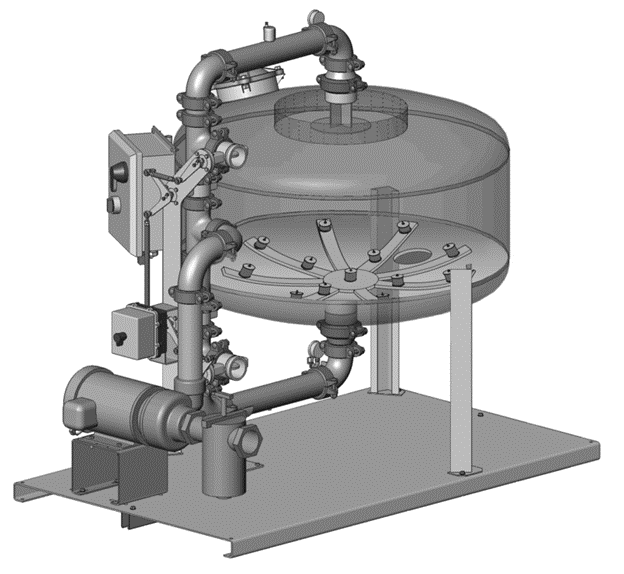

When designing or upgrading a system for dusty locations, key factors include:

Proper sand media selection

Correct side stream flow sizing

Automatic backwash control

Corrosion-resistant construction materials

Good design upfront prevents costly retrofits later.

Experienced manufacturers understand real operating conditions. Mach Cooling recommends integrating sand filtration into cooling tower systems operating in high-dust environments to ensure long-term reliability.

Their design philosophy focuses on:

Protecting heat transfer performance

Reducing operational risk

Simplifying maintenance for operators

More information is available at https://www.machcooling.com/.

Cooling tower sand filters are widely applied in:

Cement plants

Mining operations

Power stations

Industrial HVAC systems in desert regions

In all these cases, sand filtration consistently delivers cleaner water and more reliable operation.

High-dust environments are unforgiving. Without proper filtration, dust gradually erodes cooling tower performance, increases operating costs, and shortens equipment life.

A cooling tower sand filter acts as a protective shield—quietly removing contaminants, stabilizing water quality, and protecting your investment day after day.

If dust is unavoidable where you operate, sand filtration isn’t an upgrade.

It’s a necessity.

Industrial Applications of Cooling Tower Wastewater Treatment

Temporary Cooling Solutions: Trailer Mounted Cooling Towers in Construction Sites

How Cooling Tower Testing Helps Prevent Legionella And Other Risks

Cooling Tower Sump Accessories That Improve System Reliability

Essential Cooling Tower Safety Precautions Every Operator Should Know