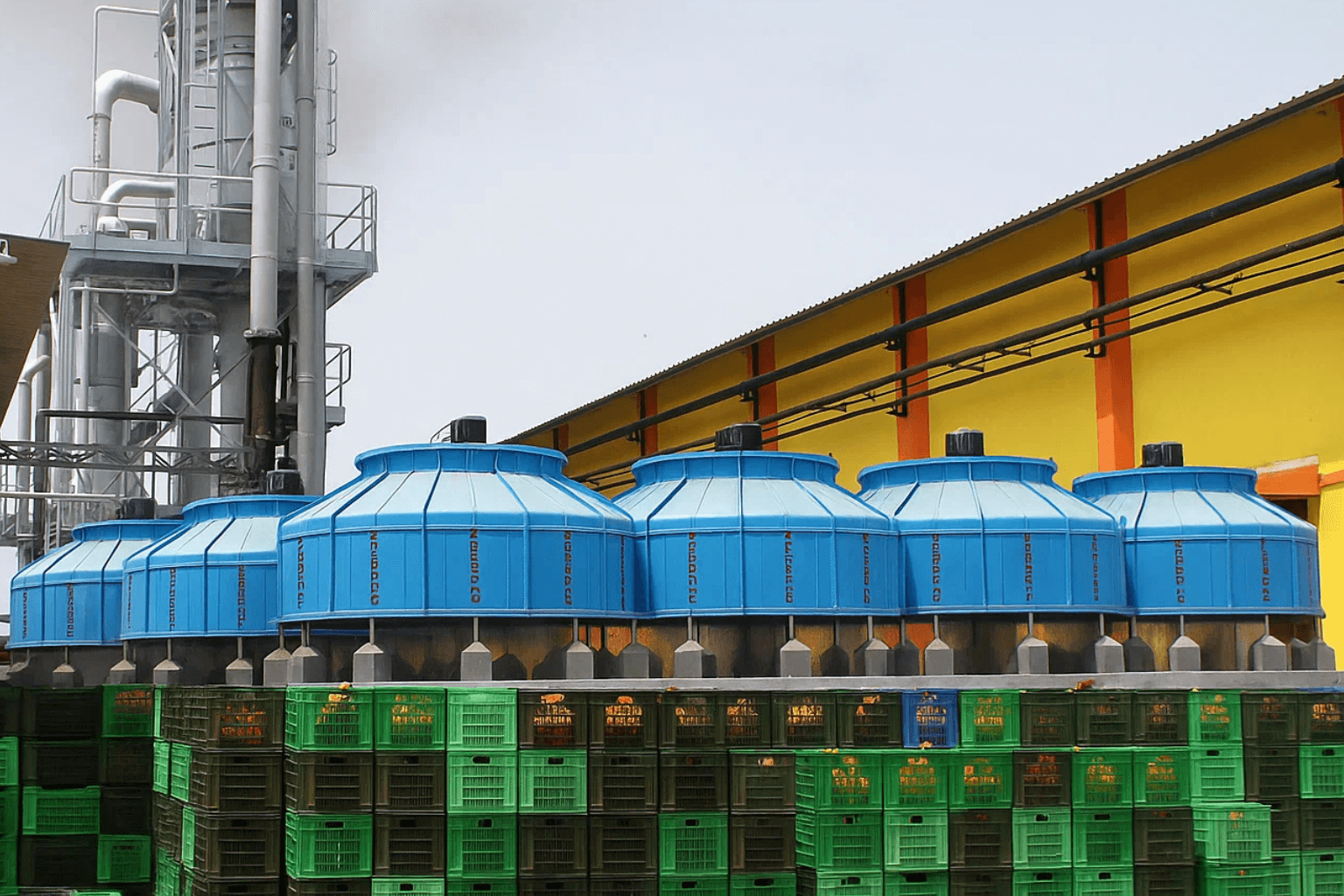

We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-02-07 Origin: Site

If you operate or manage an industrial cooling system, you already know one hard truth: scaling, fouling, and corrosion rarely show up alone. They’re like bad neighbors—once one moves in, the others usually follow.

That’s why modern facilities don’t just look for quick fixes anymore. They look for comprehensive cooling tower solutions that address the root causes, not just the symptoms. In this article, we’ll break down how smart cooling tower solutions help prevent scaling, control fouling, and minimize corrosion—while improving efficiency, reliability, and long-term operating costs.

Scaling occurs when dissolved minerals—primarily calcium and magnesium—precipitate out of the water and stick to heat transfer surfaces. Think of it like kettle scale, but on an industrial scale.

Common causes include:

High hardness makeup water

Elevated cycles of concentration

Poor chemical control

Once scale forms, heat transfer efficiency drops fast. Even a thin layer can significantly increase energy consumption.

Fouling is the unwanted buildup of biological growth, suspended solids, and organic matter. Unlike scale, fouling is often soft, slimy, and deceptively dangerous.

Sources of fouling include:

Dust and airborne contaminants

Algae and bacteria

Process leaks

Left untreated, fouling restricts water flow, harbors bacteria, and accelerates corrosion under deposits.

Corrosion is the gradual destruction of metal surfaces due to chemical or electrochemical reactions. In cooling towers, it’s usually driven by:

Oxygen-rich warm water

Improper pH control

Chlorides and sulfates

Microbiologically influenced corrosion (MIC)

Corrosion doesn’t just damage equipment—it can lead to unexpected shutdowns and costly replacements.

Treating scaling without addressing fouling is like mopping the floor while the tap is still running. Isolated solutions often shift the problem instead of solving it.

Modern cooling tower solutions take a holistic approach:

Water chemistry

Mechanical filtration

Material selection

Intelligent operation

An integrated solution ensures:

Stable water quality

Consistent heat transfer

Longer equipment lifespan

Lower total cost of ownership

Manufacturers like MACH Cooling (https://www.machcooling.com/) design systems with this big-picture mindset from the start.

Chemical treatment remains the backbone of scale prevention. Effective programs typically include:

Scale inhibitors

pH control agents

Dispersants

The key is precise dosing—too little invites scale, too much wastes money and risks corrosion.

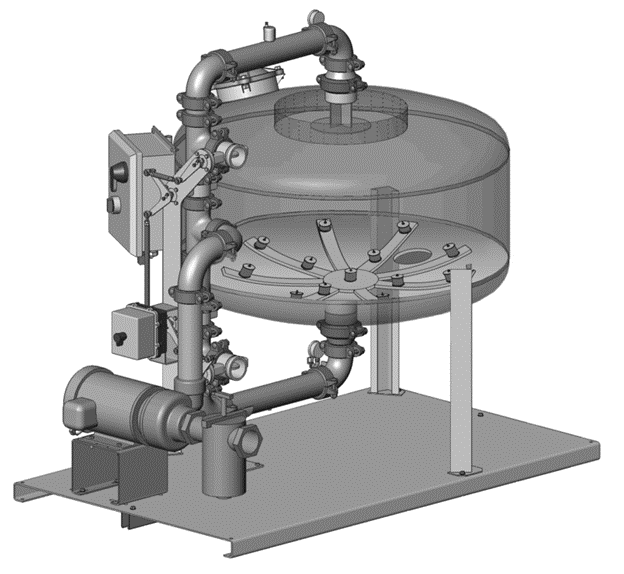

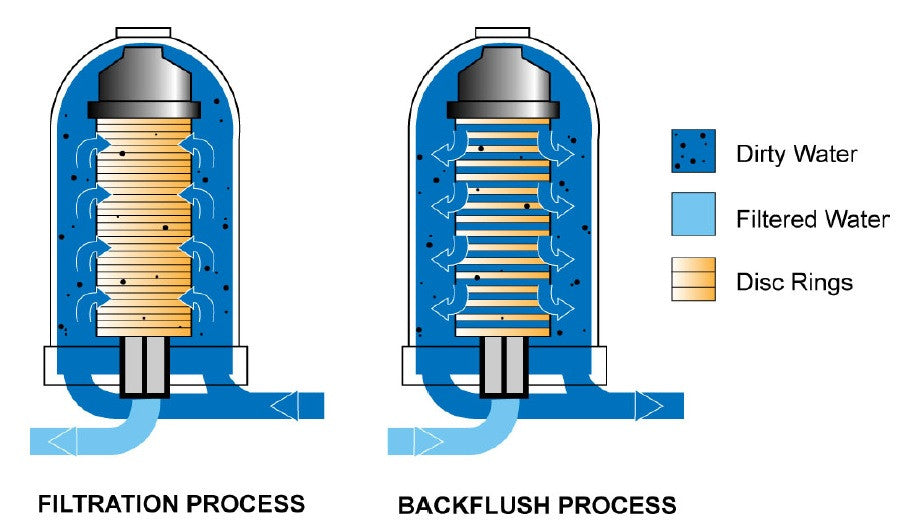

Side stream filtration removes suspended solids before they become scale nucleation points. Common options include:

Sand filters

Multimedia filters

Automatic self-cleaning filters

In dusty or industrial environments, this is one of the most cost-effective cooling tower solutions available.

Reducing hardness in makeup water directly lowers scale risk. Depending on site conditions, solutions may include:

Ion exchange softeners

Partial softening systems

Controlled blowdown optimization

Microbial growth thrives in warm, wet environments. Effective fouling control requires:

Oxidizing biocides

Non-oxidizing biocides

Alternating treatment programs

Consistency is everything—sporadic treatment only trains bacteria to fight back.

Filtration isn’t just for scale—it’s a frontline defense against fouling. Removing silt, fibers, and debris prevents:

Biofilm attachment

Sludge accumulation

Under-deposit corrosion

This is why many cooling tower solutions combine chemical and mechanical approaches.

Modern cooling tower designs reduce fouling by:

Improving water distribution

Eliminating dead zones

Using fouling-resistant fill materials

Companies like MACH Cooling engineer towers with maintenance-friendly layouts that simplify cleaning and inspection.

Not all cooling towers are created equal. Corrosion resistance starts with:

FRP structures

Hot-dip galvanized or stainless steel

Protective coatings

Choosing the right materials upfront is one of the smartest long-term cooling tower solutions.

Chemical inhibitors form protective films on metal surfaces, reducing corrosion rates. These programs are tailored based on:

Metallurgy

Water chemistry

Operating temperature

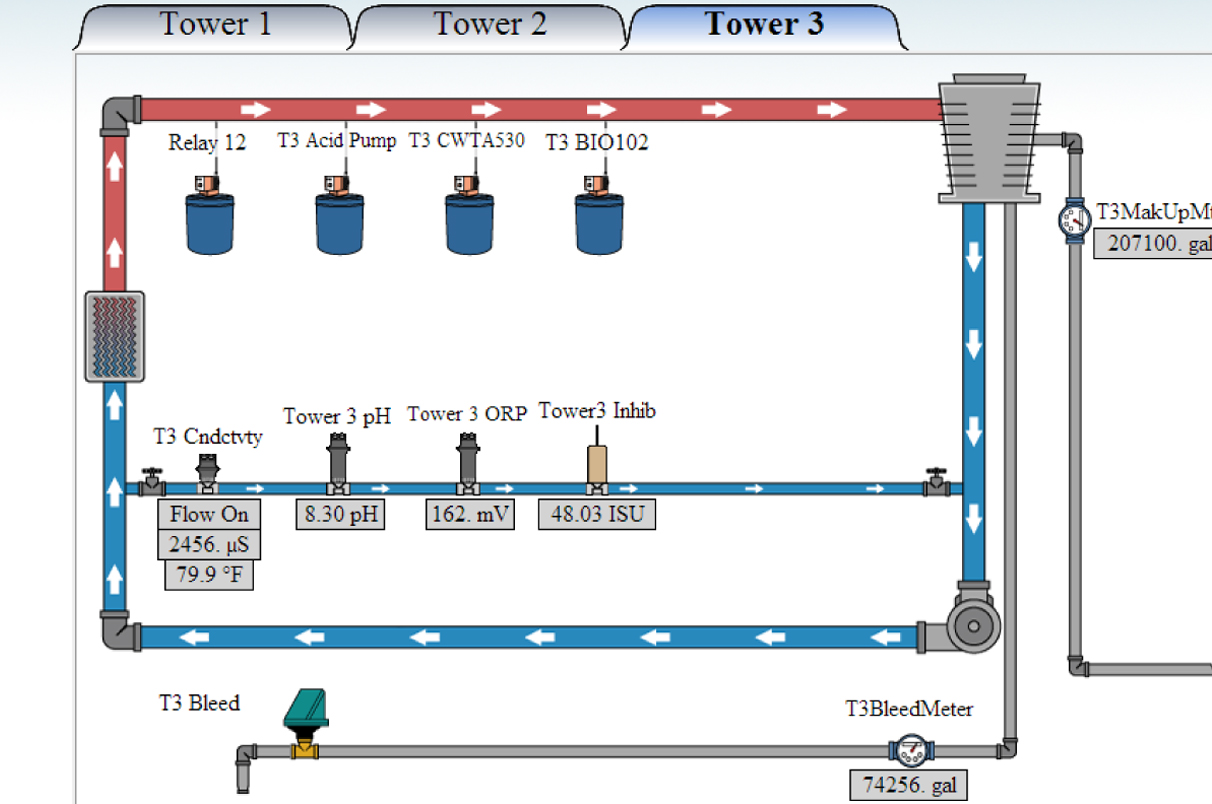

Automation transforms corrosion control from guesswork into science. Online monitoring systems track:

pH

Conductivity

ORP

Corrosion rates

Automated control ensures fast response and stable operation.

Hybrid systems combine wet and dry cooling to:

Reduce water consumption

Minimize plume

Improve seasonal efficiency

They’re especially valuable in regions with water restrictions.

Reducing drift loss means:

Less chemical loss

Lower environmental impact

Reduced corrosion around the tower

A small component with a big payoff.

Smart cooling tower solutions now integrate:

IoT sensors

Cloud-based analytics

Predictive alerts

Instead of reacting to failures, operators can prevent them.

These facilities demand:

High reliability

Robust materials

Redundant systems

Scaling or corrosion here isn’t just costly—it’s critical.

For HVAC-driven towers, priorities include:

Energy efficiency

Quiet operation

Compact footprints

Tailored cooling tower solutions ensure stable comfort and uptime.

Process contamination risks require:

Precise water chemistry control

Specialized materials

Strict fouling prevention

A cooling tower isn’t just equipment—it’s a system. Working with an experienced manufacturer like MACH Cooling ensures:

Proper design from day one

Customized cooling tower solutions

Long-term technical support

You can explore their engineered systems at https://www.machcooling.com/.

Before selecting a solution, ask:

Is it customized to my water quality?

Does it address scaling, fouling, and corrosion together?

What’s the long-term operating cost?

Good answers save years of trouble.

Even the best cooling tower solutions need attention. Regular inspections help detect:

Early scale formation

Fouling hotspots

Corrosion initiation

An informed operator is your first line of defense. Training ensures:

Proper chemical handling

Correct system adjustments

Faster problem detection

Scaling, fouling, and corrosion are inevitable challenges—but failure isn’t. With integrated cooling tower solutions, facilities can:

Improve heat transfer efficiency

Extend equipment lifespan

Reduce water, energy, and maintenance costs

The key is thinking beyond quick fixes and choosing system-level strategies supported by experienced manufacturers like MACH Cooling. When cooling tower solutions are done right, the entire operation runs cooler, cleaner, and smarter.

Industrial Applications of Cooling Tower Wastewater Treatment

Temporary Cooling Solutions: Trailer Mounted Cooling Towers in Construction Sites

How Cooling Tower Testing Helps Prevent Legionella And Other Risks

Cooling Tower Sump Accessories That Improve System Reliability

Essential Cooling Tower Safety Precautions Every Operator Should Know