We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-02-09 Origin: Site

The North America evaporative cooling tower market is entering a critical growth phase. From aging industrial infrastructure to rising energy efficiency standards, cooling towers are no longer just background equipment—they are strategic assets.

In the United States and Canada, evaporative cooling towers are widely used in power plants, manufacturing facilities, data centers, refineries, and large commercial buildings. As water and energy costs rise, operators are paying closer attention to system efficiency, lifecycle cost, and sustainability.

So what’s driving demand? And where is the market headed next? Let’s break it down.

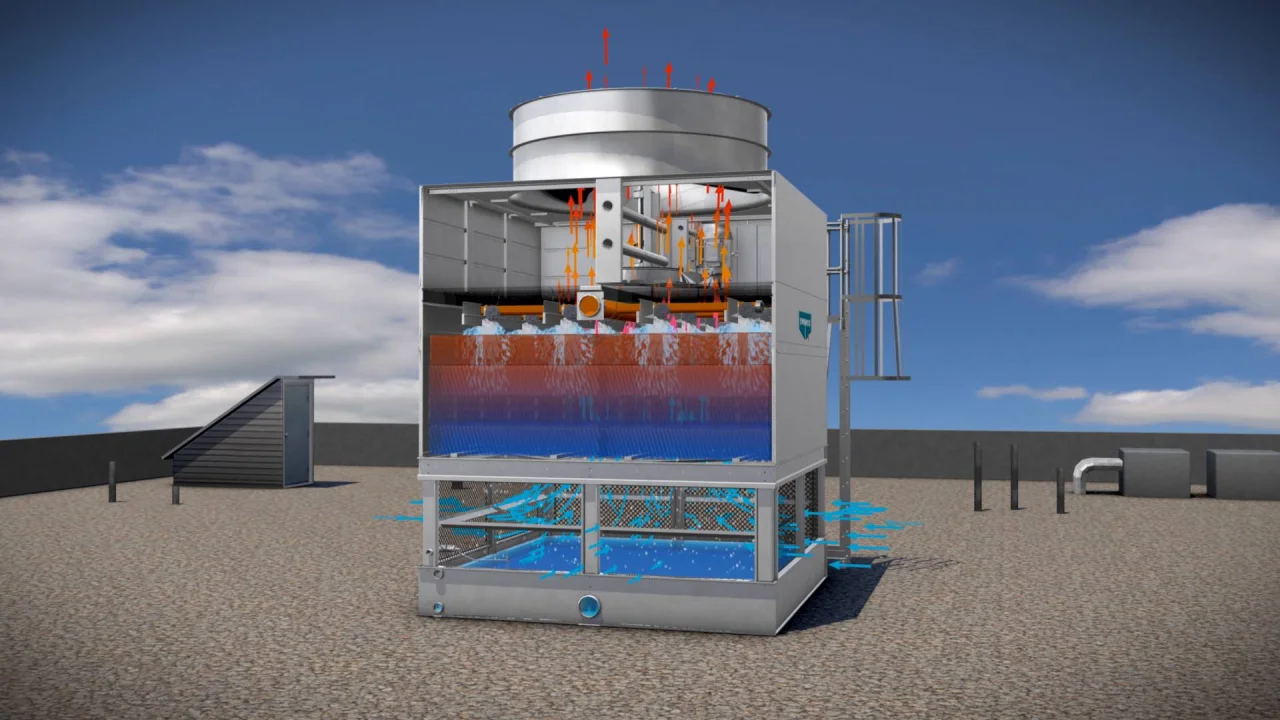

An evaporative cooling tower removes heat from water by using evaporation. Warm process water flows through the tower and comes into contact with air. As a small portion of water evaporates, it absorbs heat—cooling the remaining water before it’s recirculated.

Think of it like sweat cooling your skin on a hot day. Simple physics, powerful results.

Compared with dry cooling systems, evaporative cooling towers offer:

Higher thermal efficiency

Lower energy consumption

Proven reliability in high-load environments

That’s why they remain the preferred solution across North America’s industrial and commercial sectors.

The North America evaporative cooling tower market continues to grow steadily, supported by:

Industrial modernization

Expansion of data centers

Retrofitting of aging HVAC systems

Stricter energy-efficiency regulations

While growth is moderate compared to emerging markets, demand is stable, long-term, and technology-driven.

United States – Largest market with strong demand from power generation, chemicals, and commercial HVAC

Canada – Growth driven by industrial projects and district cooling systems

Manufacturing sectors such as chemicals, oil & gas, food processing, and metals rely heavily on evaporative cooling towers to maintain stable operations.

Many facilities are replacing old, inefficient towers with high-performance, corrosion-resistant designs.

Thermal and nuclear power plants are among the largest users of cooling towers in North America. Even with renewable energy growth, conventional power generation still depends on reliable evaporative cooling systems.

Data centers are exploding across the U.S. Driven by AI, cloud computing, and digital transformation, these facilities require precise and energy-efficient heat rejection—a perfect fit for modern evaporative cooling towers.

Water usage, drift loss, and chemical discharge are under increasing scrutiny. Regulations from agencies like the EPA push operators toward more efficient tower designs.

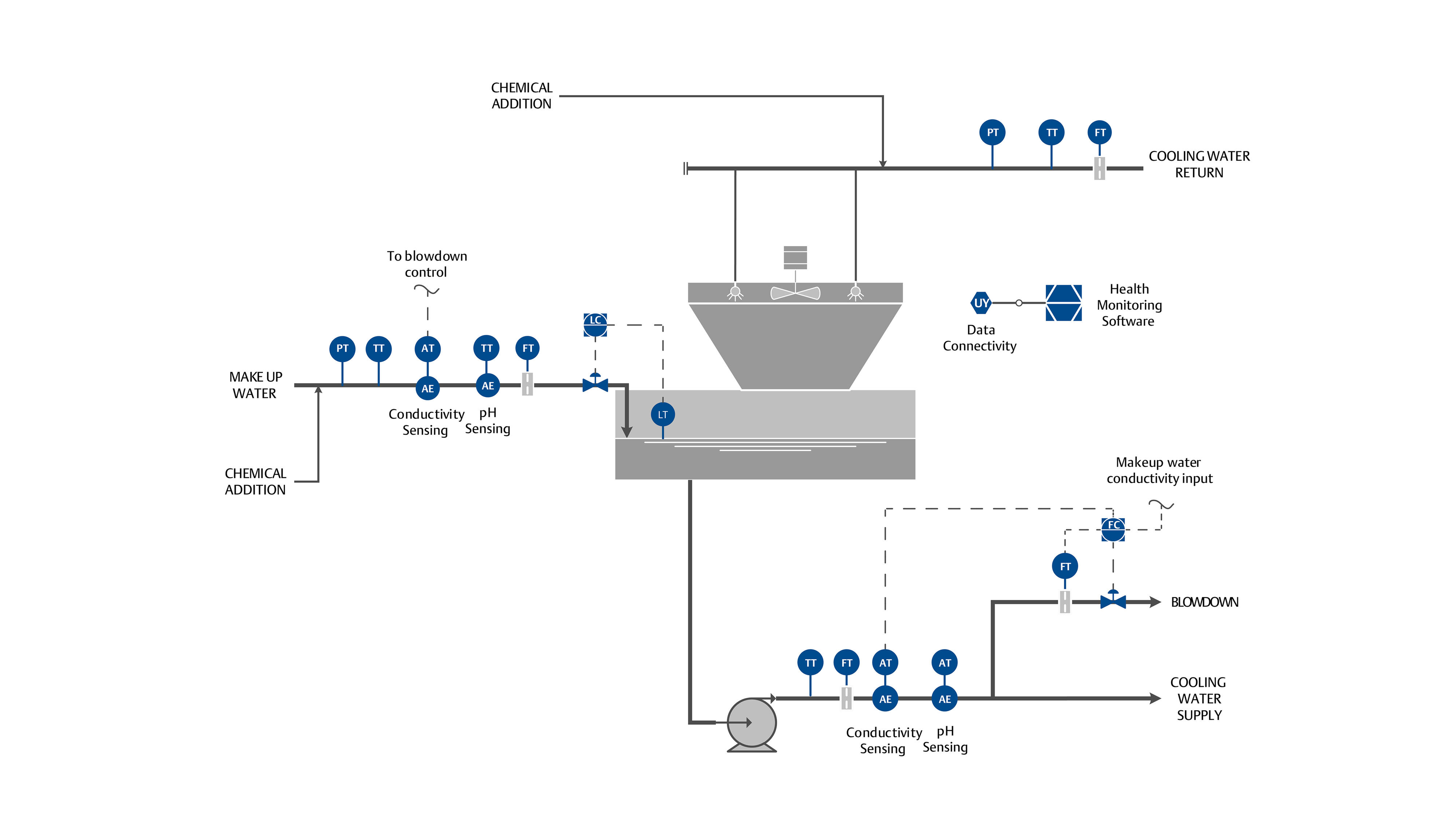

Modern towers now integrate:

High-efficiency drift eliminators

Optimized fill media

Advanced water treatment systems

These features reduce water waste while maintaining performance.

Evaporative cooling towers consume significantly less electricity than air-cooled alternatives, helping facilities meet carbon reduction goals.

Digital sensors now monitor:

Water level

Temperature differentials

Blowdown rates

Fan performance

Smart controls help operators reduce operating costs and prevent failures.

New materials like FRP, stainless steel, and concrete hybrid structures improve durability, especially in harsh climates.

Heavy industries demand rugged, high-capacity towers with long service life and minimal downtime.

Hospitals, airports, shopping malls, and office towers rely on evaporative cooling towers for central HVAC systems.

Urban areas increasingly adopt district cooling, where large centralized cooling towers serve multiple buildings efficiently.

In drought-prone regions, water availability can limit cooling tower operation, pushing demand for high-efficiency and low-makeup-water designs.

Proper maintenance is critical. Modern tower designs focus on easier access, better airflow, and improved hygiene.

North American buyers prioritize:

Proven engineering expertise

Compliance with U.S. standards (CTI, ASHRAE)

Long-term service and support

Customization for specific applications

Established manufacturers with global experience and strong engineering capabilities are better positioned to meet these demands.

As an experienced cooling tower manufacturer, Mach Cooling provides evaporative cooling tower solutions tailored to industrial, power, and commercial applications.

With a focus on:

Energy efficiency

Water-saving design

Robust materials

Customized engineering

Mach Cooling supports projects aligned with North American performance expectations and sustainability goals. Learn more at https://www.machcooling.com/.

The market is shifting from simple equipment supply to intelligent, optimized cooling solutions.

Many existing facilities are upgrading aging towers rather than building new plants—creating strong retrofit opportunities.

The North America evaporative cooling tower market is defined by stability, technological progress, and rising efficiency standards. While not the fastest-growing region globally, it remains one of the most demanding—and rewarding—markets for manufacturers and suppliers.

As industries modernize and sustainability becomes non-negotiable, evaporative cooling towers will continue to play a vital role in keeping North America cool, efficient, and competitive.

Temporary Cooling Solutions: Trailer Mounted Cooling Towers in Construction Sites

North America Evaporative Cooling Tower Market: Trends And Demand Drivers

What Is A Cooling Tower Water Level Sensor And How Does It Work?

Cooling Tower Water Conservation: How To Cut Water And Operating Costs

Industrial Applications of Cooling Tower Wastewater Treatment

How Cooling Tower Testing Helps Prevent Legionella And Other Risks

Cooling Tower Sump Accessories That Improve System Reliability